Content last revised on January 26, 2026

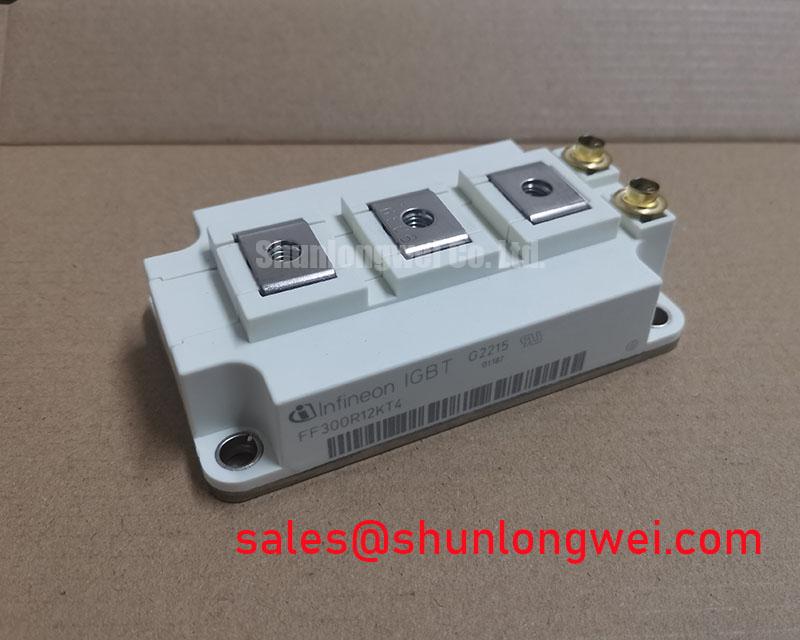

FF300R12KT4: A Technical Guide to Infineon's 1200V, 300A Dual IGBT Module

Introduction to a Workhorse Power Module

Optimizing Performance in High-Frequency Industrial Drives

The Infineon FF300R12KT4 is a 1200V, 300A dual IGBT module engineered for high-reliability power conversion systems. This module integrates fast TRENCHSTOP™ IGBT4 technology with an optimized Emitter Controlled diode, delivering a robust solution for demanding applications. Key specifications include: 1200V Collector-Emitter Voltage | 300A Continuous Collector Current | Tvj op of 150°C. This combination provides tangible benefits such as reduced switching losses and superior thermal performance. For engineers designing high-frequency motor drives or inverters, the FF300R12KT4 addresses the critical need for efficient power handling in a standard 62mm industrial package. What is the primary benefit of its TRENCHSTOP™ IGBT4 technology? It enables lower saturation voltage and reduced switching losses, leading to higher system efficiency. For high-frequency industrial drives requiring a balance of robust performance and efficiency, this 1200V module presents a well-engineered solution.

Application Scenarios & Value

Achieving System-Level Benefits in Demanding Power Conversion

The FF300R12KT4 is engineered to solve specific challenges in high-power electronics. Its primary value lies in its ability to enhance the efficiency and reliability of systems operating under demanding load cycles. A prime application is in industrial Variable Frequency Drives (VFDs), which control the speed of AC motors in machinery like conveyors, pumps, and fans. In these systems, the IGBTs are subjected to continuous high-frequency switching. The FF300R12KT4's low collector-emitter saturation voltage (VCE(sat)) of 1.75V (typical at nominal current) directly reduces conduction losses. This is analogous to reducing friction in a mechanical system; less energy is wasted as heat, which in turn simplifies the thermal design and can lower the total cost of ownership. The module also finds application in solar inverters and Uninterruptible Power Supplies (UPS), where maximizing energy throughput and ensuring long-term operational stability are paramount. For systems requiring a higher current rating within a similar package, the FF400R12KT4 offers an increased capacity.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the FF300R12KT4 are foundational to its performance in real-world applications. The following table highlights the critical parameters that design engineers should focus on for system integration and performance modeling.

