Content last revised on December 8, 2025

The LM64C219: Engineering Clarity for Legacy Industrial Systems

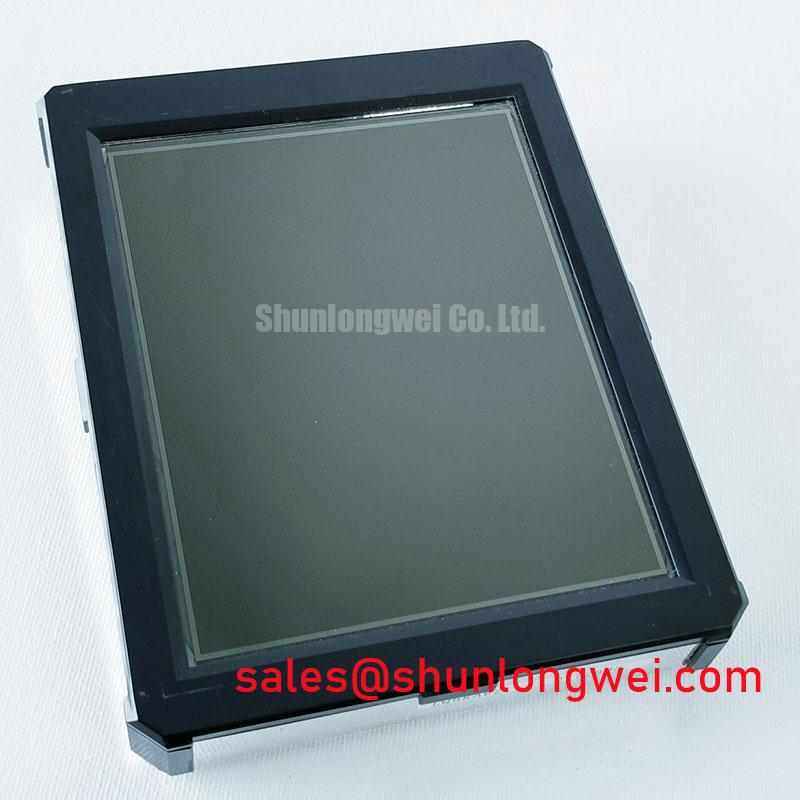

The Sharp LM64C219 is a monochrome LCD module engineered for long-term performance in environments that demand straightforward, reliable visual output. Delivering a crisp 640x480 VGA resolution on a 8.0-inch diagonal screen, this display utilizes Color Super-Twist Nematic (CSTN) technology to provide a clear, high-contrast viewing experience essential for industrial control panels and legacy equipment. Its key benefits include exceptional readability for critical data and simplified system integration. This module is purpose-built for applications where maintaining existing system architecture is paramount. For industrial control systems requiring drop-in replacements, this 8.0-inch VGA display is an optimal choice to ensure operational continuity without extensive redesign.

Application Scenarios & Value

Ensuring Operational Continuity in Legacy HMI and Control Systems

The LM64C219 is engineered as a direct-fit solution for maintaining and extending the life of critical industrial and medical equipment. Best fit for maintaining critical legacy industrial controllers, this 8.0-inch VGA display ensures operational continuity without costly system redesign. Consider an aging CNC machine or a factory process controller where the original display has failed. A full system upgrade would be prohibitively expensive and time-consuming, requiring hardware retrofitting and software redevelopment. The LM64C219, with its standard 640x480 VGA resolution and parallel data interface, serves as a form-fit-function replacement. Its CSTN-LCD technology provides the high-contrast, unambiguous monochrome readability that these focused applications were originally designed for, displaying essential parameters, alerts, and user prompts with clarity. By integrating this module, engineers can restore functionality with minimal downtime, preserving the validated performance of the original system. While the LM64C219 is ideal for this purpose, for systems requiring different form factors, the LM64183PR offers an alternative size and resolution for similar legacy applications.

Key Parameter Overview

Decoding Specifications for Seamless Legacy Integration

The technical specifications of the LM64C219 are tailored for straightforward integration into existing industrial frameworks. The panel’s architecture prioritizes reliability and compatibility over complex features, making it a robust choice for replacement and repair cycles. For a comprehensive review of all operational parameters and timing diagrams, please refer to the official documentation.

| Display Characteristics | Value |

| Manufacturer | Sharp |

| Display Technology | CSTN-LCD, STN, Normally Black, Transmissive |

| Diagonal Size | 8.0 inches |

| Resolution | 640x480 (VGA) |

| Active Area | 163.175 × 122.375 mm |

| Pixel Pitch | 0.255 x 0.255 mm |

| Integration & Electrical | Value |

| Signal Interface | Parallel Data (1-ch, 8-bit) |

| Backlight System | 1 pcs CCFL (Cold Cathode Fluorescent Lamp) |

| Mechanical & Environmental | Value |

| Application | Industrial, Medical Equipment |

Frequently Asked Questions (FAQ)

Technical Inquiries for the LM64C219 Module

What is the primary benefit of the CSTN (Color Super-Twist Nematic) display technology in this module?

The key benefit of its CSTN technology is providing high-contrast and clear readability, which is critical for displaying text-based data and simple graphics in industrial control environments. This ensures that operators can quickly and accurately read system statuses and alerts.

Does the LM64C219 require a separate backlight inverter?

Yes, the module includes a Cold Cathode Fluorescent Lamp (CCFL) as its backlight source but does not have an integrated driver. System designers must provision a compatible CCFL inverter to power the backlight. This modular approach was common in legacy designs and allows for flexibility in component selection.

Is the LM64C219 suitable for new product designs or primarily for replacement purposes?

With its parallel data interface and CCFL backlight, the LM64C219 is primarily intended for service, repair, and replacement in existing systems that were designed around these now-legacy technologies. This makes it an invaluable component for extending the operational life of machinery where redesign is not feasible. For more modern designs, engineers typically turn to TFT-LCD panels with LED backlights and LVDS or MIPI interfaces.

Application Vignette

A Closer Look: Restoring a Mission-Critical Process Controller

An automotive parts manufacturer relies on a two-decade-old automated welding controller that has proven exceptionally reliable. Recently, its monochrome screen became unreadable, halting a critical production sub-assembly line. The challenge was clear: restore the HMI without undertaking a months-long, high-cost project to replace and re-validate the entire control system. The on-site engineering team identified the failed part as a Sharp display, and the LM64C219 presented itself as the ideal solution.

Its 8.0-inch size and mounting points were a direct match for the existing enclosure, while the parallel data interface connected seamlessly to the controller's host board. Within hours, the new display was installed. The machine powered up, and the familiar, sharp black-and-white user interface was restored. The system’s value was not in cutting-edge features but in its ability to be a "plug-and-play" fix. This eliminated the need for software changes, interface adapters, or mechanical modifications, underscoring the strategic value of sourcing components engineered for legacy compatibility. To explore the broader considerations when choosing industrial displays, read our guide on industrial vs. consumer displays.

For expert assistance in sourcing legacy components or identifying compatible display solutions for your specific application, contact our technical sales team for a consultation.