Content last revised on January 25, 2026

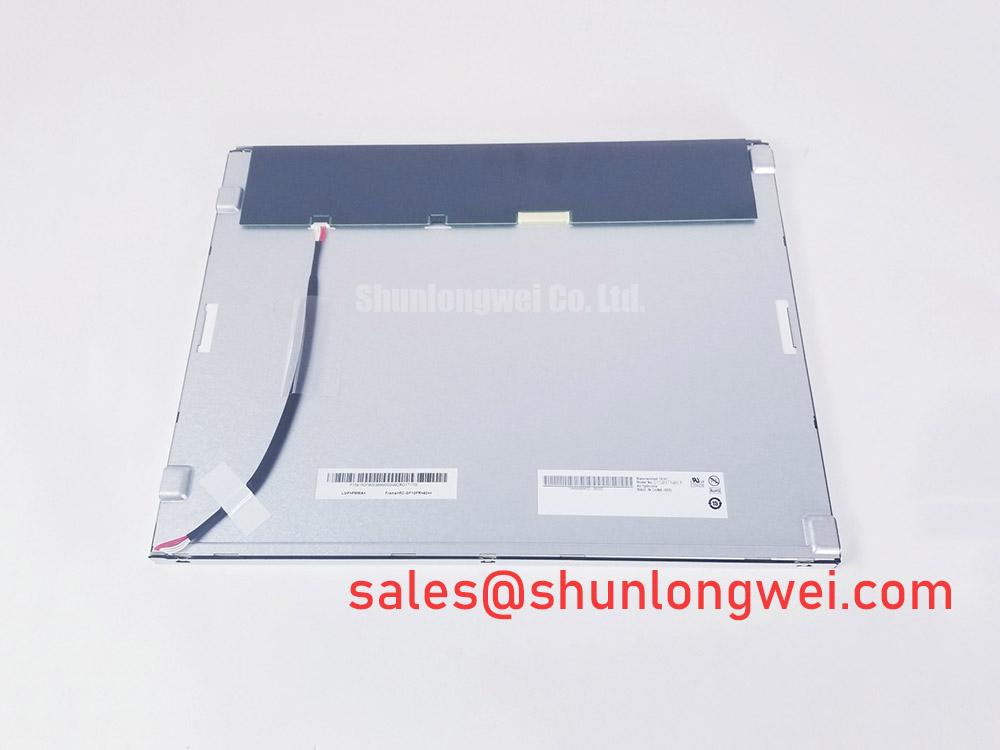

AUO G150XTN06.0: Engineering a 15-inch XGA Display for Industrial Longevity and Performance

Key Parameter Overview

Decoding the Specs for Industrial Environments

The AUO G150XTN06.0 is an a-Si TFT-LCD module engineered specifically for demanding industrial applications. Its performance is defined by a combination of visual quality, operational robustness, and long-term reliability. The specification sheet reveals a display designed not just for image reproduction, but for sustained performance in challenging conditions. The panel's high brightness and wide operating temperature range are critical for ensuring readability and functionality in factory automation, HMIs, and outdoor kiosks. The long-life WLED backlight system is a cornerstone of its design, directly addressing the total cost of ownership by extending operational uptime and reducing maintenance cycles.

Central to its value is the extremely wide operating temperature range of -30°C to 85°C, ensuring consistent performance in unconditioned environments, from cold storage facilities to sun-exposed control panels. This thermal resilience, combined with a 70,000-hour WLED backlight lifespan, makes it a fit-and-forget component for long-lifecycle industrial equipment. For applications in process control or outdoor terminals where consistent readability is non-negotiable, the G150XTN06.0 is an optimal choice.

| Specification | Value | Engineering Implication |

|---|---|---|

| Screen Size | 15.0 inch | Provides a substantial viewing area suitable for complex data visualization in industrial HMIs and control systems. |

| Resolution | 1024 x 768 (XGA) | Delivers clear, sharp imagery required for detailed schematics, process monitoring, and graphical user interfaces. |

| Brightness | 450 cd/m² (Typ.) | Ensures excellent screen readability in high ambient light conditions, a common challenge in factory floors and outdoor settings. |

| Operating Temperature | -30°C to 85°C | Guarantees operational reliability across extreme thermal environments, eliminating the need for auxiliary heating or cooling systems. |

| Backlight Lifetime | 70,000 hours (Typ.) | Significantly reduces maintenance requirements and lowers total cost of ownership, crucial for embedded and critical systems. |

| Viewing Angle (L/R/U/D) | 80°/80°/70°/80° (Typ.) | Offers wide, consistent viewing angles, allowing operators to view the screen clearly from various off-axis positions. |

| Interface | LVDS (1 ch, 6/8-bit) | A standard, robust interface that simplifies system integration and ensures reliable data transmission in electrically noisy environments. |

Download the G150XTN06.0 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Demanding HMI and Control Applications

The G150XTN06.0 is engineered for environments where standard commercial displays falter. Its primary value is realized in applications requiring high reliability and consistent visual performance under fluctuating environmental conditions. Consider a CNC machine controller on a factory floor. The operator needs to clearly read machining coordinates and status updates amidst bright, shifting overhead lights and potential temperature swings. The G150XTN06.0's 450-nit brightness and anti-glare surface treatment directly address this challenge, ensuring legibility and reducing operator eye strain. What is the primary benefit of its wide temperature range? It ensures operational integrity without additional thermal management hardware. This simplifies the mechanical design of the HMI enclosure, reduces system cost, and eliminates a potential point of failure.

Its robust design extends to marine bridge displays and agricultural vehicle cabins, where constant vibration and exposure to extreme temperatures are the norm. The panel's ability to operate flawlessly from -30°C to 85°C is a critical design enabler for these systems. While this model provides an excellent balance of features for many industrial uses, for systems that may benefit from the wider color gamut and viewing angles of IPS technology, the related G150XNE-L01 presents an alternative for consideration.

Frequently Asked Questions

How does the 70,000-hour backlight lifetime translate to real-world system reliability?

A 70,000-hour backlight lifetime, equivalent to nearly 8 years of continuous 24/7 operation, is a critical factor in minimizing the total cost of ownership. For industrial equipment with long service life expectations, such as in factory automation or critical infrastructure monitoring, this extended lifespan means fewer maintenance cycles, reduced downtime, and greater system availability. It allows engineers to design systems with the confidence that the display will not be the primary point of failure.

What is the significance of the -30°C to 85°C operating temperature range for system design?

This wide thermal operating window is a significant engineering advantage. It allows the G150XTN06.0 to be deployed in sealed, fanless enclosures and in outdoor or un-climatized environments without requiring external heating or cooling components. This not only simplifies the mechanical and thermal design of the final product but also enhances its overall reliability by reducing the number of moving parts that can fail. For applications like outdoor ticketing machines or control panels in refrigerated logistics, this feature is indispensable.

Is the LVDS interface on the G150XTN06.0 suitable for high EMI environments?

Yes, the LVDS Interface (Low-Voltage Differential Signaling) is inherently robust against electromagnetic interference (EMI). Its differential nature means that noise tends to be coupled equally onto both signal lines, where it is rejected by the receiver. This makes it a highly reliable choice for the electrically noisy environments typical of industrial settings, where motors, drives, and welding equipment can be in close proximity to the HMI or control panel. This ensures signal integrity and a stable, flicker-free display.

From an engineering standpoint, the G150XTN06.0 from AUO is a component that prioritizes operational resilience. Its specifications are not just numbers on a page; they are deliberate design choices that directly translate into a more robust, reliable, and cost-effective end product for the system integrator.