Content last revised on November 15, 2025

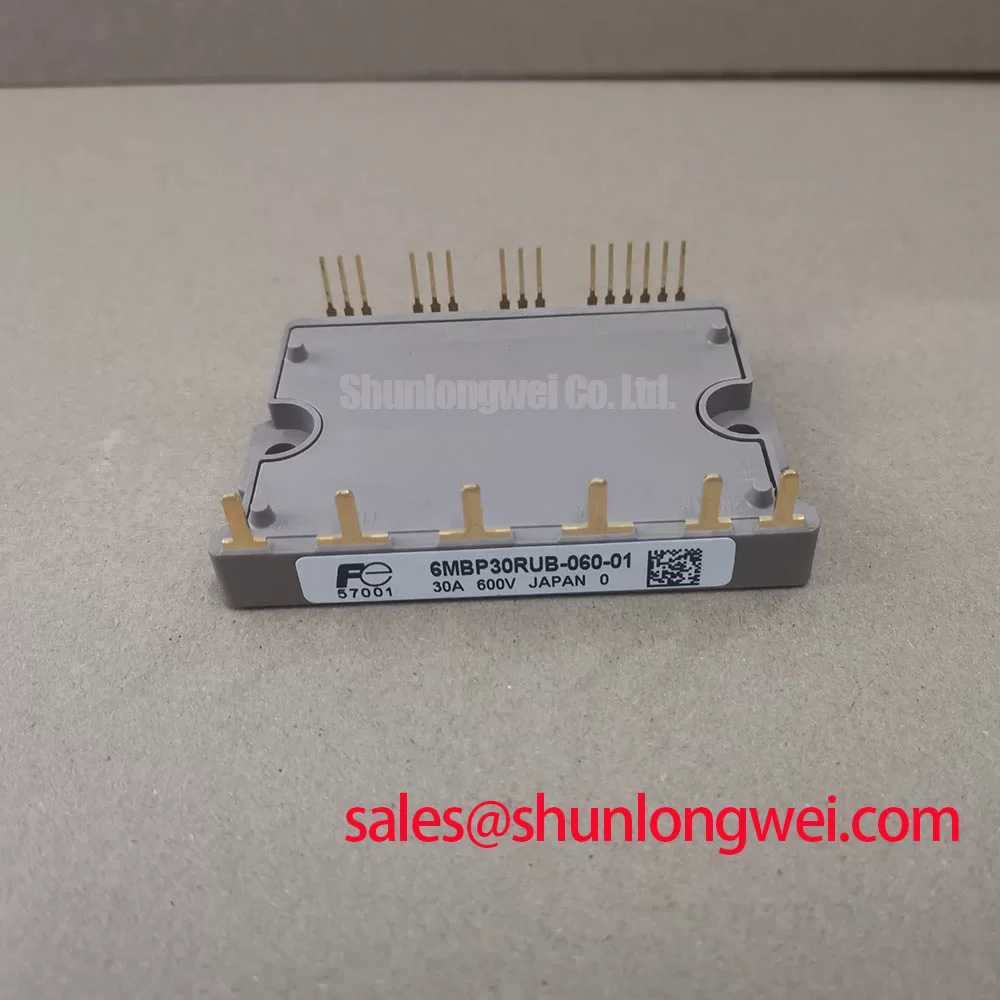

Fuji 6MBP100RTC060-01: 100A 600V Integrated IGBT PIM

Technical Deep Dive into Integrated Power Stages

The Fuji Electric 6MBP100RTC060-01 is an IGBT Power Integrated Module (PIM) designed to accelerate development cycles by consolidating a complete AC drive power stage into a single, thermally optimized package. With core specifications of 600V / 100A for its inverter and brake sections, this module offers a streamlined path to compact system design. Key benefits include a drastically reduced component count and simplified thermal management. For engineers deciding between discrete components and a consolidated module, a PIM offers significant advantages in assembly speed and reduced parasitic inductance, directly contributing to improved system reliability and performance.

Evaluating Integration: 6MBP100RTC060-01 vs. Discrete Architectures

When evaluating power stage solutions, design teams must weigh the trade-offs between discrete components and integrated modules. The 6MBP100RTC060-01 provides a clear data point for this analysis. A discrete approach, while offering component-level flexibility, requires separate sourcing, placement, and thermal management for the input rectifier, brake chopper, and three-phase inverter. In contrast, this PIM consolidates all these functions onto a single isolated baseplate. This not only reduces the physical footprint but also minimizes parasitic inductance between stages—a critical factor in mitigating voltage overshoots during high-frequency switching. For systems where time-to-market and assembly consistency are priorities, an integrated solution provides a distinct advantage. For applications requiring higher current handling, the 6MBP150RTC060 offers a similar integrated topology with a 150A rating.

