Content last revised on January 22, 2026

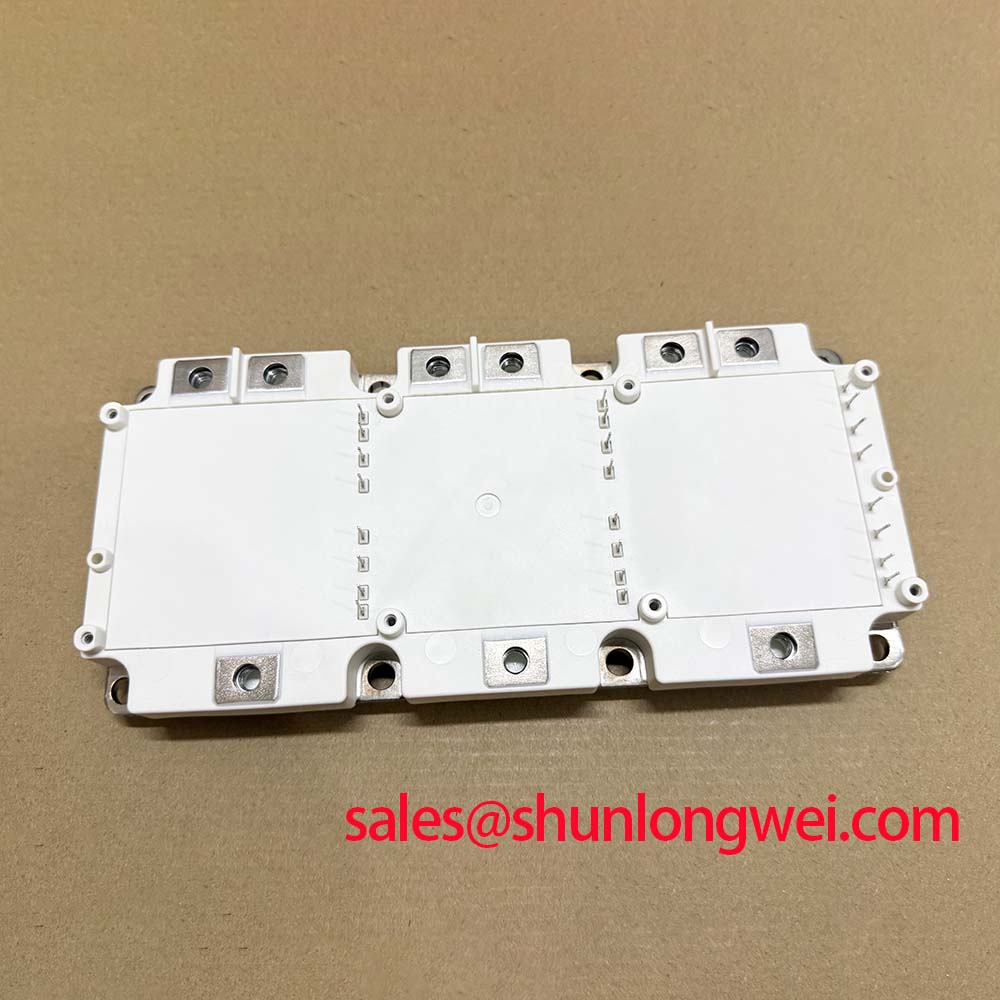

IFS150B12N3T4_B31: 1200V HybridPACK™ IGBT for EV Inverters

The Infineon IFS150B12N3T4_B31 is a 1200V automotive-grade IGBT module architected for superior thermal management and long-term reliability in electric vehicle traction inverters. It features key specifications of 1200V | 150A | Rth(j-c) 0.17 K/W, delivering exceptional thermal headroom and robust operational stability. For engineers questioning how to achieve dependable performance under the demanding thermal cycles of EV applications, this module's low thermal resistance and integrated temperature sensing provide a direct and effective solution for managing heat dissipation and ensuring drivetrain longevity.

Technical Deep Dive

A Closer Look at Thermal Pathway Engineering

The operational resilience of the IFS150B12N3T4_B31 is fundamentally rooted in its sophisticated thermal design. The module exhibits a very low thermal resistance from junction to case (Rth(j-c)) of 0.17 K/W per IGBT. This parameter acts much like the diameter of a pipe, where a larger opening allows for greater flow; here, a lower thermal resistance value signifies a more efficient pathway for waste heat to escape from the semiconductor chip to the heatsink. This efficiency is critical in preventing the junction temperature from exceeding its maximum operating limit of 175°C, even under high-current conditions typical of vehicle acceleration. Furthermore, the integration of an NTC temperature sensor provides a direct, real-time feedback mechanism for the vehicle's control unit, enabling precise thermal monitoring and proactive power modulation to safeguard the inverter system.