| Parameter | Value | Conditions | Engineering Implication |

| Collector-Emitter Voltage (VCES) | 1200 V | Tvj = 25°C | Provides a substantial safety margin for applications on 400V to 575V AC lines, ensuring robustness against voltage transients. |

| Continuous Collector Current (IC nom) | 300 A | TC = 100°C, Tvj max = 175°C | Defines the nominal current handling capability, critical for sizing the module for specific motor power ratings or inverter output. |

| Collector-Emitter Saturation Voltage (VCEsat) | 1.75 V (typ) | IC = 300 A, VGE = 15 V, Tvj = 25°C | A lower VCEsat directly translates to lower conduction losses, reducing heat generation and improving overall inverter efficiency. |

| Total Switching Energy (Ets) | 37 mJ (typ) | IC = 300 A, VCE = 600V, VGE = ±15V, RG = 3.3 Ω, Tvj = 125°C | This value is crucial for calculating thermal load at high switching frequencies; lower energy loss per cycle enables higher frequency operation or reduced cooling requirements. |

| Thermal Resistance, Junction to Case (RthJC) | ≤0.075 K/W per IGBT | Indicates the efficiency of heat transfer from the semiconductor chip to the module's baseplate. A low RthJC is vital for effective cooling and long-term reliability. | |

| Short Circuit Withstand Time (tSC) | ≤10 µs | VGE ≤ 15V, VCC ≤ 800V, Tvj ≤ 150°C | Defines the module's ability to survive a short-circuit event, a critical safety parameter for protecting the drive and the motor. |

Download the FF300R12KT4 datasheet for detailed specifications and performance curves.

Frequently Asked Questions (FAQ)

How does the thermal resistance (RthJC) of 0.075 K/W impact heatsink selection and system power density?

A low RthJC signifies efficient heat transfer from the IGBT chip to the case. This allows for the use of a smaller, more cost-effective heatsink for a given power dissipation. It's like having better insulation on a house; you need a less powerful (and cheaper) air conditioner. This directly enables designers to achieve higher power density, packing more performance into a smaller enclosure.

What is the significance of the TRENCHSTOP™ IGBT4 technology in the FF300R12KT4?

Infineon's TRENCHSTOP™ IGBT4 technology is a trench-gate, field-stop design that optimizes the trade-off between conduction losses (VCEsat) and switching losses (Ets). It allows the device to achieve a low "on-state" voltage drop while still being able to switch off quickly, which is critical for reducing energy waste in high-frequency applications like motor drives and solar inverters.

Can the FF300R12KT4 be used in parallel to achieve higher output currents?

Yes, IGBT modules like the FF300R12KT4 can be connected in parallel. However, successful paralleling requires careful design considerations. The positive temperature coefficient of VCEsat in these modules provides a degree of self-balancing. Still, designers must ensure symmetrical busbar layouts and use individual gate resistors to prevent oscillations and ensure balanced current sharing during switching transients. For a deeper understanding, explore resources on IGBT Paralleling.

What does the maximum operating junction temperature (Tvj op) of 150°C imply for system design?

The 150°C operating temperature provides significant headroom for designs operating in harsh industrial environments. It allows the module to function reliably at high ambient temperatures or under heavy load conditions without immediate derating, enhancing the overall robustness of the end system.

An Engineer's Perspective

From an engineering standpoint, the FF300R12KT4 represents a mature and reliable building block for power conversion. Its standardized 62mm package simplifies mechanical integration, while the well-documented electrical and thermal characteristics allow for accurate system modeling and performance prediction. The key is leveraging its balanced loss characteristics to optimize the system for either maximum efficiency at a given frequency or for higher switching frequencies to reduce the size of magnetic components. The module's robustness, evidenced by its short-circuit withstand time and high operating temperature, provides the necessary design margin for creating durable and reliable industrial equipment. For engineers developing next-generation motor control or power supply systems, this module offers a proven foundation upon which to build.