Core Specifications for System Integration

The technical parameters of the 6MBP100RTC060-01 are specified to facilitate straightforward integration into compact power conversion systems. All ratings are provided at a case temperature (Tc) of 25°C unless otherwise noted. For a comprehensive understanding of all parameters, please refer to the official datasheet.

| Parameter | Condition | Value |

|---|---|---|

| Inverter Section | ||

| Collector-Emitter Voltage (Vces) | 600 V | |

| Continuous Collector Current (Ic) | Tc = 80°C | 100 A |

| Collector-Emitter Saturation Voltage (Vce(sat)) | Ic = 100A, Vge = 15V | 2.8 V (Max) |

| Brake Section | ||

| Continuous Collector Current (Ic) | Tc = 80°C | 100 A |

| Converter Section (Diode Rectifier) | ||

| Repetitive Peak Reverse Voltage (Vrrm) | 1200 V | |

| Average Forward Current (If(AV)) | 100 A | |

| Thermal Characteristics | ||

| Operating Junction Temperature (Tj) | +150 °C | |

| Thermal Resistance (Rth(j-c)) | IGBT (Inverter) | 0.24 °C/W |

Inside the PIM: A Consolidated Power Stage

The internal architecture of the 6MBP100RTC060-01 is its defining feature. It integrates three critical power electronics functions into one housing:

- Three-Phase Diode Bridge Rectifier: Converts the incoming AC supply into a DC bus voltage.

- Three-Phase IGBT Inverter: A six-pack IGBT configuration that synthesizes the variable frequency, variable voltage output to drive a motor.

- Brake Chopper: A single IGBT and freewheeling diode circuit used for dynamic braking, safely dissipating regenerative energy from the motor.

This level of integration simplifies not just the electrical layout but also the mechanical assembly. What is the main benefit of the integrated thermistor? Direct and accurate monitoring of the module's operating temperature, which is essential for implementing over-temperature protection and ensuring long-term reliability. Further details on system design considerations can be explored in our guide on IPM vs. Discrete IGBTs.

A Blueprint for Compact Drive Design

A common deployment for the 6MBP100RTC060-01 is in the development of compact Variable Frequency Drives (VFDs). In a typical scenario, an OEM is tasked with creating a new motor controller that is 25% smaller than the previous generation. Using this PIM, the engineering team can immediately eliminate the space and assembly complexity of a separate rectifier module and brake IGBT. The design process is streamlined: a single heatsink is selected, the busbar connections are simplified, and the gate drive and control board can be designed around a single power component. This consolidation is a key enabler for achieving higher power density.

Accelerating Time-to-Market with PIM Topology

The adoption of Power Integrated Modules (PIMs) like the 6MBP100RTC060-01 reflects a broader industry trend toward modularity and design efficiency. For manufacturers of industrial automation equipment, servo drives, and general-purpose inverters, reducing the development timeline is a significant competitive advantage. By using a pre-validated, integrated power stage, engineers can bypass the intricate process of selecting, matching, and laying out dozens of discrete power components. This allows them to focus resources on higher-level tasks such as control software development, user interface design, and system connectivity, ultimately leading to a faster product launch.

Target Application Environments

The highly integrated nature of the 6MBP100RTC060-01 makes it well-suited for applications where space, assembly cost, and design simplicity are primary engineering drivers. Its electrical characteristics support robust performance in a variety of power conversion systems.

- Compact Motor Drives: The all-in-one configuration is ideal for small to medium-sized VFDs and servo drives used in robotics, CNC machinery, and conveyor systems.

- General-Purpose Inverters: Suitable for standalone power conversion units where minimizing physical volume and manufacturing complexity is crucial.

- Industrial Automation Systems: Its robust construction supports deployment in factory automation equipment requiring reliable motor control.

For AC motor drives up to 37 kW requiring minimal footprint, the 6MBP100RTC060-01's integrated topology presents a more space-efficient solution than a multi-component discrete design.

Technical Inquiries on the 6MBP100RTC060-01

Our engineering audience frequently has specific questions about implementing integrated modules. Here are some key considerations:

- How is thermal management handled for the integrated rectifier and inverter sections?The module is designed with a single, electrically isolated baseplate that transfers heat from all internal semiconductor chips (rectifier diodes, inverter IGBTs, brake IGBT) to a common heatsink. While the sections are thermally coupled, the datasheet provides separate thermal resistance (Rth) values for each section. Effective thermal design requires a heatsink sized to handle the combined power loss from all concurrently operating sections, ensuring the maximum junction temperature of 150°C is not exceeded.

- What are the key considerations for the gate drive design given the integrated nature of this PIM?A successful gate drive design must accommodate all seven IGBTs (six for the inverter, one for the brake). Key considerations include providing a stable, isolated power supply for each gate driver, ensuring low-inductance connections to the gate and emitter terminals, and implementing appropriate protection features like under-voltage lockout (UVLO). Since the module uses conventional IGBT technology from its era, a standard gate drive voltage of +15V for turn-on and a small negative voltage (e.g., -5V to -10V) for turn-off is recommended to ensure noise immunity.

To further analyze if the 6MBP100RTC060-01 is the appropriate component for your specific design constraints, please consult the complete product datasheet or contact our technical support team for assistance with your application.