Content last revised on November 14, 2025

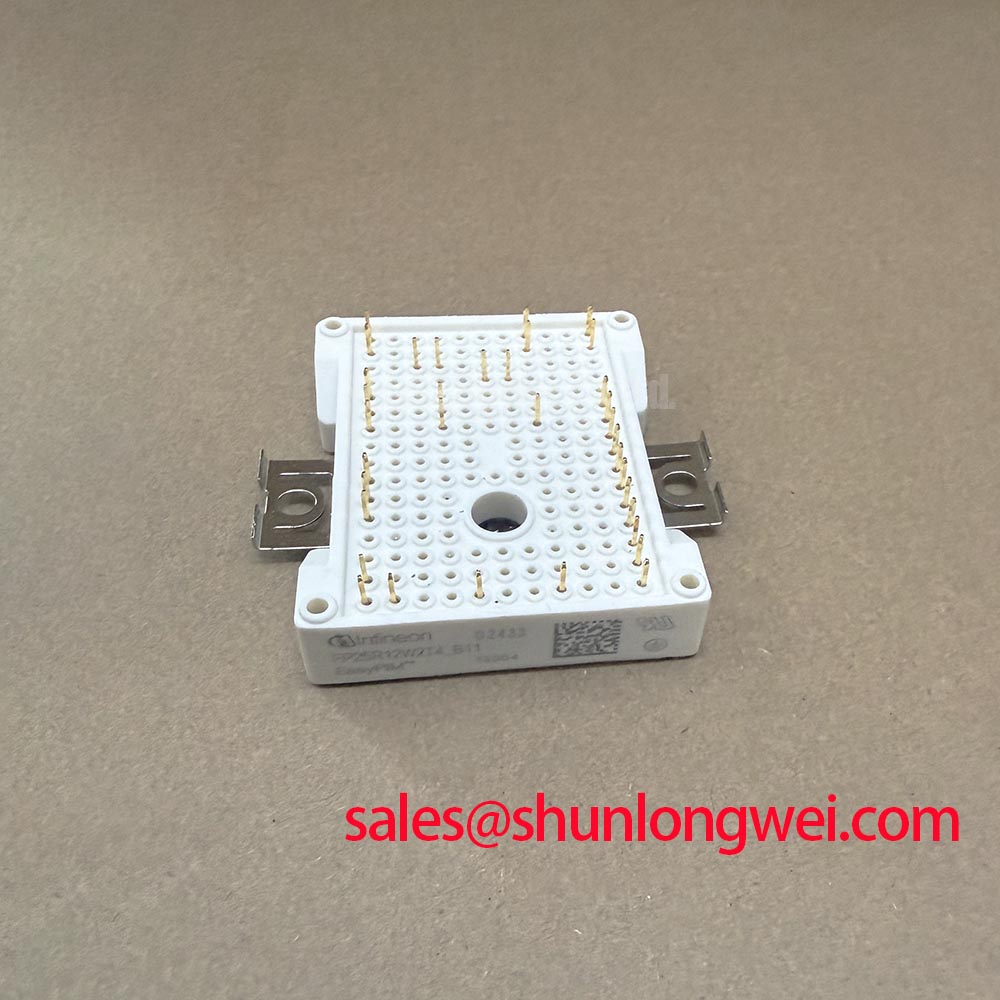

FP25R12W2T4_B11: 1200V 25A PIM IGBT Module Analysis

Optimized for Thermal Stability in Compact Power Systems

The Infineon FP25R12W2T4_B11 is an integrated power module delivering robust thermal performance for variable-speed drives. Featuring a 1200V collector-emitter voltage and a 25A nominal current, this module integrates a three-phase rectifier, brake chopper, and inverter stage. Its key benefits include enhanced thermal management and simplified system design. For engineers evaluating thermal performance, the integrated NTC thermistor provides precise temperature feedback, directly addressing the challenge of preventing overheating in densely packed applications.

Meeting Industrial Demands for Higher Power Density

The relentless push towards smaller, more powerful industrial systems places immense strain on thermal management. As footprints for servo drives and automation components shrink, dissipating heat effectively becomes a primary design obstacle. Power modules are at the heart of this challenge. The FP25R12W2T4_B11 directly addresses this trend by leveraging Infineon's TRENCHSTOP™ IGBT4 technology. This technology is engineered not just for electrical efficiency but also for superior thermal conductivity, enabling designers to build more compact and reliable systems without compromising on power output or operational lifespan. This focus on thermal performance is a key enabler for next-generation, high-density industrial equipment.

Engineered for Thermally Demanding Applications

The specific electrical and thermal characteristics of the FP25R12W2T4_B11 make it a strong candidate for a range of power conversion applications where space is limited and thermal reliability is critical. Its integrated nature simplifies the design and assembly of multi-stage power systems.

- Servo Drives: In precision robotics and CNC machinery, servo drives experience dynamic loads that generate significant thermal stress. The module's low VCE(sat) minimizes conduction losses, while the integrated NTC allows for real-time temperature monitoring to protect against overload conditions.

- Small Industrial Drives: For general-purpose motor control, such as conveyor belts and pumps, this module provides a complete power stage solution in a single compact package, reducing both PCB footprint and assembly complexity.

