Content last revised on October 22, 2025.

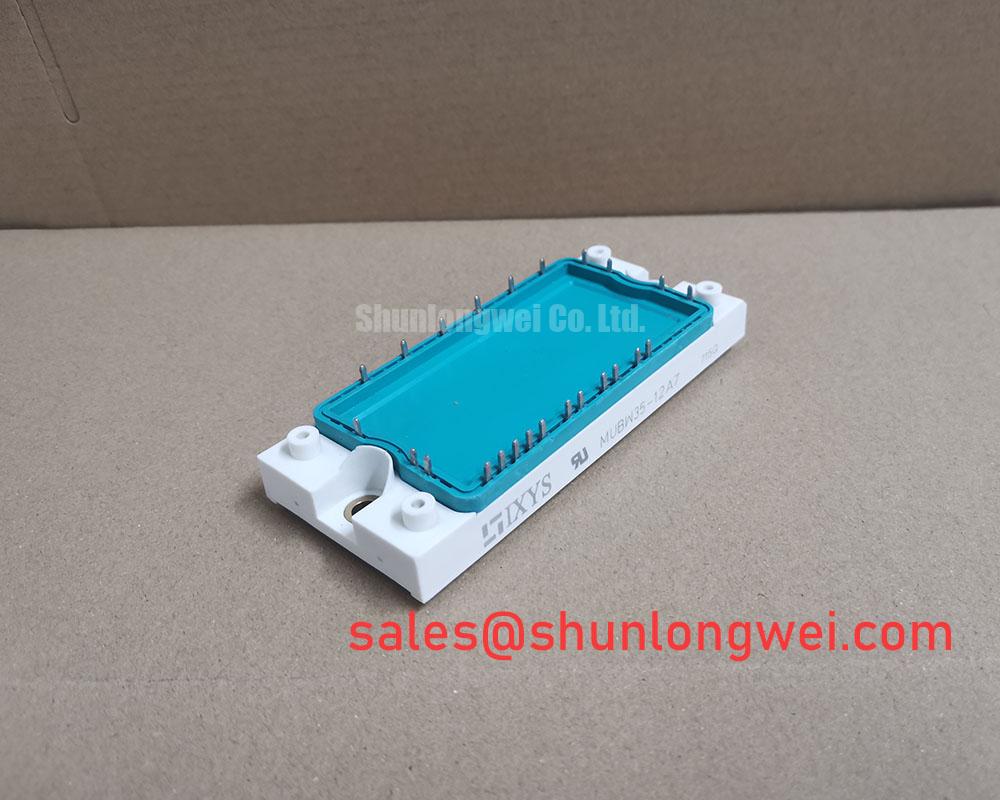

MUBW35-12A7: Technical Data & Application Guide for 1200V Converter Brake Unit

Engineering a Thermally Robust Front-End for AC Motor Drives

The MUBW35-12A7 is a 1200V converter brake unit engineered to deliver exceptional thermal reliability and power density for compact motor drives. It integrates a three-phase input rectifier and an efficient brake chopper into a single, isolated module. With key specifications of 1200V | 35A (Rectifier) | 35A (IGBT) | V_ISO = 3600V~, this device offers two primary engineering benefits: enhanced thermal cycling capability and significantly simplified system assembly. It provides a definitive answer to the challenge of implementing a compact, thermally efficient front-end and dynamic braking solution in modern AC motor drive systems. For space-constrained motor drives requiring robust thermal management and integrated braking, the MUBW35-12A7 provides an optimized single-module solution.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the MUBW35-12A7 are tailored for high-reliability applications where both performance and operational lifespan are critical. The parameters below highlight the module's robust design, directly impacting everything from heatsink selection to overall system efficiency.

| Parameter | Symbol | Value | Engineering Significance |

|---|---|---|---|

| Max. DC Forward Current (Rectifier Diode, TC=80°C) | IdAVM | 35 A | Defines the continuous current handling capability of the input rectifier, crucial for sizing the module for a specific motor power rating. |

| Collector-Emitter Voltage (IGBT) | VCES | 1200 V | Ensures sufficient voltage margin for operation on 400V/480V AC lines, providing reliability against DC bus voltage spikes. |

| Collector Current (IGBT, TC=80°C) | IC80 | 35 A | Specifies the brake chopper's current capacity, determining its ability to manage regenerative energy from the motor. |

| Collector-Emitter Saturation Voltage (Tvj=125°C, IC=35A) | VCE(sat) | Typ. 2.1 V | A lower VCE(sat) indicates lower conduction losses in the brake IGBT, resulting in less heat generation and higher overall system efficiency. |

| Thermal Resistance, Junction-to-Case (per IGBT) | RthJC | 1.0 K/W | This critical value quantifies the efficiency of heat transfer from the semiconductor chip to the module case. A low RthJC is the foundation of superior thermal management. |

| Isolation Test Voltage | VISOL | 3600 V~ | Guarantees high electrical isolation between the power circuit and the baseplate, ensuring safety and simplifying system grounding strategies. |

Download the MUBW35-12A7 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Compact Industrial Automation

The MUBW35-12A7 is engineered for designers of modern AC Motor Drive systems, particularly where space is at a premium and reliability cannot be compromised. Its primary value lies in simplifying the power stage design by combining two essential functions into one thermally efficient package.

