Content last revised on January 20, 2026

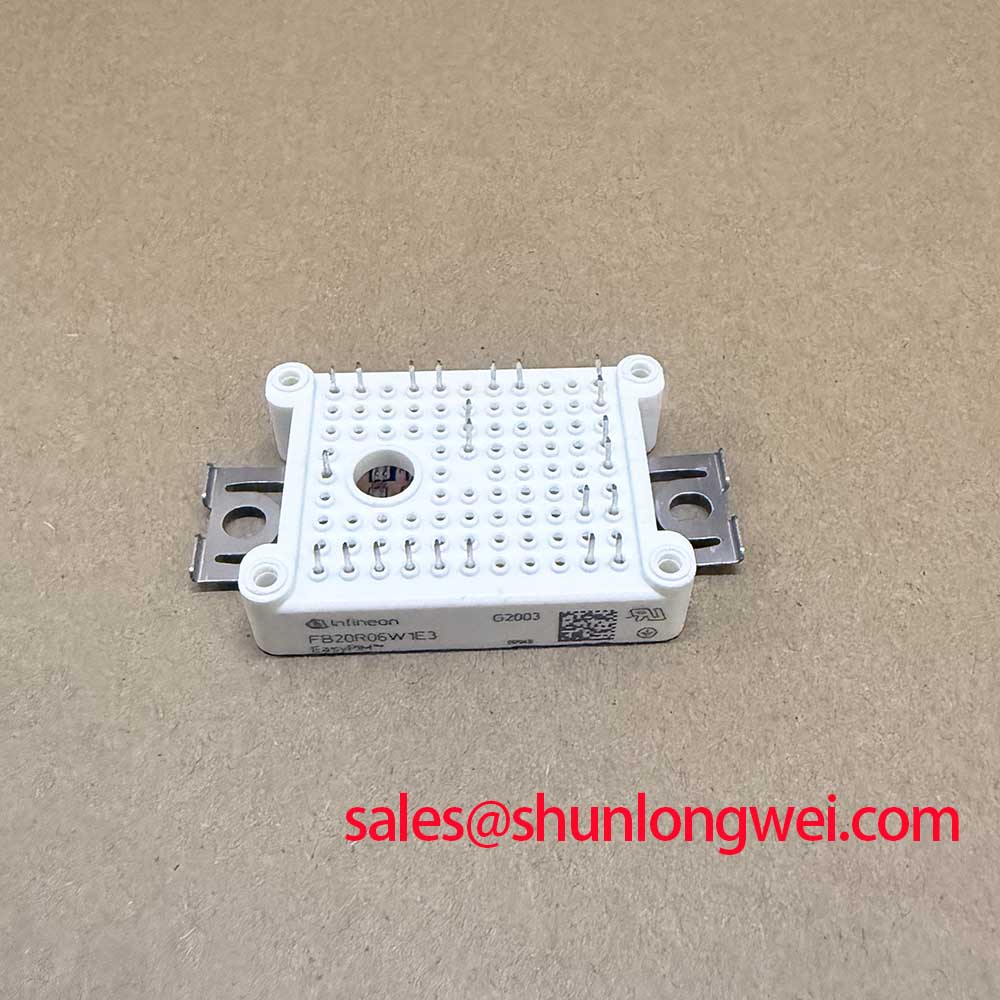

FB20R06W1E3: Technical Data for 600V PIM IGBT Module

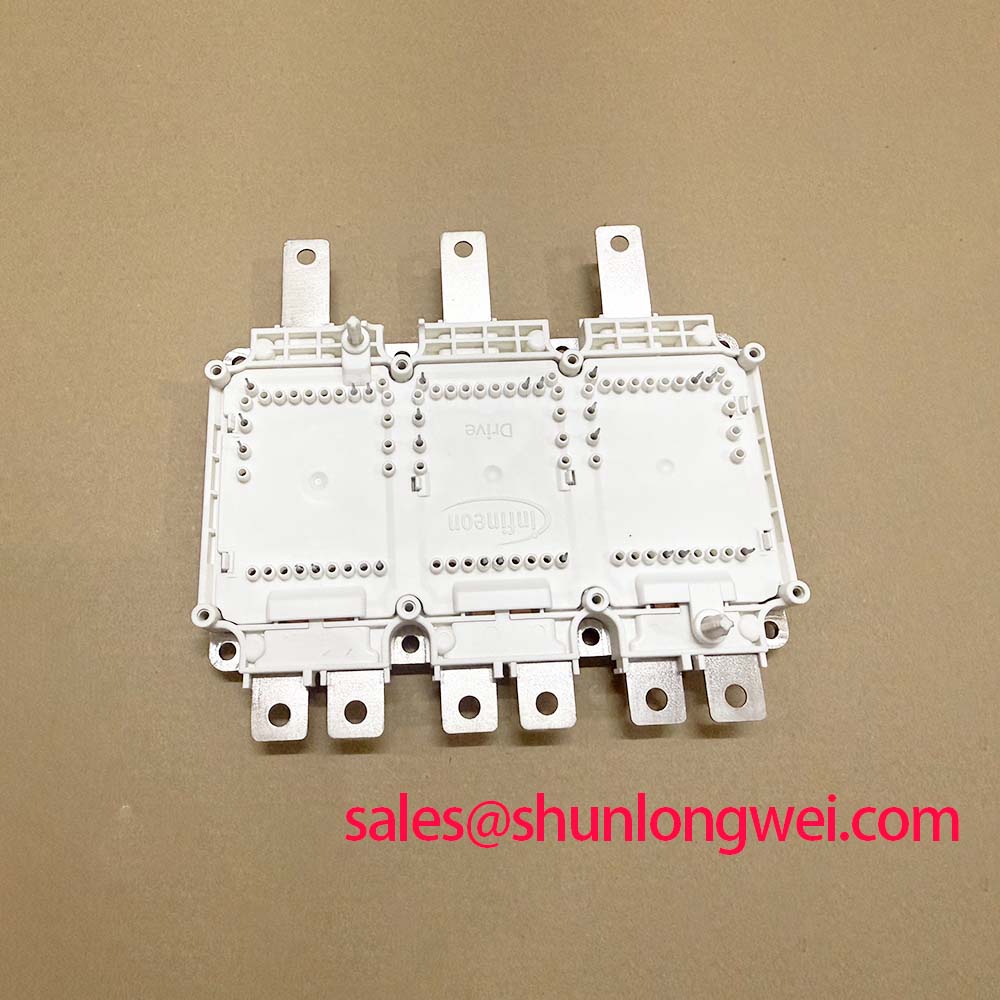

Engineered for robust thermal performance and system reliability, the Infineon FB20R06W1E3 is a 600V, 20A PIM IGBT module integrating Trench/Fieldstop IGBT3 technology. Key Specifications: 600V VCES | 20A IC nom | Tvj max 175°C. Benefits include optimized switching losses and enhanced thermal stability. This module directly addresses the engineering need for compact, thermally efficient power stages by integrating a three-phase bridge, brake chopper, and NTC into a single EasyPIM™ housing, thereby simplifying thermal management through a unified heat sink interface.

Strategic Power Conversion in a Consolidating Market

The drive towards higher power density and simplified assembly in industrial automation places significant demands on power semiconductor modules. As system designers face pressures to reduce equipment footprints and bills of materials (BOM), integrated modules like the PIM (Power Integrated Module) architecture become critical. The Infineon FB20R06W1E3 exemplifies this trend by co-packaging a three-phase inverter, brake