Content last revised on November 14, 2025

6MBP20JB060 IGBT PIM Module | 600V 20A | Fuji Electric

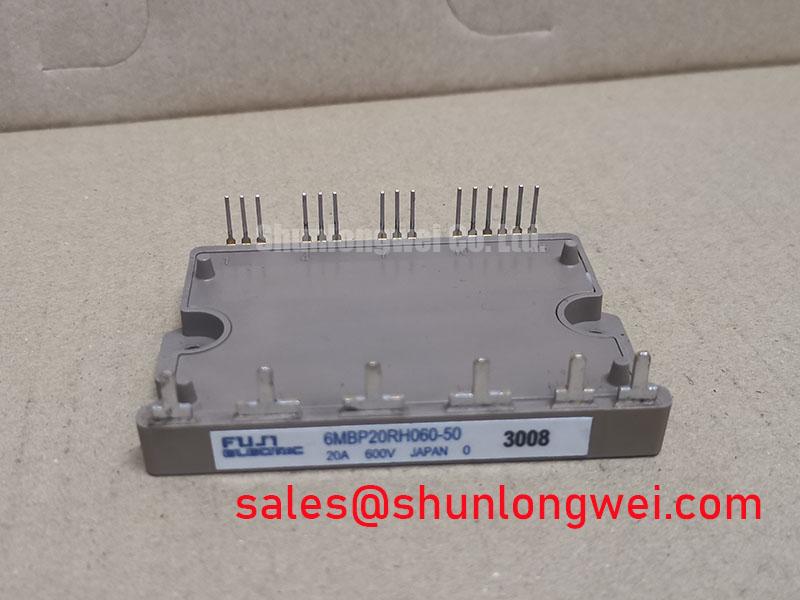

Product Overview: 6MBP20JB060

The Fuji Electric 6MBP20JB060 is a Power Integrated Module (PIM) designed to accelerate the development of compact, low-power motor drives. This device consolidates a three-phase converter, a three-phase inverter, and a brake circuit into a single, thermally efficient package. By integrating these core functions, it directly addresses the engineering challenge of reducing component count and simplifying PCB layout. What is the topology of the 6MBP20JB060? It is a 7-in-1 PIM with a converter, inverter, and brake circuit, streamlining the entire power stage design.

- Top Specs: 600V | 20A | VCE(sat) 1.70V (typ)

- Key Benefits: Reduced Bill of Materials (BOM), simplified assembly process.

Data-Informed Selection: PIM Sizing and Topology

Evaluating a Power Integrated Module (PIM) like the 6MBP20JB060 requires looking beyond individual transistor ratings to the overall system value. As a distributor, we provide the following data points to support your engineering assessment. This information is intended to help clarify how this module's characteristics fit within different design constraints, allowing your team to make a well-informed decision based on factual performance metrics.

Comparative Data for System Evaluation:

- Integration Level: The 6MBP20JB060 offers a 7-in-1 configuration (3-phase rectifier + 3-phase inverter + brake chopper). This level of integration is typically compared against using separate converter and inverter modules or a full discrete component design. The primary trade-off is between the design flexibility of discrete components and the assembly speed and reliability of a highly integrated solution.

- Current Rating Context: The 20A collector current (Ic) rating is suitable for AC motor applications generally up to 2.2 kW. For systems requiring higher power, a component with a greater current capacity, such as the 6MBP50VBA120-50, may be considered.

- Voltage Class: With a collector-emitter voltage (VCES) of 600V, this module is specified for operation on 200-240V AC lines, common in small industrial machinery, automation, and commercial appliances. It provides a standard safety margin for these applications.

Anatomy of Integration: Inside the 6MBP20JB060

The fundamental design philosophy of the 6MBP20JB060 centers on functional consolidation to simplify the power electronics design process. This is achieved by co-packaging multiple semiconductor stages that would traditionally occupy significant PCB real estate as separate components.

The 7-in-1 Power Core

At its heart, the module contains three distinct sections: a three-phase diode bridge rectifier for AC-to-DC conversion, a three-phase IGBT inverter for DC-to-AC variable frequency output, and a single IGBT with a freewheeling diode for the brake chopper circuit. This architecture eliminates the need for numerous interconnects between stages, which in turn reduces stray inductance and potential EMI radiation sources—a critical consideration for achieving EMC compliance.

Integrated Thermal Feedback

A key feature that aids system integration is the built-in NTC thermistor. This component provides a direct, real-time measurement of the module's case temperature. How does the 6MBP20JB060 simplify thermal design? Its integrated thermistor provides direct case temperature feedback for control and protection. This enables the implementation of precise over-temperature protection and sophisticated thermal management strategies within the drive's control logic without the need to mount and wire an external temperature sensor, saving both space and assembly steps.

