Content last revised on January 12, 2026

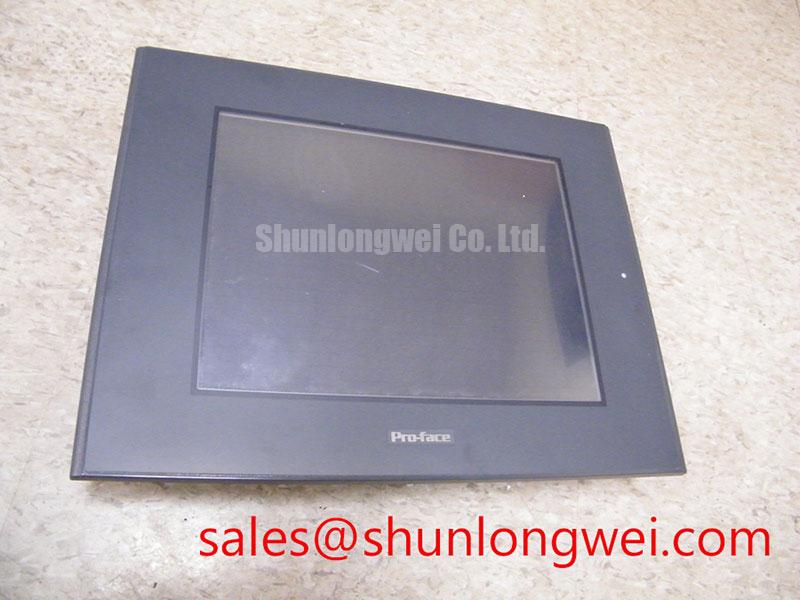

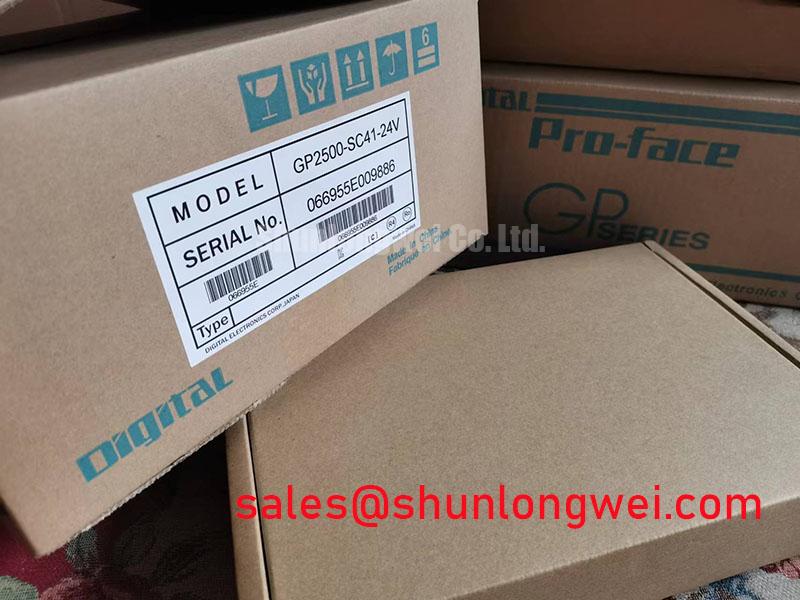

Pro-face GP2500-SC41-24V | The Definitive Engineer's HMI for Unmatched Reliability

For engineering professionals managing critical industrial infrastructure, the true measure of a Human-Machine Interface (HMI) isn't just its feature set, but its unwavering reliability over years of relentless operation. The Pro-face GP2500-SC41-24V is an embodiment of this principle—a field-proven workhorse designed for longevity, stability, and seamless integration into demanding factory environments.

