Content last revised on December 29, 2025

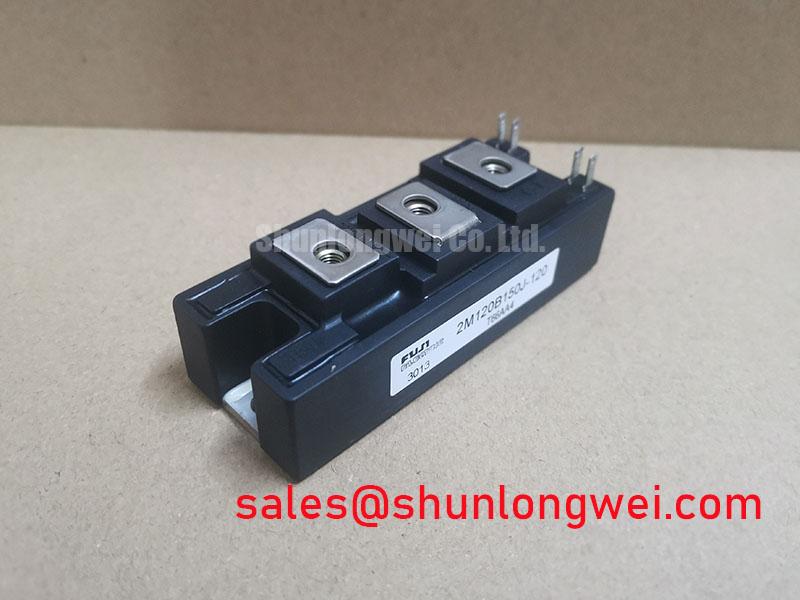

2M120B150J-120 IGBT Module: Engineering for High-Efficiency Power Conversion

Product Overview

Optimized for Reduced Losses and Higher Power Density

The 2M120B150J-120 is a 1200V dual IGBT module engineered for superior switching efficiency, enabling designers to achieve higher power density and reduced thermal overhead in high-frequency power conversion systems. This module integrates two IGBTs in a half-bridge configuration, offering core specifications of 1200V | 150A | VCE(sat) 2.1V (typ). Its key engineering benefits include significantly reduced thermal load and the capability to design more compact systems. For engineers developing next-generation inverters or power supplies, the 2M120B150J-120 provides the performance characteristics necessary for fast-switching topologies without compromising reliability. Best fit for high-frequency motor drives and solar inverters where minimizing switching losses is a primary design objective.

Key Parameter Overview

Decoding the Specs for High-Frequency Performance

The technical specifications of the 2M120B150J-120 are tailored for applications demanding a precise balance between low on-state losses and fast, clean switching. The low typical VCE(sat) value is a critical parameter that directly correlates to lower conduction losses, while the switching energy values (Eon, Eoff) are indicative of its performance at higher frequencies. This data-driven design enables engineers to accurately model thermal performance and efficiency from the outset.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Collector-Emitter Voltage | Vces | 1200V | Tj = 25°C |

| Continuous Collector Current | Ic | 150A | Tc = 80°C |

| Collector-Emitter Saturation Voltage | VCE(sat) | 2.1V (typ) | Ic = 150A, Vge = 15V, Tj = 125°C |

| Total Power Dissipation | Pc | 780W | Tc = 25°C per IGBT |

| Turn-On Switching Energy | Eon | 16.5 mJ (typ) | Ic = 150A, Vcc = 600V, Tj = 125°C |

| Turn-Off Switching Energy | Eoff | 18.0 mJ (typ) | Ic = 150A, Vcc = 600V, Tj = 125°C |

| Thermal Resistance, Junction to Case | Rth(j-c) | 0.16 °C/W | Per IGBT |

Application Scenarios & Value

System-Level Benefits in Demanding Power Conversion Topologies

The 2M120B150J-120 is engineered for direct integration into high-performance power electronics where efficiency and reliability are paramount. Its primary value is realized in applications that leverage its fast and low-loss switching characteristics.

- Variable Frequency Drives (VFDs): In a modern VFD, minimizing heat dissipation is critical for achieving a compact design. The low VCE(sat) of the 2M120B150J-120 reduces conduction losses, which are dominant at lower motor speeds. As the switching frequency increases to improve motor control dynamics, its low Eon and Eoff energies become crucial for managing switching losses. This dual benefit allows for smaller heatsinks and a more power-dense inverter design, directly contributing to a lower overall system cost and footprint.

- Solar Inverters: Maximizing energy harvest requires the highest possible conversion efficiency. The module's fast and soft-recovery freewheeling diode (FWD) minimizes reverse recovery losses, a significant factor in the overall efficiency of DC/AC inverters. This allows the system to operate closer to its Maximum Power Point Tracking (MPPT) algorithm's ideal, increasing the kilowatt-hours delivered to the grid.