Deployment Snapshot: Streamlining VFD Assembly

Consider a scenario involving the production of compact variable frequency drives (VFDs) for conveyor belt systems. A traditional design approach would involve sourcing and mounting a bridge rectifier, six discrete IGBTs with their anti-parallel diodes, a separate chopper IGBT for braking, and an NTC thermistor. This process requires complex PCB routing, multiple heatsink mounting procedures, and extensive testing for each power stage.

By incorporating the 6MBP20JB060, the assembly is transformed. The entire power stage is mounted in a single step onto one heatsink. The number of power connections on the PCB is drastically reduced, minimizing potential soldering defects. The integrated thermistor provides a plug-and-play solution for thermal monitoring. This shift from a component-level to a module-level assembly methodology can significantly reduce production time and labor costs, directly impacting the total cost of ownership (TCO) for the final product.

Application Focus: Maximizing Value in Compact Systems

The integrated nature of the Fuji Electric 6MBP20JB060 delivers the most significant advantages in applications where space, assembly efficiency, and reliability are primary design drivers. Its architecture is particularly well-suited for a range of low-power motion control systems.

The module is an effective solution for:

- Small-Scale VFDs: Powering AC induction motors in applications like packaging machinery, fans, and pumps where compact drive dimensions are essential.

- Servo Drives: In the lower power range for robotics and automation, where reducing the physical footprint of the drive electronics allows for more compact machine designs.

- General-Purpose Inverters: For applications requiring a complete, tested power stage to accelerate the product development timeline.

For low-power motor drives under 2.2kW requiring rapid development, the 6MBP20JB060's integrated topology offers the most direct path to production. Understanding the fundamentals of how these devices function is key to successful implementation; you can explore this further in our guide on IGBT working principles.

Beyond the BOM: The Strategic Merit of Integrated Power Stages

Adopting an integrated module like the 6MBP20JB060 extends beyond immediate component cost savings. It represents a strategic decision that impacts the entire product lifecycle. By simplifying the design, procurement, and manufacturing processes, companies can enhance their agility and respond more quickly to market demands. This modular approach allows engineering teams to focus on higher-level control algorithms and software features—the very elements that often differentiate a product in a competitive marketplace. The reliability inherent in a factory-tested, integrated module also contributes to a lower rate of field failures, protecting brand reputation and reducing warranty-related expenses. For a broader view on the role of these components, consider reading IGBT Modules: The Backbone of High-Efficiency Power Systems.

Key Performance Indicators: 6MBP20JB060

The following parameters are critical for system-level design and thermal analysis. This curated list highlights the specifications most relevant to the module's application in compact motor drives. For a complete list of specifications, please download the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 600 V |

| Collector Current (Ic) @ Tc=80°C | 20 A |

| Collector-Emitter Saturation Voltage (Vce(sat)) @ Ic=20A | 1.70 V (Typical) / 2.20 V (Max) |

| Power Dissipation per IGBT (Pc) | 70 W |

| Thermal Resistance, Junction to Case (Rth(j-c)) per IGBT | 5.0 °C/W (Max) |

| Short Circuit Withstand Time (Tsc) | ≥ 10 µs |

Download the Datasheet for complete technical specifications.

Technical Inquiries on the 6MBP20JB060

What is the primary engineering benefit of the integrated brake chopper?

The integrated brake chopper simplifies the implementation of dynamic or regenerative braking in motor drive applications. It allows the system to safely dissipate energy from a decelerating motor without requiring an external, separately mounted chopper module, thus saving space, reducing wiring complexity, and lowering the overall component count.

How should thermal management be approached for this PIM?

Effective thermal management involves mounting the module's insulated metal baseplate to an appropriately sized heatsink using a quality thermal interface material (TIM). The integrated NTC thermistor should be connected to the drive's control circuit to monitor the case temperature. This data can be used to trigger fan control or, in critical conditions, fault shutdowns to protect the module. The thermal resistance (Rth) acts like the diameter of a drainpipe for heat; a lower value means a wider pipe, allowing heat to escape the chip more easily.

Is this module suitable for high-frequency switching applications?

The 6MBP20JB060 is designed for motor control applications, which typically operate at switching frequencies in the range of a few kHz up to around 15 kHz. While it is not optimized for very high-frequency applications like resonant converters, its switching characteristics are well-balanced for achieving high efficiency and low EMI in its intended VFD and servo drive applications. Refer to the Eon and Eoff values in the datasheet to calculate switching losses for your specific operating frequency.

Strategic Outlook

The move towards higher levels of integration in power electronics is a persistent trend, driven by the continuous demand for smaller, more efficient, and cost-effective systems. Devices like the Fuji Electric 6MBP20JB060 exemplify this shift, offering a clear path to reducing design complexity and accelerating time-to-market. As automation and electrification expand into new areas, such modular, pre-validated power stages will become increasingly crucial for enabling rapid innovation and deployment. Investing in an integrated platform allows engineering resources to be allocated towards software and system-level features, which are often the key differentiators in today's advanced industrial and commercial products.