chopper, and rectifier stage. This high level of integration not only streamlines the manufacturing process but also enhances system reliability by minimizing interconnects and optimizing the thermal path from the silicon to the heat sink. Such consolidation is pivotal for creating cost-effective and dependable motor drives and auxiliary power units that meet modern industrial standards.

A Comparative Framework for Module Evaluation

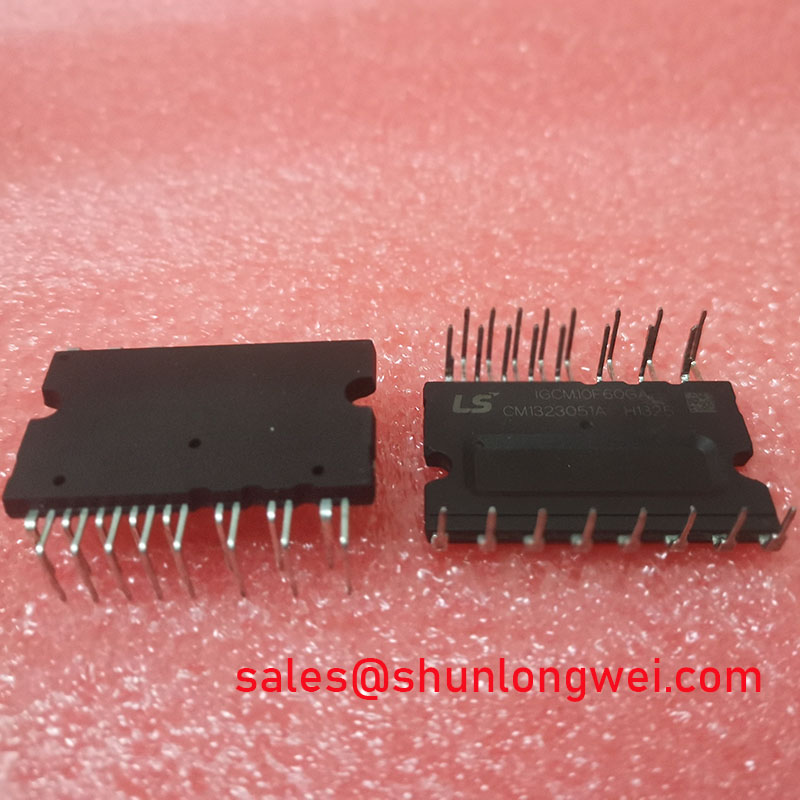

When evaluating integrated power modules for motor drive applications, engineers must weigh several competing factors. The FB20R06W1E3 sets a specific benchmark with its combination of 600V Trench/Fieldstop IGBT3 technology and a comprehensive PIM configuration. For systems requiring a different voltage class or current handling, a component like the FS50R06W1E3 provides a similar integrated approach but with different power ratings. The selection process involves a detailed analysis of datasheet parameters to align the module's capabilities with the application's specific load profile and thermal budget. This data-driven approach ensures that the chosen module provides the necessary performance margin without over-engineering the solution.

