Fuji 7MBR50SD120 | High-Integration 7-in-1 PIM for Compact Power Conversion

Product Highlights: The Engineer's All-in-One Solution

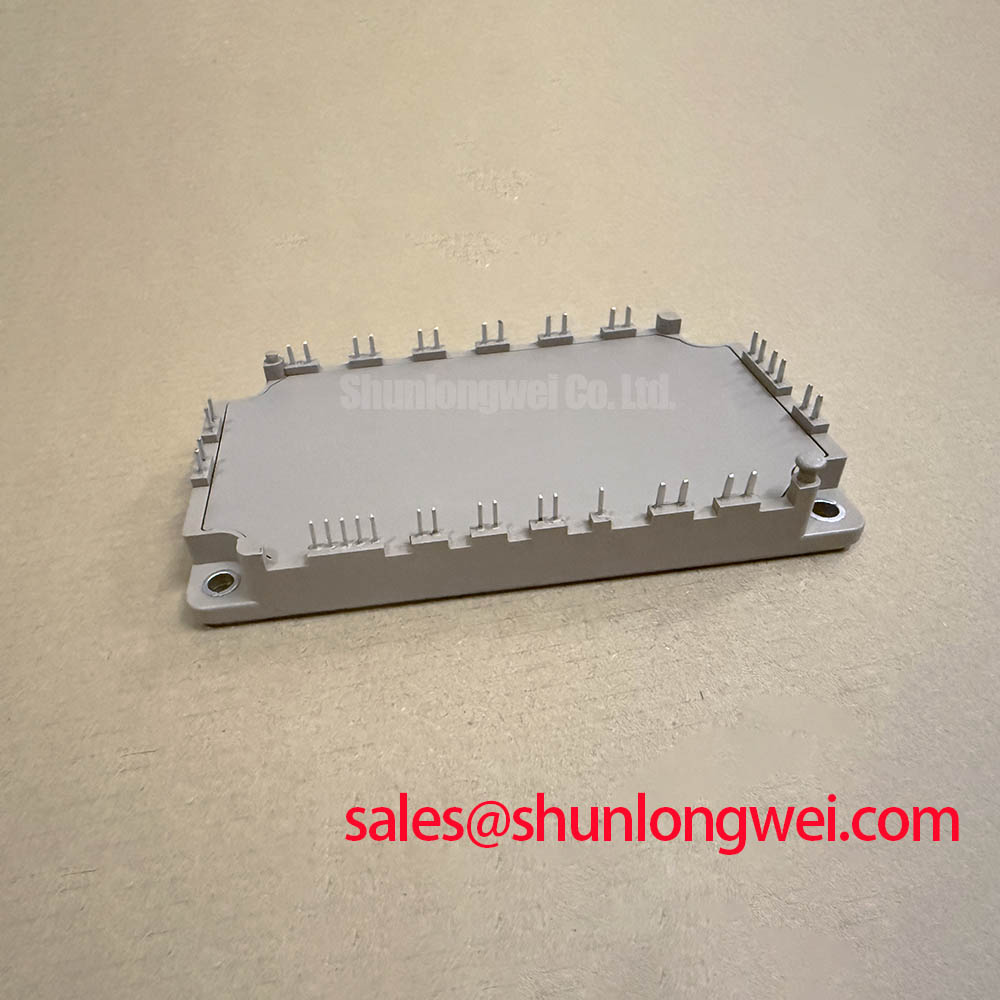

The Fuji 7MBR50SD120 is not just another IGBT module; it is a highly integrated Power Integrated Module (PIM) designed to streamline the development of compact and efficient power conversion systems. By combining a three-phase converter, a three-phase inverter, and a brake chopper into a single, thermally efficient package, it offers a significant advantage for engineers working on space-constrained applications. This module is engineered for reliability and performance in the demanding low-to-mid-power range.

- System Integration: Features a complete 7-in-1 topology (rectifier + inverter + brake), drastically reducing component count, simplifying PCB layout, and minimizing assembly complexity.

- Optimized Performance: Built with Fuji Electric's advanced trench gate and field-stop technology, ensuring a low VCE(sat) for reduced conduction losses and superior thermal efficiency.

- Enhanced Reliability: The integrated design minimizes parasitic inductance and provides a robust platform for reliable operation in industrial environments.

- Compact Footprint: Housed in a standard P610 package, it enables high power density, making it ideal for modern, compact drive designs.

Technical Deep Dive: Inside the 7MBR50SD120

The engineering excellence of the Fuji 7MBR50SD120 lies in its intelligent combination of silicon technology and package integration. The IGBTs utilize a trench gate structure, which allows for a higher channel density compared to older planar designs. This results in a significantly lower on-state voltage drop (VCE(sat)), directly translating to lower power dissipation and reduced heatsink requirements for the end application.

Furthermore, the module includes co-packaged Free-Wheeling Diodes (FWDs) that are performance-matched to the IGBTs. These diodes are engineered for soft and fast recovery characteristics, which is critical for minimizing turn-on losses (Eon) in the IGBT and reducing electromagnetic interference (EMI). This thoughtful pairing simplifies the design process, as engineers do not need to spend time selecting and qualifying external diodes, a common challenge when working with discrete solutions. The integrated NTC thermistor provides a direct, reliable method for monitoring junction temperature, enabling robust over-temperature protection schemes in the system controller.

Key Parameter Overview

For engineers requiring quick-reference data, the table below outlines the core electrical and thermal characteristics of the Fuji 7MBR50SD120. For a comprehensive list of specifications, please download the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200V |

| Collector Current (IC) @ TC=80°C | 50A (Inverter), 50A (Brake), 50A (Converter) |

| Collector-Emitter Saturation Voltage (VCE(sat)) Typ. | 1.7V (Inverter @ 50A) |

| Forward Voltage Diode (VF) Typ. | 1.6V (Inverter FWD @ 50A) |

| Package Type | P610 |

| Integrated NTC Thermistor | Yes |

Application Scenarios & Value Proposition

The integrated nature of the 7MBR50SD120 makes it an exceptional choice for a range of power conversion applications:

- Low-Power Variable Frequency Drives (VFD): For motor drives up to 15 kW, this PIM provides a complete power stage. Its high level of integration simplifies the Bill of Materials (BOM), reduces manufacturing costs, and accelerates time-to-market.

- Robotic and Servo Drives: The fast and soft-recovery FWDs ensure low-noise operation and precise current control, which are critical for the dynamic and high-precision performance required in modern robotics and CNC machinery.

- Uninterruptible Power Supplies (UPS): The module's compact footprint and high reliability are perfectly suited for small to medium-sized online UPS systems, where power density and dependable operation are paramount.

Frequently Asked Questions (FAQ)

What are the primary advantages of using a 7-in-1 PIM like the 7MBR50SD120 over a discrete component solution?The main benefits are system-level. A PIM drastically reduces parasitic inductance between components, leading to cleaner switching waveforms and lower voltage overshoots. It also simplifies thermal management by consolidating all major heat sources onto a single, optimized substrate. Finally, it significantly cuts down on assembly time and potential wiring errors, improving manufacturing yield and overall system reliability.

Is this module suitable for high-frequency applications like induction heating or welding?The Fuji 7MBR50SD120 is primarily optimized for motor control frequencies, typically operating below 15 kHz, where conduction losses are dominant. While it can function at higher frequencies, its switching losses will increase significantly. For applications like high-frequency induction heating or resonant power supplies, engineers should consider IGBTs specifically designed for low switching losses (Eoff). For a detailed evaluation for your specific application, please contact our technical team.