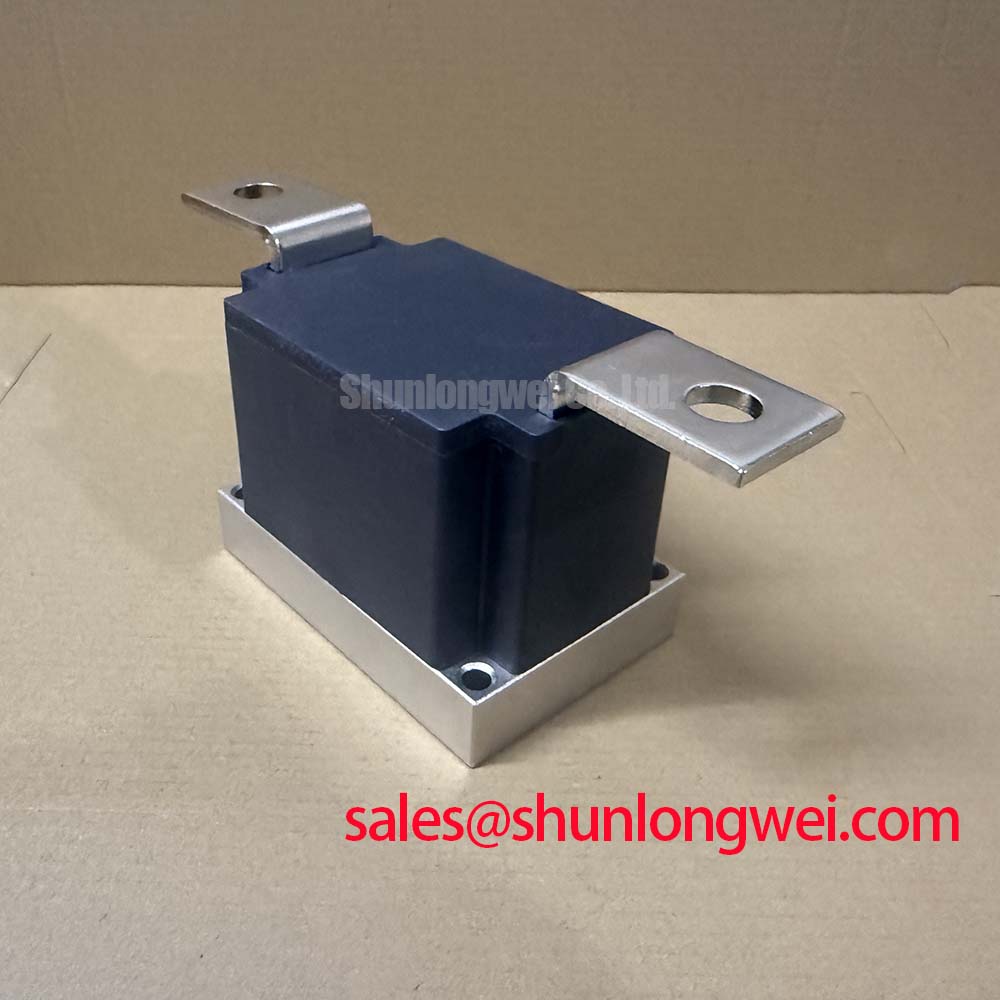

Proton-Electrotex MT/D3-740-24-D-N | 2400V Thyristor Module

Engineered to Outlast: Solder-Free Reliability in High-Power Systems

For engineers designing high-power systems, solder joint fatigue is a persistent threat to long-term reliability. The Proton-Electrotex MT/D3-740-24-D-N confronts this challenge directly, delivering unparalleled mechanical robustness with its solder-free pressure-contact design. This three-phase thyristor/diode module offers core specifications of 2400V | 740A | 18000A I_TSM, providing a foundation for exceptionally durable power conversion. Its primary benefits are the elimination of solder fatigue failures and a significantly enhanced power cycling lifespan. This construction provides superior longevity in thermally cyclic environments compared to conventional soldered modules, which are susceptible to joint degradation and premature failure.

Technical Questions on the MT/D3-740-24-D-N

- What is the primary advantage of the MT/D3-740-24-D-N's pressure-contact technology? Its main advantage is enhanced long-term reliability. By eliminating solder joints, the design mitigates a primary failure mode—thermal and mechanical fatigue—which is critical in applications with frequent temperature fluctuations, leading to extended operational life and reduced maintenance costs.

- How does a 2400V repetitive peak off-state voltage (V_DRM) benefit system design? A 2400V rating provides a crucial safety margin, especially for equipment operating on 690V AC industrial power grids. This high breakdown voltage ensures the device can withstand significant voltage transients and line disturbances without damage, a key factor for building robust systems for Variable Frequency Drives (VFDs) and rectifiers in harsh electrical environments.

- What does the "D" housing designation signify for installation and thermal management? The "D" type housing specifies the module's physical dimensions and mounting footprint, which are standardized for industrial applications. This ensures mechanical compatibility with existing heatsink designs and busbar layouts, simplifying both new system integration and potential field replacements. For a deeper understanding of thermal performance, consulting resources on thermal resistance (Rth) is beneficial.