- UPS Systems: Uninterruptible Power Supplies require high efficiency and proven reliability. The robust diode and IGBT combination within this module ensures dependable performance during critical power backup operations.

For AC motor drives under 4 kW prioritizing long-term reliability in environments with elevated ambient temperatures, this module's low thermal resistance makes it a highly suitable design choice.

Core Specifications for Thermal Design

The following parameters are central to evaluating the FP25R12W2T4_B11 for your power system design. Full specifications are available in the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200 V |

| DC Collector Current (IC nom) | 25 A |

| Collector-Emitter Saturation Voltage (VCEsat) at IC=25A, Tvj=25°C | 1.85 V (Typ.) |

| Total Power Dissipation (Ptot) at TC=25°C | 195 W |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) per IGBT | 0.64 K/W |

| Maximum Junction Temperature (Tvj max) | 150 °C |

Download the complete FP25R12W2T4_B11 Datasheet

Inside the FP25R12W2T4_B11: A Focus on Thermal Engineering

A deeper look into the module's technology reveals how its thermal performance is achieved. The core of the inverter stage utilizes Infineon's TRENCHSTOP™ IGBT4 chips. This generation of IGBTs provides a favorable trade-off between switching losses (Eon, Eoff) and conduction losses, characterized by a low collector-emitter saturation voltage (VCE(sat)). Lower VCE(sat) directly translates to less power dissipated as heat during operation, easing the burden on the cooling system.

The Role of Thermal Resistance

A critical parameter for any power module is its thermal resistance, junction-to-case (Rth(j-c)). This value acts like the diameter of a pipe for heat flow; a lower Rth(j-c) signifies a wider pipe, allowing heat to escape more easily from the active semiconductor junction to the heatsink. The FP25R12W2T4_B11's specified thermal resistance of 0.64 K/W per inverter IGBT indicates an efficient pathway for heat extraction, a key factor in achieving long-term operational reliability. What is the primary benefit of its efficient thermal pathway? It allows for smaller heatsink designs or higher power output in thermally constrained systems. For engineers looking to expand their knowledge, a comprehensive in-depth analysis of IGBT modules can provide valuable context.

Real-World Thermal Resilience

Consider a compact variable frequency drive (VFD) integrated directly into a motor housing. In this scenario, airflow is restricted, and ambient temperatures can be high. The FP25R12W2T4_B11's integrated NTC thermistor becomes a vital safety feature. By providing a direct, real-time measurement of the module's substrate temperature, the VFD's control system can proactively scale back the output current or trigger a controlled shutdown if the temperature approaches its maximum limit (Tvj max), preventing catastrophic failure and enhancing the overall system's durability.

Data-Driven Evaluation for Your Application

When evaluating power modules, comparing key datasheet parameters provides objective data for your specific design constraints. The FP25R12W2T4_B11 is part of a broad family of power modules, and its selection should be based on a clear analysis of system requirements.

For instance, while a different module might offer slightly lower switching losses, it may come at the cost of a higher VCE(sat), making it less suitable for applications with lower switching frequencies where conduction losses dominate. The FP25R12W2T4_B11 presents a well-balanced profile for many industrial motor drive applications. For systems that may require a different power class, the FP35R12W2T4 offers similar features with a higher current rating of 35A. Understanding these trade-offs is fundamental to proper IGBT datasheet decoding.

Future-Proofing Designs with Integrated Thermal Management

As power electronics continue to evolve, the integration of sensing and protection features directly into power modules will become increasingly standard. The FP25R12W2T4_B11, with its integrated NTC thermistor, represents a key step in this direction. This approach not only simplifies the bill of materials and assembly but also creates a more robust and intelligent power system. Future designs will likely build upon this foundation, incorporating more sophisticated monitoring to enable predictive maintenance and further enhance the reliability and efficiency of industrial and power conversion systems.

Frequently Asked Questions (FAQ)

1. What is the primary benefit of the integrated NTC thermistor in the FP25R12W2T4_B11?The integrated NTC provides a direct and accurate measurement of the module's baseplate temperature. This allows the system's controller to implement precise over-temperature protection, preventing thermal runaway and significantly improving the long-term reliability of the power stage.

2. How does the TRENCHSTOP™ IGBT4 technology in this module impact my design?TRENCHSTOP™ IGBT4 technology offers a balanced performance between conduction losses (low VCE(sat)) and switching losses. This efficiency reduces the amount of waste heat generated, which can lead to smaller heatsink requirements, lower cooling costs, and a more compact overall system design.

3. Is this module suitable for applications with high switching frequencies?The FP25R12W2T4_B11 is optimized for the typical switching frequencies found in industrial motor drives, which generally range from a few kHz up to around 16 kHz. While it can operate at higher frequencies, designers must carefully analyze the trade-off, as increased switching losses will generate more heat, requiring more substantial thermal management.

4. What does the "PIM" designation in "PIM IGBT Module" signify?PIM stands for Power Integrated Module. It indicates that the device integrates multiple power electronic stages into a single package. In the case of the FP25R12W2T4_B11, this includes the input rectifier bridge, a brake chopper IGBT, and the three-phase output inverter, simplifying system construction.