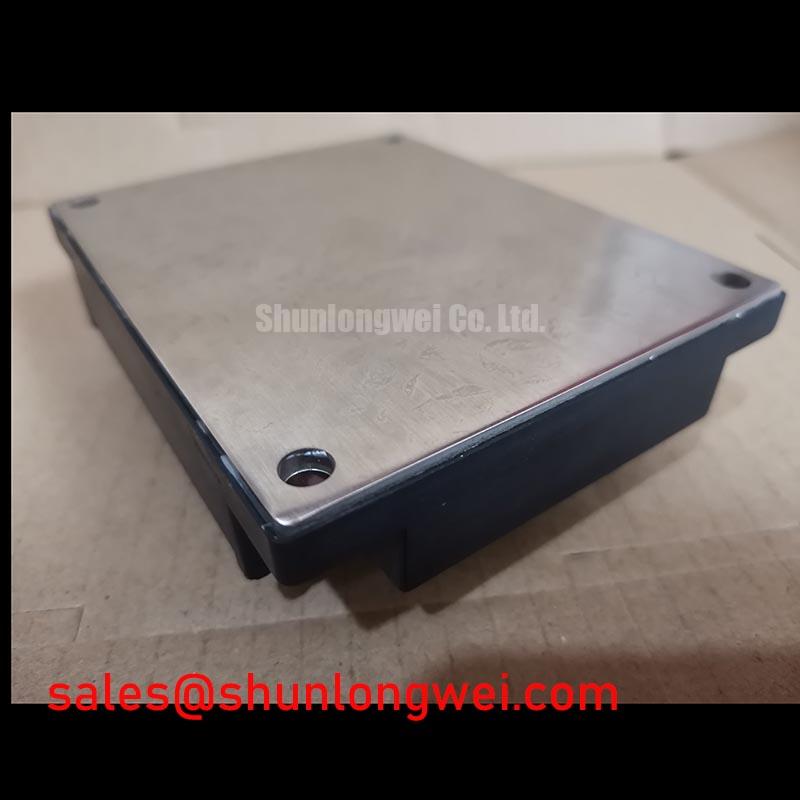

Fuji 7MBI75N-060 | A Robust, Integrated IGBT PIM for Reliable Power Conversion

The Fuji Electric 7MBI75N-060 is an established and highly reliable Power Integrated Module (PIM) designed for cost-sensitive and space-constrained power conversion applications. This module has earned its reputation as a workhorse component by delivering consistent performance and exceptional ruggedness, making it a strategic choice for engineers prioritizing long-term operational stability over cutting-edge switching frequencies.

Core Features at a Glance

- Integrated 7-in-1 Configuration: Combines a three-phase converter bridge, a three-phase inverter bridge, and a brake chopper with a freewheeling diode into a single, compact M-package.

- Proven NPT IGBT Technology: Utilizes Non-Punch-Through IGBTs, renowned for their wide Safe Operating Area (SOA) and superior short-circuit withstand capability.

- Optimized for Low-Frequency Operation: Engineered for exceptional performance in applications with PWM frequencies typically below 10 kHz, such as motor drives and uninterruptible power supplies.

- Simplified Thermal Management: The consolidated package design streamlines heat sink mounting and thermal design, reducing assembly complexity.

Key Technical Specifications

The following parameters define the operational envelope of the 7MBI75N-060, making it a dependable choice for a wide range of industrial power systems. For a comprehensive list of characteristics, you can download the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 600V |

| Continuous Collector Current (IC) @ TC=80°C | 75A (Inverter Part) |

| Collector-Emitter Saturation Voltage (VCE(sat)) typ. @ IC=75A | 2.2V |

| Total Power Dissipation (PC) per IGBT | 280W |

| Operating Junction Temperature (Tj) | +150°C |

| Short-Circuit Withstand Time (tsc) | ≥ 10µs |

Technical Deep Dive: Where Reliability Meets Integration

The enduring value of the Fuji 7MBI75N-060 lies in its fundamental design choices. Its Non-Punch-Through (NPT) silicon structure, while a more mature technology, provides an inherent robustness that is critical in harsh industrial environments. Unlike newer Trench/Field-Stop designs optimized for speed, NPT IGBTs exhibit a positive temperature coefficient for VCE(sat). This characteristic ensures natural current sharing when paralleling devices and provides a formidable defense against catastrophic failure during short-circuit events.

Furthermore, the 7-in-1 PIM topology is a masterclass in system-level engineering. By integrating the rectifier, brake, and inverter stages, it dramatically reduces component count, shrinks PCB footprint, and minimizes parasitic inductance associated with external wiring. For designers of compact Variable Frequency Drives (VFDs), this integration directly translates to lower manufacturing costs and improved electromagnetic compatibility (EMC) performance.

Optimized Application Scenarios

The 7MBI75N-060 excels where reliability and total cost of ownership are the primary design drivers. It is not intended to compete with the latest high-frequency SiC modules but rather to provide a steadfast solution for established applications.

- Small to Medium Motor Drives: It is an ideal power core for AC motor drives up to ~15 kW. Its integrated nature simplifies the design of drives for pumps, fans, conveyors, and other machinery where precise, high-speed control is secondary to durability.

- Uninterruptible Power Supplies (UPS): In online UPS systems, the integrated converter and inverter stages perfectly match the topology requirements, enabling the creation of compact and reliable power backup solutions.

- Welding Power Supplies: The module's inherent ruggedness and ability to handle pulsed loads make it a suitable candidate for the power stages in some inverter-based welding equipment. Understanding the potential causes of IGBT failure is key to designing such robust systems.

Frequently Asked Questions (FAQ)

Is the 7MBI75N-060 a good choice for new, high-efficiency designs?

For designs prioritizing the highest possible efficiency and power density, newer generation IGBTs or SiC modules may be more suitable. The 7MBI75N-060 is the strategic choice for applications where proven reliability, system simplicity, and cost-effectiveness are paramount. It is an excellent fit for upgrading existing designs or for new products in mature markets where a long service life is a key selling point.

What are the critical gate drive considerations for this module?

Given its NPT structure, a stable and robust gate drive is crucial. A dual-supply voltage of +15V for turn-on and a negative voltage (typically -5V to -15V) for turn-off is strongly recommended. The negative turn-off voltage ensures the gate is held firmly off, preventing parasitic turn-on due to dV/dt effects, which is fundamental for the reliability of all IGBT modules.