Content last revised on January 16, 2026

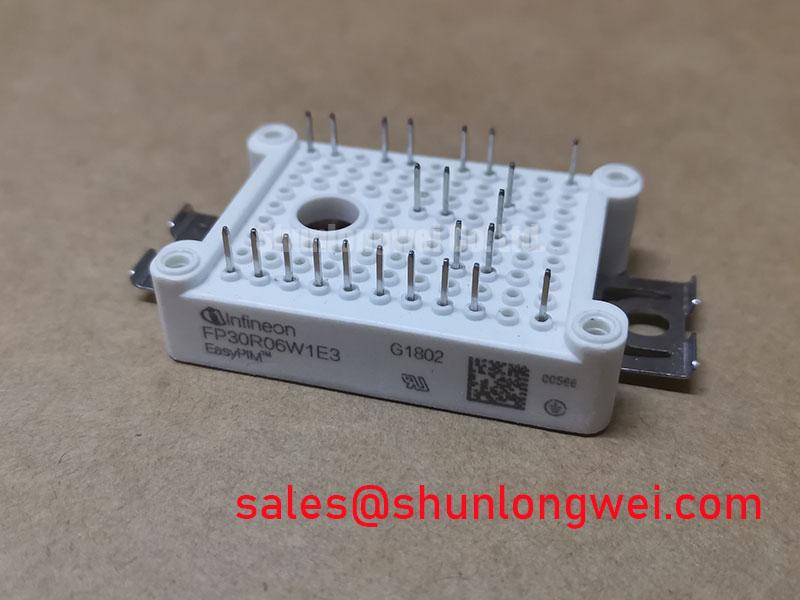

Infineon FP35R12W2T4 | Integrated PIM Module for Compact Motor Drives

Engineered for Efficiency and Integration

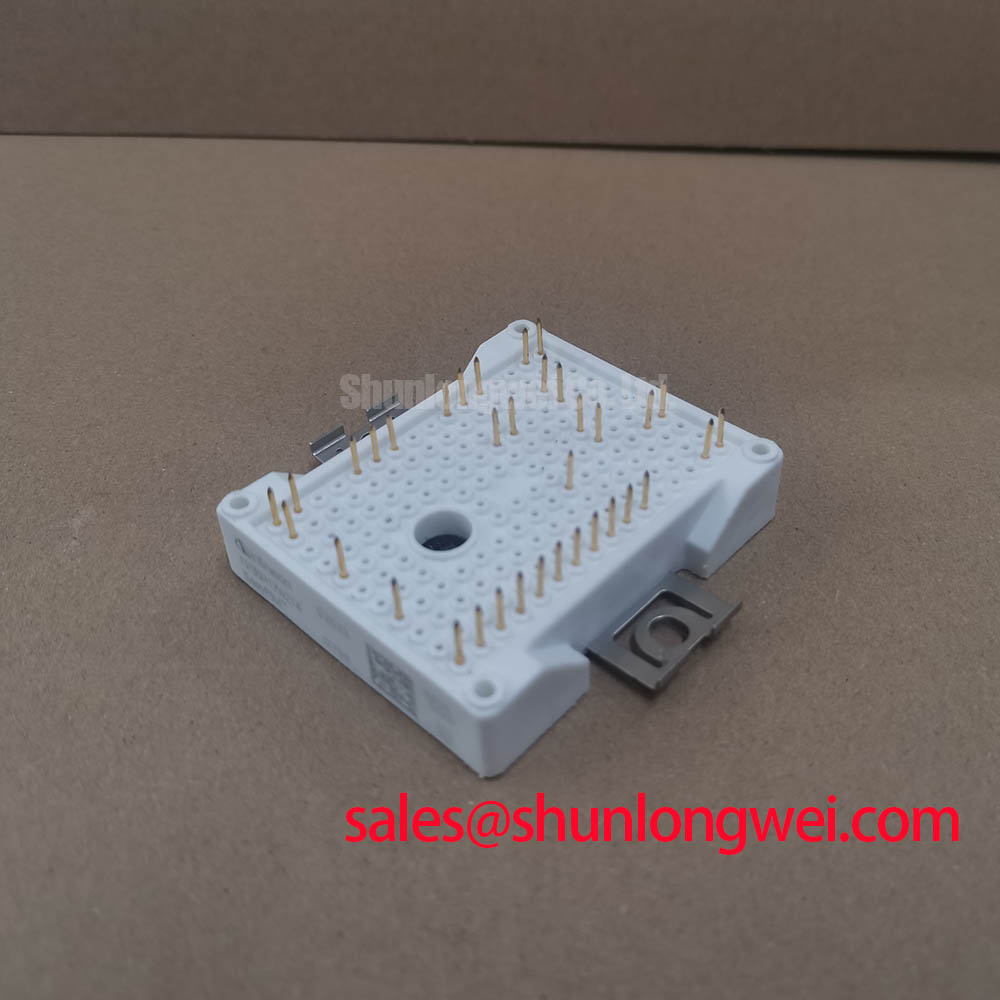

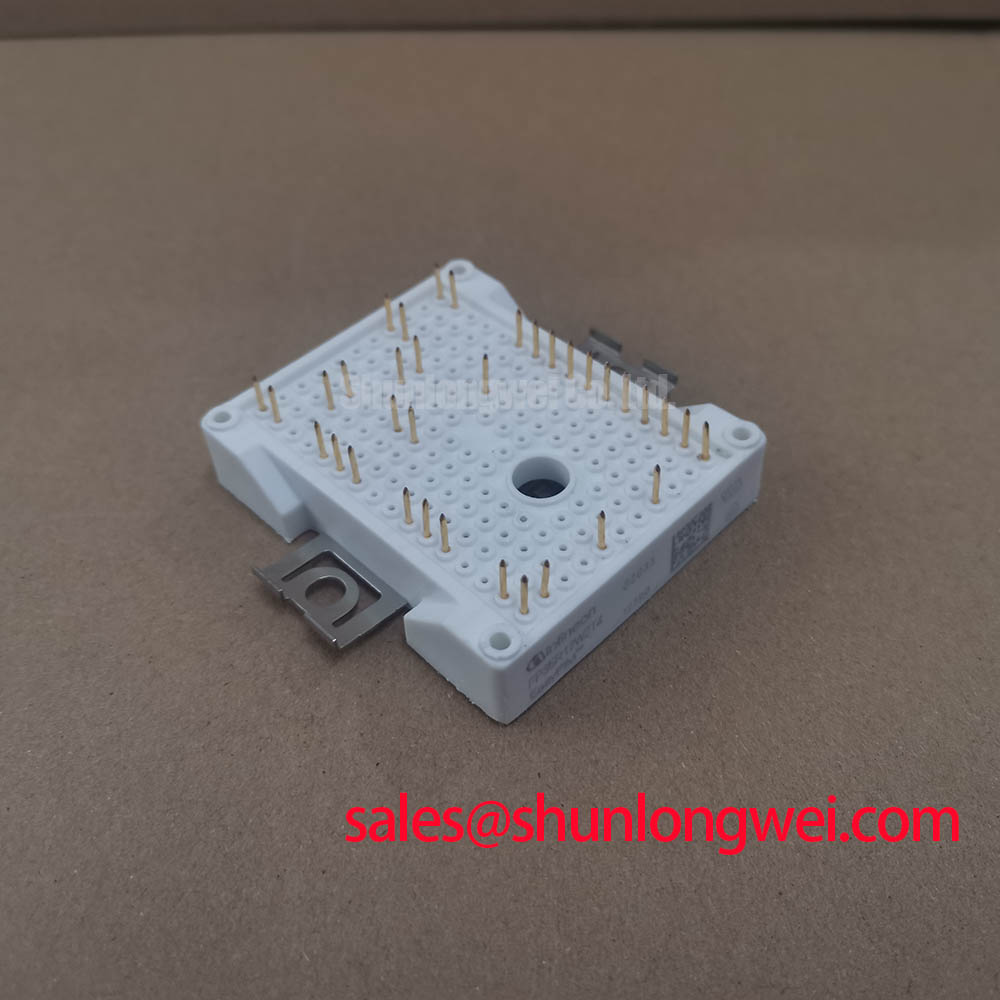

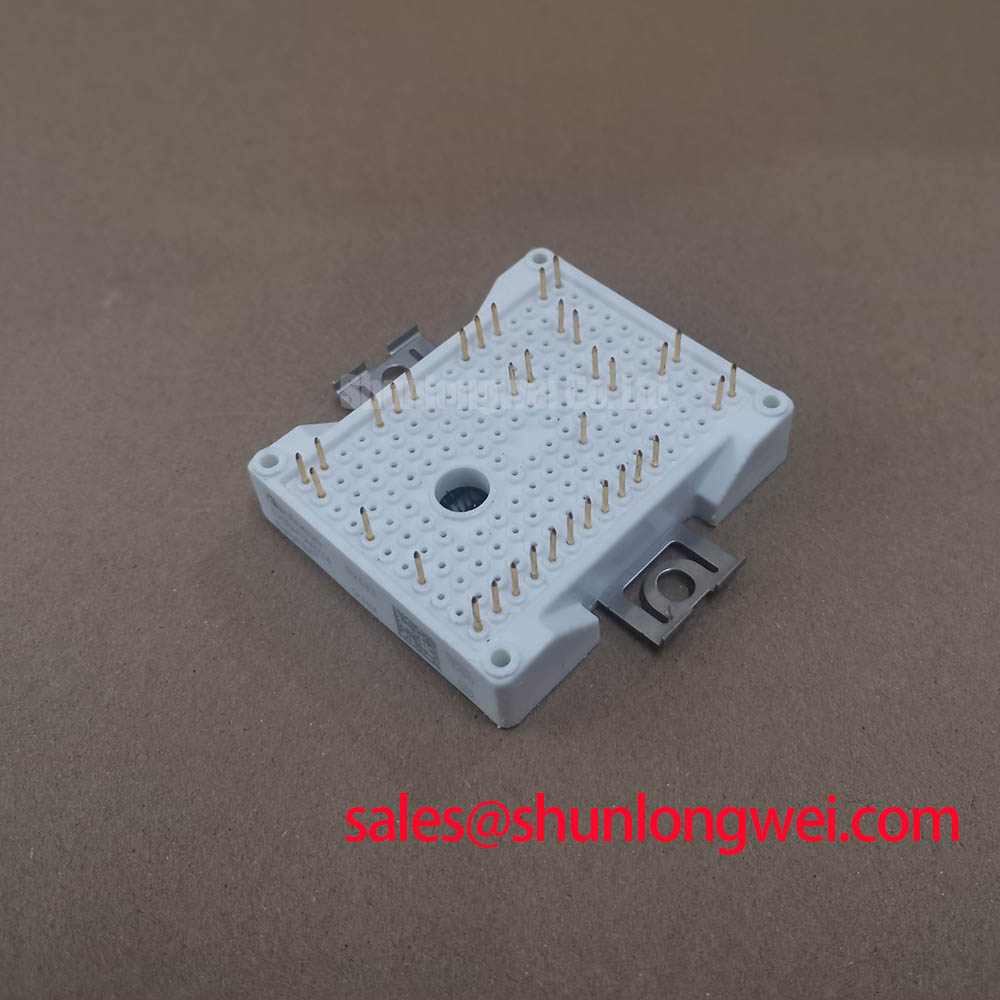

The Infineon FP35R12W2T4 is a highly integrated Power Integrated Module (PIM) designed for low-to-medium power motion control applications. Housed in the industry-proven EconoPIM™ 2 package, this module combines a three-phase input rectifier, a three-phase inverter, and a brake chopper into a single, compact component. It’s a workhorse solution for engineers seeking to reduce system size, simplify assembly, and accelerate time-to-market for their power conversion systems.

- Rating: 1200V / 35A

- Topology: PIM (Rectifier + Inverter + Brake Chopper)

- IGBT Technology: TRENCHSTOP™ IGBT4

- Core Applications: AC Motor Drives, Servo Drives, UPS, Low-Power Inverters

Technical Deep Dive: The Power of Integration and Balanced Performance

