Content last revised on December 11, 2025

A Technical Analysis of the BSM300GB60DLC for High-Efficiency Power Conversion

Introduction: Driving Efficiency in Power Systems

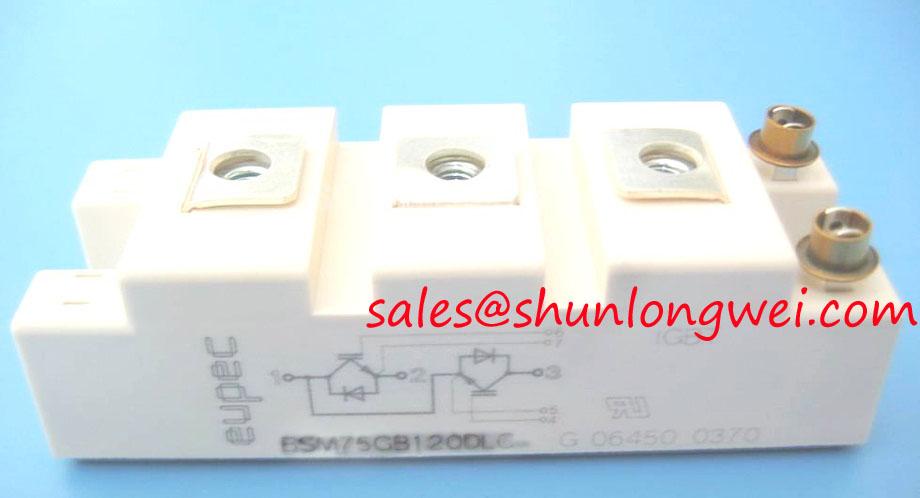

The Infineon BSM300GB60DLC is a high-performance dual IGBT module engineered to deliver superior efficiency in demanding power conversion applications. By integrating advanced technology into a robust industrial package, it provides a crucial building block for modern power electronics. Key specifications include 600V blocking voltage, 300A nominal collector current, and an exceptionally low typical collector-emitter saturation voltage (VCE(sat)) of 1.95V. This translates directly into two primary engineering benefits: significantly reduced conduction losses and simplified thermal design. For engineers wondering how to improve the efficiency of a motor drive or UPS, the BSM300GB60DLC's low on-state voltage directly reduces the power dissipated as heat during operation. For motor drives and UPS systems up to ~150 kW requiring minimal conduction losses, this 600V module delivers an optimal balance of performance and thermal efficiency.

Application Scenarios & Value

Achieving System-Level Benefits in High-Frequency Power Conversion

The BSM300GB60DLC is engineered for applications where thermal performance and efficiency are paramount. For a design engineer developing a compact and powerful Variable Frequency Drive (VFD), the primary challenge is often managing heat dissipation within a constrained enclosure. The module's low VCE(sat) of 1.95V at its nominal current is a decisive factor, as it directly minimizes conduction losses—the primary source of heat in the IGBT at medium operating frequencies. This allows for the use of smaller, more cost-effective heatsinks and can even increase the overall power density of the final system. What is the primary benefit of its low on-state voltage? It enhances system reliability by lowering the operating junction temperature. Its robust construction and dual (half-bridge) configuration make it an excellent choice for three-phase inverters used in industrial motor control, high-capacity uninterruptible power supplies (UPS), and welding equipment. While the BSM300GB60DLC is optimized for 600V systems, for applications demanding higher blocking voltage, the related BSM200GB120DN2 offers a 1200V rating.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The performance of the BSM300GB60DLC is defined by a set of critical parameters that directly influence its behavior in a power circuit. The values below are based on the official datasheet and provide a clear view of its capabilities for system design and simulation. Understanding these figures is the first step in leveraging the module's full potential for efficiency and reliability.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | 600V | - |

| Continuous DC Collector Current | IC | 300A | Tc = 65°C |

| Collector-Emitter Saturation Voltage | VCE(sat) | 1.95V (typ.), 2.45V (max.) | IC = 300A, VGE = 15V, Tvj = 25°C |

| Gate-Emitter Peak Voltage | VGES | +/- 20V | - |

| Total Power Dissipation | Ptot | 1250W | Tc = 25°C |

| Isolation Test Voltage | VISOL | 2.5 kV | RMS, f=50Hz, t=1min |

Sourced from the official Eupec/Infineon datasheet.

Download the BSM300GB60DLC datasheet for detailed specifications and performance curves.

Technical Deep Dive

Analyzing the Impact of IGBT Technology on Conduction Losses

A key factor behind the BSM300GB60DLC's efficiency is its underlying IGBT technology. While the specific generation isn't explicitly named as "TrenchSTOP™" in older datasheets, its performance characteristics are indicative of advanced trench-gate structures pioneered by Infineon. This design significantly lowers the on-state resistance compared to older planar IGBTs. To visualize this, imagine water flowing through pipes. A planar IGBT is like a series of narrow pipes, creating significant resistance. A trench-gate IGBT, however, is like a single, wide channel, allowing a much higher volume of current to pass with less resistance. This "wider channel" directly results in a lower voltage drop across the device—the VCE(sat). A lower VCE(sat) means less energy is converted into waste heat, a critical advantage for improving the efficiency and reliability of a high-power inverter. What is the engineering trade-off? This architecture is optimized to strike a precise balance between conduction losses and switching losses, making it ideal for applications operating in the 5-20 kHz range, such as industrial motor drives.

Frequently Asked Questions (FAQ)

What is the significance of the 1.95V typical VCE(sat) for thermal design?

A lower VCE(sat) directly reduces conduction power loss (P_cond = VCE(sat) * IC). With less power being dissipated as heat, designers can specify a smaller, lighter, and more cost-effective heatsink to maintain the junction temperature within safe limits. This improves the overall power density and can lower the total system cost.

How does the dual-switch half-bridge configuration of the BSM300GB60DLC benefit system design?

The half-bridge (or "dual") configuration integrates two IGBTs and two freewheeling diodes into a single module, forming the fundamental building block for one phase of a three-phase inverter. This simplifies the PCB layout, reduces stray inductance compared to using discrete components, and streamlines the assembly process for applications like Variable Frequency Drives (VFDs) and UPS systems.

Strategic Design Considerations

Incorporating the BSM300GB60DLC into a power system is a strategic decision that extends beyond its core electrical specifications. Its low-loss profile enables designers to meet increasingly stringent energy efficiency standards, such as those for industrial motors and power supplies. By minimizing wasted energy, systems built with this module not only reduce operational electricity costs but also enhance long-term reliability through lower thermal stress. This positions the BSM300GB60DLC as a key enabler for developing more sustainable and economically advantageous power electronic systems.