A high-fidelity engineering scenario is the design of a compact Variable Frequency Drive (VFD) for a packaging conveyor system that undergoes frequent start-stop cycles. During deceleration, the motor acts as a generator, creating regenerative energy that increases the DC Bus Voltage. The MUBW35-12A7's integrated brake chopper manages this by shunting the excess energy to a dynamic braking resistor, preventing overvoltage faults. The critical challenge in such a compact VFD is heat dissipation. The module's Direct Copper Bonded (DCB) substrate provides a low thermal resistance path, efficiently drawing heat away from both the rectifier diodes and the brake chopper IGBT. This prevents thermal throttling and significantly enhances the drive's long-term reliability under demanding, repetitive-load conditions. While the MUBW35-12A7 is ideal for this power class, systems requiring higher input current might evaluate rectifier modules like the VUB72-16NO1, which offers a 72A rating in a similar topology.

- Small to Medium Power AC Motor Drives

- Servo Drives and Robotics

- Pump and Fan Controls

- Power Supplies with Active Front Ends

Frequently Asked Questions (FAQ)

How does the Direct Copper Bonded (DCB) substrate in the MUBW35-12A7 improve system reliability?

The DCB substrate provides superior thermal performance and high voltage isolation. By creating a very efficient path for heat to move from the semiconductor to the heatsink (low RthJC), it keeps the chip operating at a lower temperature. This reduction in thermal stress directly translates to a longer operational lifetime and higher reliability, especially in applications with frequent power cycling.

What is the primary advantage of integrating a brake chopper into the same module as the three-phase rectifier?

Integration reduces overall system size, simplifies the bill of materials (BOM), and streamlines the manufacturing process. It eliminates the need for a separate braking module, reducing wiring complexity, potential points of failure, and simplifying thermal design to a single heatsink interface. This leads to a more compact, cost-effective, and reliable drive design.

The datasheet specifies a 7th Generation XPT™ IGBT for the brake chopper. What does this mean for dynamic braking applications?

The use of 7th Gen Trench Gate Field Stop IGBT Technology (XPT™) means the brake chopper operates with lower conduction and switching losses. This efficiency is crucial because it minimizes the amount of waste heat generated during braking events. The result is improved overall system efficiency, reduced stress on the braking resistor, and better thermal stability for the entire module.

Technical Deep Dive

The Reliability Synergy of DCB Substrates and XPT™ Technology

The robust performance of the MUBW35-12A7 stems from the intelligent combination of its mechanical construction and advanced semiconductor technology. The foundation of its thermal excellence is the Direct Copper Bonded (DCB) substrate. This structure acts like a multi-lane superhighway for heat, allowing thermal energy to escape the semiconductor junctions far more effectively than older, less direct bonding methods. This low thermal impedance is critical for reliability, as it directly minimizes the temperature swings at the chip level during load cycles, which is a primary factor in preventing material fatigue and extending module life.

This superior thermal foundation is paired with a 7th generation XPT™ IGBT in the brake chopper circuit. The efficiency of this IGBT can be understood through an analogy: its switching behavior is like a door that opens and closes almost instantaneously. Older IGBTs are like heavy, slow doors; there is a longer period where they are partially open, wasting significant energy as heat during the transition. The XPT™ IGBT minimizes this "in-between" time, drastically cutting down switching losses. This synergy—efficient heat generation from the IGBT and efficient heat removal by the DCB substrate—is what enables the MUBW35-12A7 to deliver reliable power management in a compact form factor.

Industry Insights & Strategic Advantage

Meeting the Demands for Power Density and Lower TCO

The design philosophy of the MUBW35-12A7 directly addresses two key trends in industrial power conversion: the push for greater power density and the focus on reducing the total cost of ownership (TCO). As factory automation and robotics advance, engineers are tasked with fitting more powerful Servo Drive and VFD systems into smaller physical footprints. An integrated module like this is a key enabler, replacing multiple discrete components with a single, highly optimized unit. This not only saves valuable PCB and enclosure space but also aligns with design principles for systems compliant with standards like IEC 61800.

Furthermore, the strategic advantage extends beyond initial design. While sourcing individual components might appear to offer a lower upfront cost, the MUBW35-12A7 reduces TCO through multiple vectors. It simplifies inventory management, slashes assembly time and cost, and, most importantly, enhances field reliability. The robust thermal design minimizes downtime and maintenance calls, a critical financial consideration over the lifecycle of industrial equipment. This makes the module a strategic choice for OEMs aiming to build competitive, reliable, and space-efficient power control systems.

Strategic Integration for Future-Ready Drive Designs

Selecting the MUBW35-12A7 is a strategic decision that favors design simplicity, thermal robustness, and long-term reliability. By integrating the essential front-end and braking functions into a single module built on a proven, thermally efficient platform, it provides engineers with a foundational block to accelerate development cycles and deliver more compact and dependable AC motor control solutions. This approach moves beyond simple component selection, offering a system-level solution that addresses the core engineering challenges of modern industrial automation.