FANUC A76L-0300-0189 IGBT Module: Technical Data for Servo Drives

A Technical Introduction to the A76L-0300-0189

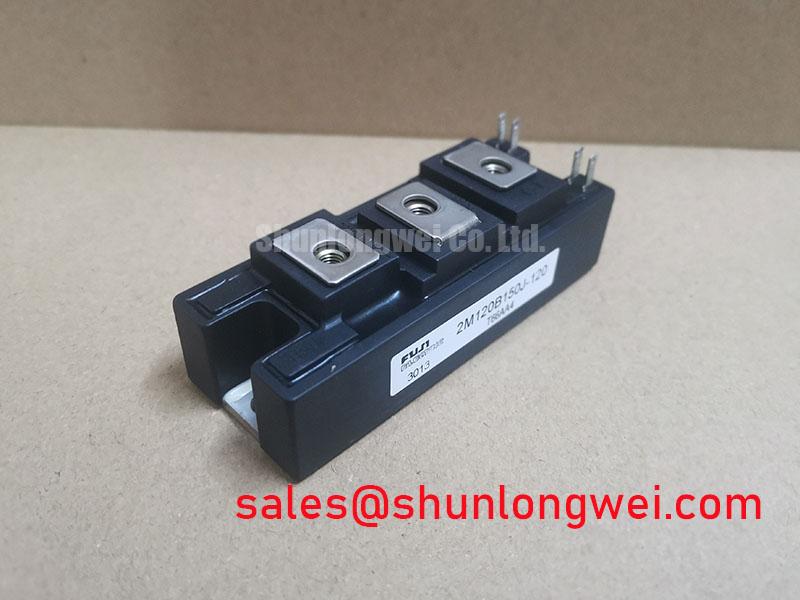

The FANUC A76L-0300-0189 is an Intelligent Power Module (IPM) that delivers a highly integrated power stage for controlling FANUC alpha series servo amplifiers. What is the primary function of the A76L-0300-0189? It provides a complete 7-in-1 power stage for motor control, consolidating a three-phase inverter bridge and brake chopper into a single, field-replaceable unit. This architecture is key to simplifying the design and maintenance of high-performance CNC machinery. This component is specifically designed for the demanding environment of industrial automation, where uptime and serviceability are paramount.

Data-Centric Evaluation: A76L-0300-0189 in Context

As a highly integrated component, the A76L-0300-0189 is the definitive OEM part for specific FANUC servo amplifiers. From a distributor's perspective, presenting factual data is key to enabling informed engineering and procurement decisions. Unlike general-purpose IGBTs, this module's value is defined by its precise fit within the FANUC ecosystem. An alternative might involve a complex redesign using discrete components, such as individual IGBTs and a dedicated gate driver like the SKHI 24 R, which would introduce significant engineering overhead, validation cycles, and would deviate from the original machine design, potentially impacting warranty and support. For maintenance and repair, adhering to the OEM-specified A76L-0300-0189 ensures that the servo drive's performance, protection mechanisms, and thermal behavior remain exactly as the manufacturer intended.

A76L-0300-0189 Core Specifications at a Glance

The technical parameters of the A76L-0300-0189 are tailored for its role within FANUC servo systems. Below are the core specifications that define its operational envelope.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 600V |

| Collector Current (Ic) - Inverter | 50A |

| Collector Current (Ic) - Brake | 50A |

| Configuration | 7-in-1 (3-Phase Inverter + Brake) |

| Manufacturer | FANUC |

Engineered for Integration: Core Application Value

The A76L-0300-0189 is fundamentally an application-specific power module, engineered for direct integration into FANUC's ecosystem of servo and spindle drives. Its primary role is to provide the high-power switching necessary for precise motor control in CNC machines, industrial robots, and other automated equipment. How does this IPM simplify maintenance? It enables fast replacement of the entire power section as one unit. The module's consolidated architecture provides several engineering advantages:

- Reduced Mean Time to Repair (MTTR): In a production environment, diagnosing and replacing a single module is significantly faster than troubleshooting a board with dozens of discrete power components, directly contributing to higher machine availability.