- Uninterruptible Power Supplies (UPS): In online UPS systems, efficiency directly impacts operating costs and battery backup time. The low total losses of this module ensure that less energy is wasted as heat, both in normal operation and during battery discharge, enhancing system reliability and reducing cooling requirements.

This module provides a robust solution for power stages up to approximately 50kW. For systems requiring higher current handling, the related 2MBI200NB-120 offers a continuous current rating of 200A within a similar voltage class.

Technical Deep Dive

An Analysis of Conduction and Switching Losses

A granular analysis of the 2M120B150J-120's electrical characteristics reveals a design focus on minimizing the two primary sources of loss in an IGBT: conduction and switching. The Collector-Emitter Saturation Voltage, or VCE(sat) , is the key determinant of conduction loss. With a typical value of 2.1V at its nominal current, this module presents a low-resistance path when fully turned on. Think of VCE(sat) as a measure of friction; a lower value is akin to water flowing through a wider, smoother pipe, generating less heat (I²R loss) for the same amount of current flow. This directly translates to higher efficiency, especially in applications with long on-state durations, such as the output stage of a motor drive operating at low speeds.

Conversely, Switching Loss becomes the dominant factor as operational frequencies increase. The 2M120B150J-120's low turn-on (Eon) and turn-off (Eoff) energy values signify that the transition between the on and off states is both rapid and efficient. Each transition consumes a small packet of energy, and at tens of kilohertz, these packets add up to significant power loss. By minimizing the energy in each packet, the module enables designers to push frequencies higher—to shrink magnetic components and improve control response—without incurring a prohibitive thermal penalty.

Industry Insights & Strategic Advantage

Meeting Tomorrow's Efficiency Standards in Industrial Automation

The deployment of the 2M120B150J-120 aligns with key strategic trends in industrial automation and renewable energy. Global regulations and market demand are relentlessly pushing for higher energy efficiency in systems like VFDs and servo drives, as outlined by efficiency classes such as IE3 and IE4 for electric motors. The core of meeting these standards lies within the power conversion stage. A module with low total losses, like the 2M120B150J-120, becomes an enabling component, not just a passive part. It allows system designers to meet or exceed these stringent requirements, providing a competitive advantage and ensuring compliance with evolving energy directives.

Furthermore, the trend towards decentralization and miniaturization in factory automation places a premium on power density. By facilitating the use of smaller heatsinks and magnetics, this IGBT module directly supports the development of more compact, integrated drive solutions that can be placed closer to the motor, reducing cabling costs and improving EMC performance in line with standards like IEC 61800-3. Adopting this module is a strategic decision to build systems that are not only efficient today but are also architected for the demands of tomorrow's automated environments.

Frequently Asked Questions

Design Considerations for Maximizing Efficiency and Reliability

How does the VCE(sat) of 2.1V impact thermal design compared to an older generation IGBT with a VCE(sat) of 2.5V?

At 150A, the 0.4V reduction in VCE(sat) translates to a 60W (0.4V * 150A) decrease in conduction losses per switch. In a half-bridge configuration, this significantly reduces the total heat generated, potentially allowing for a smaller, lower-cost heatsink or providing a greater thermal margin for operation in high ambient temperatures, thereby enhancing overall system reliability.

What is the primary benefit of the integrated soft-recovery freewheeling diode (FWD)?

The soft-recovery characteristic of the FWD minimizes voltage overshoot and ringing during turn-off. This reduces electromagnetic interference (EMI) and lessens the voltage stress on the IGBT, often simplifying the design and cost of the required snubber circuit and improving the device's resilience under hard-switching conditions.

Is this module suitable for paralleling to achieve higher current output?

Yes, IGBT modules like the 2M120B150J-120 can be paralleled. However, successful implementation requires careful attention to gate drive symmetry, busbar layout to ensure balanced current sharing, and thermal management. For a comprehensive guide, refer to resources on IGBT Paralleling .

How do I interpret the switching energy (Eon/Eoff) values for my specific application?

The datasheet values for Eon and Eoff are provided under specific test conditions (Vcc, Ic, Tj, Rg). To estimate switching losses in your application, these values must be scaled according to your actual operating voltage and current. The total switching power loss is calculated as P_sw = (Eon + Eoff) * f_sw, where f_sw is your switching frequency. For a deeper understanding, review our guide on how to decode IGBT datasheets.

Strategic Integration

Integrating the 2M120B150J-120 is a forward-looking choice for engineering teams focused on lifecycle performance and market competitiveness. Its foundation of low-loss operation provides a direct path to achieving higher system efficiency ratings and greater power density. This allows for the design of more compact, reliable, and cost-effective power conversion systems that are well-positioned to meet the escalating demands for energy conservation and performance in the industrial and renewable energy sectors.