This comparison is for informational purposes only, based on publicly available datasheets. It does not constitute a recommendation or endorsement. Engineers must conduct their own validation to determine the suitability of any component for their specific application.

Application Arenas Demanding Integrated Reliability

The integrated nature of the FB20R06W1E3 makes it a strong candidate for power conversion systems where space, assembly cost, and thermal management are primary design drivers. Its architecture is particularly well-suited for:

- Auxiliary Inverters: Providing reliable power for ancillary systems in larger industrial equipment, transportation, and commercial vehicles. The compact EasyPIM™ package simplifies integration into space-constrained enclosures.

- Motor Drives: Ideal for low-to-medium power variable frequency drives (VFDs), servo drives, and general-purpose motor controls. The integrated brake chopper is essential for managing regenerative energy in dynamic load applications. What is the benefit of its integrated NTC thermistor? It allows for direct monitoring of module temperature, a critical input for thermal protection algorithms.

- Air Conditioning Systems: The module's efficiency and compact design are valuable in commercial and residential HVAC compressor and fan controls, contributing to overall system energy savings.

For motor drives where thermal budget is a primary constraint, the FB20R06W1E3's Al2O3 substrate with low thermal resistance offers a distinct advantage over modules with less efficient thermal interfaces.

A Technical Dissection of the FB20R06W1E3

At its core, the FB20R06W1E3 leverages Infineon's Trench/Fieldstop IGBT3 technology, a mature platform known for its balance between conduction and switching losses. The module's design incorporates an Aluminum Oxide (Al2O3) substrate, which serves as an electrical insulator while providing a competent thermal pathway to the heatsink. This material choice is a key factor in the module's overall thermal resistance. The thermal resistance, Rth(j-c), can be compared to the width of a pipeline; a lower value signifies a wider pipe, allowing heat (the fluid) to be evacuated more effectively from the IGBT junction to the case, thus enabling higher operational reliability and longevity. The internal layout includes six IGBTs in a three-phase bridge configuration, a seventh IGBT for the brake chopper, and a full diode bridge rectifier, all within the EasyPIM™ housing. An integrated NTC thermistor provides a direct means for temperature sensing, facilitating crucial over-temperature protection mechanisms in the drive's control logic.

Key Technical Specifications Overview

The following parameters are critical for evaluating the FB20R06W1E3 in a power system design. For a comprehensive list of specifications, please download the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 600 V |

| Nominal Collector Current (IC nom) | 20 A |

| Max. Junction Temperature (Tvj max) | 175 °C |

| Inverter IGBT VCE(sat) (Typical at Tvj=25°C) | 1.50 V |

| Total Power Dissipation (Ptot) | 94.0 W |

Frequently Asked Questions (FAQ)

What is the primary benefit of the Trench/Fieldstop IGBT3 technology used in the FB20R06W1E3?

Trench/Fieldstop IGBT3 technology provides a well-balanced performance, offering low saturation voltage (VCE(sat)) to minimize conduction losses and optimized switching characteristics to reduce energy loss during on/off transitions. This balance is crucial for achieving high efficiency in motor drive applications.

How does the integrated NTC thermistor improve system design?

The integrated NTC thermistor simplifies the design of the system's thermal protection circuit. It provides a direct and accurate measurement of the module's substrate temperature, allowing the control system to implement precise over-temperature warnings or shutdowns, thereby protecting the IGBTs from thermal runaway and enhancing overall system longevity.

Is the FB20R06W1E3 suitable for paralleling to achieve higher current output?

The datasheet for the FB20R06W1E3 specifies a positive temperature coefficient for its VCE(sat). This characteristic is favorable for paralleling IGBTs, as it helps to ensure thermal stability and balanced current sharing between parallel-connected modules. However, engineers must still implement careful gate drive design and symmetrical layout practices as outlined in resources like practical guides to robust gate drive design.

Strategic Outlook for System Integration

The Infineon FB20R06W1E3 represents a strategic component choice for designers aiming to optimize the total cost of ownership in low-power motor drives and auxiliary inverters. Its PIM architecture moves beyond simple component specifications, offering a solution that addresses manufacturing efficiency, thermal engineering, and long-term reliability in a single, compact package. As industrial systems continue to demand smaller, more efficient, and more reliable power electronics, the value proposition of such highly integrated modules will only increase, making them a cornerstone of next-generation power conversion design.