Application Scenarios & Engineering Value

The strategic value of the GP2500-SC41-24V lies in its focused design, making it an optimal choice for specific industrial contexts where reliability trumps novelty. From a system integrator's perspective, this HMI excels in:

- Legacy System Upgrades & Maintenance: Its native support for robust serial communication protocols (RS-422/485) makes it a perfect drop-in replacement or upgrade for older manufacturing lines, minimizing software redevelopment and validation costs.

- Dedicated Machine Control: For standalone machinery like CNC mills, packaging equipment, or injection molding machines, the GP2500-SC41-24V provides a stable, no-frills control interface that is immune to the complexities and potential failure points of networked, software-heavy systems.

- Harsh Environment Operations: Built to industrial-grade specifications, this HMI is engineered to withstand the temperature fluctuations, vibration, and electrical noise common on the factory floor, ensuring consistent performance where consumer-grade tablets would fail.

A Technical Deep Dive into Enduring Performance

The longevity of the Pro-face GP2500-SC41-24V isn't accidental; it's the result of deliberate engineering choices prioritizing durability. Two core aspects stand out:

1. Industrial-Grade TFT Display & Backlight: The unit features a 10.4-inch TFT-LCD with a 640x480 VGA resolution. While modern resolutions are higher, this choice was optimized for industrial clarity and power efficiency. The display provides excellent readability for schematics, process values, and alarms. Critically, its backlight system is engineered for a high Mean Time Between Failures (MTBF), ensuring thousands of hours of continuous operation—a key consideration explored in the energy efficiency of HMI backlights.

2. Robust Communication Architecture: The inclusion of an RS-422/485 serial port is a testament to its industrial focus. Unlike Ethernet, this differential signaling interface offers superior noise immunity, which is essential for maintaining data integrity between the HMI and PLCs in electrically noisy environments. This robust physical layer prevents data corruption that could lead to costly production errors or machine downtime.

Key Technical Parameters at a Glance

For engineers and technicians, having the right data is crucial for integration and troubleshooting. Here are the core specifications for the GP2500-SC41-24V.

| Parameter | Specification |

|---|---|

| Display Type | TFT Color LCD |

| Screen Size | 10.4 inches |

| Resolution | 640 x 480 pixels (VGA) |

| Display Colors | 256 Colors (No Blink) / 64 Colors (Blink) |

| Backlight | CCFL (Cold Cathode Fluorescent Lamp) |

| Input Voltage | 24V DC |

| Communication Port | RS-422 / RS-485 |

| Touch Panel Type | Resistive Film (Analog) |

For a comprehensive breakdown of all specifications, you can Download the GP2500-SC41-24V Datasheet.

Strategic Advantage: The Power of Proven Technology

In an industry chasing the latest trends, there is a distinct strategic advantage in deploying technology that is thoroughly vetted and understood. The GP2500-SC41-24V represents this philosophy. Its software ecosystem is mature, its failure modes are well-documented, and replacement parts are readily available. For regulated industries or high-uptime manufacturing, this predictability is far more valuable than the marginal benefits of a newer, unproven interface. It removes variables from the operational equation, ensuring that the human-machine interface is a source of stability, not a point of failure.

Frequently Asked Questions (FAQ)

1. Is the resistive touchscreen suitable for modern industrial use?

Absolutely. While modern HMIs often use projected capacitive (PCAP) touch, the resistive screen on the GP2500-SC41-24V is a deliberate choice for industrial settings. It can be operated with gloved hands, styluses, or any object, offering versatility in environments where operators cannot use bare fingers. This is a key differentiator discussed in our guide to resistive vs. capacitive touchscreens.

2. What are the key considerations when replacing an older GP model with the GP2500-SC41-24V?

The primary considerations are physical fit (panel cutout dimensions) and software compatibility. The GP2500 series maintains a high degree of backward compatibility, often allowing for project files from older units to be easily migrated. Always verify the communication driver used in your existing project to ensure it's supported.

For further questions on integrating the GP2500-SC41-24V into your system or to explore our wider range of industrial LCD displays, we encourage you to contact our technical team for expert consultation.