- Guaranteed Compatibility: As an original FANUC component, its electrical, thermal, and mechanical characteristics are perfectly matched to the servo amplifier's design, eliminating the risks associated with sourcing and validating third-party alternatives.

- Optimized Thermal Pathway: The module is designed to mount directly to the amplifier's heatsink, ensuring efficient heat dissipation critical for reliability under heavy-load machining operations.

For FANUC servo amplifiers requiring a 50A inverter stage, the A76L-0300-0189 is the specified component for ensuring OEM-level performance and maintainability. Its use is prevalent in systems that power the servo motors responsible for axis movement in a wide range of machine tools. For a deeper understanding of how these components fit into the bigger picture, exploring resources on IGBTs in robotic servo drives can provide valuable context.

Technical FAQ for the A76L-0300-0189 Module

Q1: What are common failure symptoms of the A76L-0300-0189 in a FANUC drive?

A: Failures in this IPM often manifest as specific alarms on the CNC control, such as over-current, short-circuit, or ground fault alarms. Physical symptoms can include a drive that fails to power up or immediate tripping upon attempting to enable the servo axis. A qualified technician can perform tests as detailed in guides on how to test an IGBT module to confirm an internal short.

Q2: Is the A76L-0300-0189 interchangeable with other FANUC IPMs?

A: No, part numbers in the FANUC ecosystem are highly specific. You must use the exact replacement part number specified for the servo amplifier model. Using an incorrect module, even one with similar voltage and current ratings, can lead to immediate failure or unsafe operation due to differences in pinout, control logic, and internal protection settings.

Q3: Why does this module use a 600V rating for a system typically running on a 400V-class AC line?

A: The 600V Collector-Emitter Voltage (Vces) provides a critical safety margin. A 400VAC line, when rectified, results in a DC bus voltage of approximately 565V. During motor deceleration, regenerative braking can cause this DC bus voltage to spike. The 600V rating ensures the IGBTs can withstand these transient overvoltage events, a crucial aspect for the longevity of any Servo Drive.

Q4: What is the main benefit of an IPM like the A76L-0300-0189 versus using discrete IGBTs?

A: The primary benefit is system simplification and reliability. This IPM integrates IGBTs, freewheeling diodes, and often the gate drive and protection circuits. This reduces PCB complexity, minimizes electromagnetic interference (EMI) by shortening power loops, and simplifies the thermal design. For a comprehensive comparison, see this guide on IPM vs. discrete IGBTs.

From Design to Field: Lifecycle Advantages

The adoption of the A76L-0300-0189 in FANUC's designs reflects a strategic decision favoring lifecycle value over initial component cost. For the original equipment designer, the IPM accelerates time-to-market by providing a pre-validated power core. For the end-user or maintenance engineer, it translates to a more robust and easily serviceable machine. The module effectively encapsulates the most complex and failure-prone part of the servo drive into a single, replaceable unit, turning a potentially lengthy board-level repair into a quick component swap.

Inside the Architecture: A Consolidated Power Stage

At its core, the A76L-0300-0189 is an example of advanced power packaging. The module integrates seven IGBTs and their corresponding freewheeling diodes. Six of these form a standard three-phase bridge for driving the three windings of a servo motor. The seventh IGBT is dedicated to the dynamic brake circuit, which dissipates regenerative energy from the motor into a braking resistor during rapid deceleration. The module's collector current (Ic) rating of 50A can be visualized like a highway's vehicle capacity; it defines the maximum continuous current the device can handle without overheating, directly correlating to the torque output of the connected motor.

The Strategic Role of IPMs in Modern Automation

The trend in industrial automation is toward more compact, energy-efficient, and reliable systems. Intelligent Power Modules (IPMs) like the A76L-0300-0189 are central to this evolution. By abstracting the complexity of the power electronics, they allow machine builders to focus on their core competencies—motion control algorithms, software, and mechanical design. This modular approach not only enhances the reliability of the final product but also builds a more efficient global service and support network, as standardized components simplify logistics and technician training.

Moving forward, the integration seen in this FANUC module sets a benchmark. As automation systems demand higher power densities and greater intelligence, the role of pre-integrated, application-specific modules will only expand, becoming the foundational building blocks for the next generation of robotics and CNC machinery.