Industry Insights & Strategic Advantage

Meeting Automotive Demands for Drivetrain Longevity

The automotive industry's push towards electrification places immense pressure on the reliability of power electronics. Components like the IFS150B12N3T4_B31 are at the forefront of this challenge, directly impacting the long-term viability and safety of electric vehicles. Its design, qualified according to automotive standards, addresses the core failure mechanisms in power modules, such as bond wire lift-off and solder fatigue, which are often exacerbated by the intense thermal cycling in EV drive cycles. By ensuring a robust thermal pathway and stable mechanical construction within the HybridPACK™ package, this module helps engineering teams meet stringent lifetime and reliability targets, contributing to a lower total cost of ownership and enhanced brand reputation for vehicle manufacturers.

Success Stories / Deployment Snippets

Enabling Robust Performance in EV Traction Inverters

While specific customer deployments are confidential, modules with the architecture of the IFS150B12N3T4_B31 are benchmarked for main inverter applications in both hybrid and full battery electric vehicles. In these systems, the module's ability to efficiently manage heat is a key enabler for achieving high power density. What is the key benefit of the integrated NTC sensor? It provides direct, real-time thermal feedback for precise system protection. This allows for more compact inverter designs without compromising on performance or operational safety margins. The module serves as a foundational component in powertrains designed for sustained high-torque output and fast-charging capabilities, where thermal stability is directly linked to vehicle performance and user experience.

Application Scenarios & Value

Core Applications: Where Thermal Resilience Creates Value

The IFS150B12N3T4_B31 is purpose-built for high-stress automotive environments where efficient power conversion and unwavering reliability are critical. Its primary application is in the main traction inverters of electric and hybrid vehicles, which are responsible for converting DC battery power into the AC power needed to drive the electric motor. The module's robust thermal characteristics also make it a suitable candidate for other high-power automotive applications.

- EV and HEV Main Traction Inverters: Manages the primary power flow from the battery to the motor, enabling vehicle propulsion with high efficiency and durability.

- Commercial Electric Vehicle Drives: Provides the necessary power handling and reliability for light commercial vehicles, electric buses, and transport trucks.

- High-Performance Electric Powertrains: Supports the demanding requirements of performance and luxury EVs where thermal headroom is essential for delivering maximum torque.

With its low Rth(j-c) of 0.17 K/W, this module is the definitive choice for compact, high-power density EV inverters requiring robust thermal headroom. For a deeper understanding of how IGBTs form the core of modern power systems, explore our guide on the backbone of high-efficiency power systems.

Intra-Series Comparison & Positioning

Positioning within the HybridPACK™ Family

The Infineon HybridPACK™ family encompasses a range of modules tailored for different power levels and application requirements within the automotive sector. The IFS150B12N3T4_B31, with its 150A nominal current rating, is positioned as a robust solution for mainstream passenger EV applications. Compared to lower current-rated modules in the series, it offers increased power output capability. When evaluated against modules with higher current ratings, it provides a cost-effective solution for systems where 150A is sufficient, optimizing the balance between performance and system cost. The key differentiator often lies in the balance of conduction and switching losses, and this module is optimized to provide excellent all-around performance for typical EV drive cycles. For systems requiring different current levels, the related FS100R12KT4G offers a 100A alternative for lower-power applications.

Key Parameter Overview

Critical Parameters for Thermal System Design

Engineers evaluating the IFS150B12N3T4_B31 for their designs should focus on the following performance indicators which are central to its function in thermally demanding applications. A thorough review of these specifications is a critical step in system-level thermal simulation and design validation. Further details can be found in the official product datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Nominal Collector Current (Ic nom) | 150 A |

| Collector-Emitter Saturation Voltage (Vce sat, typ. at Ic nom) | 1.85 V |

| Thermal Resistance, Junction-to-Case per IGBT (Rth(j-c)) | 0.17 K/W |

| Max. Operating Junction Temperature (Tj op) | 175 °C |

| Short Circuit Withstand Time (tsc) | 8 µs |

As the electric vehicle market continues to evolve, the demand for power modules that offer higher power density, improved thermal efficiency, and uncompromising reliability will only intensify. The IFS150B12N3T4_B31 represents a key building block for current and next-generation EV platforms, providing designers with a component that is not only powerful but also engineered for the long-term durability expected in the automotive world. Understanding the nuances of its thermal performance is crucial for unlocking its full potential, a topic further explored in our article on unlocking IGBT thermal performance.