Content last revised on January 11, 2026

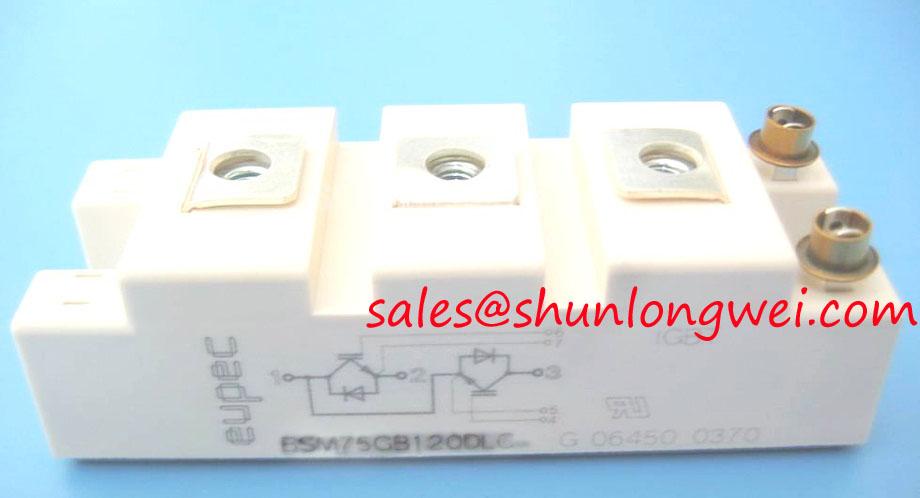

Infineon BSM75GB120DLC IGBT Module | The Integrated Power Solution for Demanding Motor Drives

The Infineon BSM75GB120DLC is a highly reliable and efficient 1200V, 75A Power Integrated Module (PIM) designed to streamline the development of compact power conversion systems. By integrating a three-phase inverter bridge with a brake chopper into a single industry-standard package, this IGBT Module offers a robust and cost-effective solution for industrial automation, particularly in motor and servo drives.

Technical Deep Dive: The Engineering Behind the BSM75GB120DLC

From an engineering perspective, the value of the BSM75GB120DLC is rooted in its intelligent integration and optimized semiconductor technology. This isn't just about combining components; it's about enhancing system performance.

- Integrated CIB (Converter-Inverter-Brake) Topology: The module incorporates a full three-phase inverter bridge (six IGBTs and six diodes) alongside a dedicated brake chopper IGBT and its freewheeling diode. This single-package solution eliminates the need for an external brake unit, drastically simplifying PCB layout, reducing assembly time, and minimizing stray inductance between the inverter and braking circuits. The direct result for designers is a smaller system footprint and improved electrical performance.

- Low Conduction Loss (Vce(sat)) IGBTs: The "L" in the "DLC" suffix denotes its low VCE(sat) characteristics. This means less power is wasted as heat during the on-state, which is the dominant loss factor in motor drive applications that typically operate at lower switching frequencies. This translates directly to higher system efficiency, reduced heatsink requirements, and lower operating temperatures, contributing to a longer service life.

Application Scenarios: Where Integration Delivers Tangible Value

The design of the Infineon BSM75GB120DLC makes it a workhorse for a variety of power conversion applications, solving specific industry pain points.

- Variable Frequency Drives (VFDs): In applications like cranes, elevators, and conveyors, managing regenerative energy is critical for safety and control. The integrated brake chopper provides a seamless, built-in solution to dissipate this energy, preventing DC bus overvoltage without the complexity and cost of a separate braking module.

- High-Performance Servo Drives: The module's robust design and fast, soft-recovery freewheeling diodes ensure precise and reliable current control. This is essential for powering precision robotic servo drives where accurate positioning and dynamic response are non-negotiable.

- Uninterruptible Power Supplies (UPS): For mission-critical infrastructure, reliability is paramount. The proven durability and thermal stability of the BSM75GB120DLC provide a solid foundation for the inverter stage, ensuring dependable power delivery when it's needed most.

- General Industrial Automation: As a versatile power block, it serves as an excellent core for custom-built inverters, welding equipment, and other systems requiring a three-phase output with braking capability.

Key Technical Parameters

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Continuous Collector Current (Ic) @ 80°C | 75 A |

| Collector-Emitter Saturation Voltage (Vce(sat)) typ. @ 75A | 2.15 V |

| Package Type | Industry Standard PIM / CIB Module |

For a comprehensive overview of all electrical and thermal characteristics, please refer to the official BSM75GB120DLC Datasheet.

Selection Advice: Integrated PIM vs. Standard Six-Pack

When choosing an IGBT module, a key decision is between an integrated PIM like the BSM75GB120DLC and a standard six-pack module without a brake chopper.

- Choose the BSM75GB120DLC if: Your application requires regenerative braking, and you prioritize a compact design, simplified assembly, and reduced system cost. It is the ideal all-in-one solution for most standard motor drives.

- Consider a separate Six-Pack + Brake Unit if: Your application involves extremely high-duty-cycle braking where thermal management for the brake chopper needs to be isolated from the main inverter. For applications demanding much higher switching frequencies (above 15-20 kHz), you might explore newer technologies like Infineon TRENCHSTOP™ IGBT3 or higher, which are optimized for lower switching losses.

Frequently Asked Questions (FAQ)

- How does the integrated brake chopper impact thermal design?

When designing the heatsink, you must account for the combined power losses from both the inverter section and the brake chopper section. The datasheet provides the necessary thermal resistance values to calculate the total heat dissipation under your specific load and braking profiles. - Is this module suitable for paralleling to achieve higher current?

While possible, paralleling PIM modules is complex due to the integrated nature. If your current requirements exceed 75A, it is generally recommended to select a single, higher-rated IGBT module to ensure better current sharing and thermal balance. For an in-depth understanding, see our guide on the fundamentals of IGBT modules.

For applications demanding a compact, reliable, and cost-effective power stage, the Infineon BSM75GB120DLC remains a top-tier choice. If you are unsure whether this integrated approach is the optimal fit for your specific design challenges, please contact our engineering team for a detailed consultation and expert guidance.