Content last revised on January 14, 2026

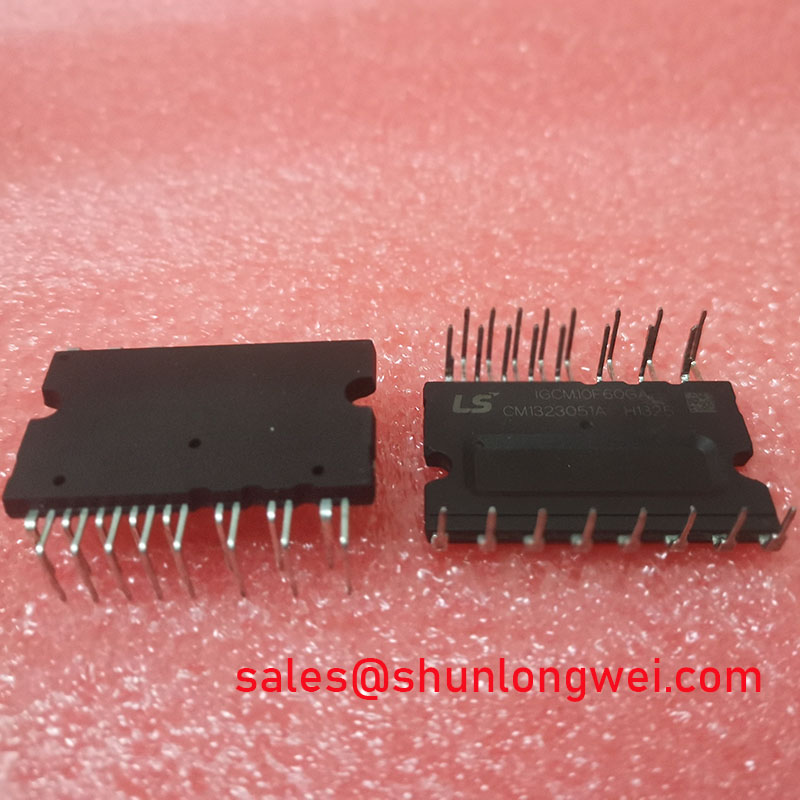

Infineon IGCM10F60GA | Compact IPM for High-Efficiency Motor Control

Product Highlights: Streamlining Low-Power Drive Design

The Infineon IGCM10F60GA is a member of the highly regarded CIPOS™ Mini family, engineered to accelerate the development and enhance the reliability of low-power motor drives. This is not just an IGBT; it's a fully integrated three-phase inverter solution in a compact DIP package. It combines robust TRENCHSTOP™ IGBT3 technology with an optimized SOI gate driver, delivering a turnkey solution for applications where space, bill-of-materials (BOM) cost, and time-to-market are critical design constraints.

- High-Level Integration: Includes six 600V TRENCHSTOP™ IGBTs, a full gate driver suite, bootstrap diodes, and comprehensive protection features, significantly reducing external component count.

- Optimized for Motor Drives: Specifically designed for variable frequency drives in home appliances and light industrial equipment up to ~800W.

- Robust Protection: Features Under-Voltage Lockout (UVLO), Over-Current protection (OC), and an integrated NTC thermistor for real-time temperature monitoring, preventing common causes of IGBT failure.

- Simplified Assembly: The single, compact DIP package streamlines PCB layout and manufacturing processes.

A Deeper Look at the Core Technology

The performance of the IGCM10F60GA stems from the synergistic combination of its silicon and control logic. Two elements are particularly crucial for design engineers.

First, the use of Infineon TRENCHSTOP™ IGBT3 technology provides an excellent balance between low conduction losses (VCE(sat)) and moderate switching losses. For the typical switching frequencies found in motor control (4-16 kHz), this technology hits a sweet spot. It minimizes static power dissipation during on-state operation without incurring the excessive switching losses that can plague faster IGBTs in this frequency range. This translates directly to higher inverter efficiency and reduced heatsink requirements.

Second, the integrated SOI (Silicon-on-Insulator) gate driver is a key enabler of the module's reliability and ease of use. It provides excellent noise immunity and latch-up protection, critical in electrically noisy appliance environments. The driver's built-in cross-conduction prevention logic and shoot-through protection eliminate the need for complex external dead-time management, simplifying the control interface and protecting the IGBTs from catastrophic failure.

Application Scenarios & Engineering Value

The IGCM10F60GA excels in applications where efficiency, reliability, and compact design are paramount. Its integrated nature provides tangible value in several key areas:

- Residential Air Conditioner Fans & Compressors: The module's high level of integration simplifies the inverter design, allowing it to fit within constrained spaces. The onboard NTC thermistor provides essential feedback for thermal management, ensuring long-term reliability in demanding, high-duty-cycle operation.

- Washing Machine & Dishwasher Motor Drives: In these cost-sensitive applications, the IGCM10F60GA dramatically reduces the BOM by eliminating the need for separate gate drivers, bootstrap components, and current-sensing circuitry. This leads to a more compact, cost-effective, and reliable control board.

- Low-Power Industrial Automation: For general-purpose servo and Variable Frequency Drive (VFD) applications, this module offers a significant advantage in design cycle time. Engineers can focus on control algorithms rather than spending time on the intricacies of gate drive and protection circuit design.

Key Technical Specifications

The following table provides a quick reference for the essential parameters of the IGCM10F60GA. For a comprehensive overview, please Download the Datasheet.

| Parameter | Value |

|---|---|

| Inverter Part Number | IGCM10F60GA |

| Max. DC Collector Current (IC) @ TC=25°C | 10 A |

| Collector-Emitter Voltage (VCES) | 600 V |

| Collector-Emitter Saturation Voltage (VCE(sat)) @ IC=5A | 1.65 V (Typ.) |

| Isolation Voltage (VISO) | 2000 VRMS (1 min) |

| Package Type | DIP 36x21 |

| Integrated Features | Gate Driver, Bootstrap Diodes, NTC, OC Protection, UVLO |

Frequently Asked Questions (FAQ)

What is the primary benefit of using this IPM (Intelligent Power Module) over discrete IGBTs and a separate driver IC?The primary benefit is system-level optimization and reliability. The IGCM10F60GA's driver is perfectly matched to the characteristics of the internal IGBTs. This eliminates guesswork in gate drive design, reduces parasitic inductance between the driver and IGBTs, and ensures protection features like over-current shutdown are triggered at precisely the right thresholds. This results in a smaller, more reliable, and faster-to-develop solution.

How should the integrated NTC thermistor be used in a design?The NTC provides a direct, real-time measurement of the module's substrate temperature. This data should be fed back to the main system microcontroller. The controller can then implement a thermal foldback strategy (reducing motor current as temperature rises) or trigger a complete shutdown if a critical temperature limit is exceeded. This is a far more accurate and responsive method of thermal management than relying on an external heatsink sensor.

For detailed application notes or to discuss how the IGCM10F60GA can fit into your next project, please contact our technical team.