Strategic Value of Mechanical Endurance in Modern Power Conversion

In industries such as renewable energy, traction, and heavy manufacturing, the total cost of ownership (TCO) is increasingly prioritized over initial component cost. Unscheduled downtime in these sectors can result in financial losses that far exceed the price of any single component. The core design pillar of the Proton-Electrotex MT/D3-740-24-D-N is its intrinsic mechanical endurance. The pressure-contact system isn't just a feature; it's a strategic choice that aligns with the industry's shift towards 'design for reliability'. This approach ensures that power electronics can sustain operational integrity over years of service, even when subjected to the relentless mechanical vibrations and thermal stresses found in mining excavators, wind turbine converters, or railway propulsion systems.

Deployments Demanding Unyielding Mechanical and Electrical Integrity

The MT/D3-740-24-D-N is specified for power conversion stages where reliability is paramount and environmental conditions are demanding. Its architecture makes it a prime candidate for:

- High-Power Industrial Rectifiers: Used as the main input bridge for large-scale DC power supplies, electro-chemical processing, and welding applications where its high surge current tolerance (18000A) is critical for surviving line faults.

- Motor Soft Starters: Provides controlled starting for large AC induction motors in pumps, fans, and compressors, where the pressure-contact design withstands the repeated thermal stresses of start-stop cycles.

- Grid-Tied Converters: In battery storage and renewable energy systems, its robust construction ensures a reliable connection point between the power source and the utility grid.

For high-power rectifiers where operational lifespan under severe thermal cycling is paramount, the MT/D3-740-24-D-N's pressure-contact design makes it a superior foundation over traditional soldered modules.

Field-Proven Reliability: Pressure-Contact in Action

Consider a large-scale mining operation where a multi-megawatt conveyor belt is driven by a high-voltage AC motor. The drive's input rectifier is subjected to constant vibration from the machinery and wide ambient temperature swings. In this scenario, a conventional soldered module faces a high risk of solder joint cracking over time, leading to catastrophic failure and costly production halts. The deployment of the MT/D3-740-24-D-N in this rectifier stage fundamentally changes the reliability equation. Its pressure-contact interfaces are immune to the solder fatigue that plagues other modules, ensuring a consistent, low-resistance connection and contributing to the uninterrupted operation of the entire conveyor system. This shift from a potential point of failure to a pillar of strength exemplifies the module's value proposition.

A Data-Centric Look at Pressure-Contact vs. Soldered Designs

When evaluating power modules, engineers must consider factors beyond baseline electrical ratings. The construction method is a critical determinant of long-term performance. The table below offers a factual comparison to aid in the decision-making process, contrasting the pressure-contact technology of the Proton-Electrotex MT/D3-740-24-D-N with conventional soldered modules. For systems operating on lower voltage grids, a device such as the SKKT570/16E may present a different set of design trade-offs.

| Attribute | Pressure-Contact Technology (MT/D3-740-24-D-N) | Conventional Soldered Modules |

|---|---|---|

| Primary Failure Mode | Resistant to fatigue-related failures. | Susceptible to solder joint cracking from thermal/power cycling. |

| Power Cycling Capability | Significantly higher due to absence of materials with mismatched thermal expansion coefficients. | Limited by the fatigue life of the solder layers. |

| Serviceability | Allows for easier replacement of semiconductor elements in the field. | Failure typically requires replacement of the entire module. |

| Vibration Resistance | Inherently robust due to high-pressure mechanical connections. | Performance can degrade if vibrations lead to solder joint stress. |

Inside the MT/D3-740-24-D-N: The Engineering of Pressure-Contact

What is the main advantage of the MT/D3-740-24-D-N's construction? Its pressure-contact design provides superior mechanical and thermal cycling reliability. The core of this module's exceptional durability lies in its solder-free architecture. Instead of relying on solder, which can degrade and crack over time, the internal semiconductor elements are pressed together under immense force. This method can be compared to the precision assembly of a high-end mechanical watch, where components are interlocked with physical integrity, versus being simply glued. This physical connection ensures a stable, low-resistance path for both current and heat, remaining unaffected by the repeated expansion and contraction that causes fatigue in soldered designs. This engineering choice is central to preventing common field failures, a topic further explored in our guide to IGBT failure analysis.

Core Specifications for System Design

The following parameters are essential for integrating the MT/D3-740-24-D-N into your power system design. For a complete list of specifications, please download the official datasheet.

| Parameter | Value |

|---|---|

| Repetitive Peak Off-State and Reverse Voltage (V_DRM, V_RRM) | 2400 V |

| Average On-State Current (I_T(AV)) @ T_c=100°C | 740 A |

| Surge On-State Current (I_TSM) for 10 ms | 18000 A |

| I²t for Fusing for 10 ms | 1.62 MA²s |

| Thermal Resistance, Junction to Case (R_th(j-c)) | 0.038 °C/W |

| Isolation Voltage (V_ISOL) @ 50 Hz | 4000 V (RMS) |

Download the Datasheet for MT/D3-740-24-D Series

Designing for a Future of Uninterrupted Power

As industrial automation and grid-level power systems become increasingly complex and critical, the focus of component selection is shifting from simple metrics to lifetime operational integrity. Adopting devices like the Proton-Electrotex MT/D3-740-24-D-N is more than a component upgrade; it represents a strategic investment in system longevity. By engineering out known failure mechanisms like solder fatigue, this thyristor module enables the development of power converters and rectifiers that are not only powerful but are built to endure, paving the way for a future where high-power electronics deliver on their promise of sustained, uninterrupted performance.