The core value of the FP35R12W2T4 lies in its intelligent combination of topology and silicon technology. By integrating three essential power stages, it fundamentally simplifies the design of a Variable Frequency Drive (VFD). This consolidation eliminates the need for multiple discrete components, reduces PCB real estate, and minimizes complex wiring and potential points of failure. For design teams, this translates directly into lower assembly costs and enhanced system reliability.

At its heart, the module employs Infineon's TRENCHSTOP™ IGBT4 chips. This technology represents a masterful engineering trade-off. It provides a significantly lower collector-emitter saturation voltage (VCE(sat)) compared to older non-punch-through (NPT) technologies, leading to lower conduction losses. While not designed for the ultra-high frequencies of the latest IGBTs, its switching characteristics are optimized for the typical 4-16 kHz range found in most industrial motor drives. This balance ensures high efficiency without introducing the gate drive complexity required by faster-switching devices.

Optimized Performance for Core Applications

The specific features of the Infineon FP35R12W2T4 deliver tangible benefits in demanding industrial environments:

- AC & Servo Drives: The integrated brake chopper is critical for managing regenerative energy during motor deceleration. This prevents DC bus overvoltage faults, enabling precise and rapid control cycles essential for applications like robotic servo drives and conveyor systems.

- Compact Automation Systems: For decentralized drives or cabinet-mounted inverters where space is at a premium, the PIM topology is a game-changer. The single-module approach allows for a much smaller overall system footprint.

- Uninterruptible Power Supplies (UPS): The inherent reliability of the EconoPIM™ package, combined with the integrated NTC thermistor for real-time temperature monitoring, provides the robustness required for critical power backup systems.

Key Electrical Characteristics at a Glance

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200 V |

| Continuous Collector Current (IC nom) | 35 A |

| Collector-Emitter Saturation Voltage (VCEsat, typ) @ IC=35A | 1.85 V |

| Gate-Emitter Threshold Voltage (VGE(th)) | 5.8 V |

| Package | EconoPIM™ 2 |

Strategic Value in Modern Automation

While newer IGBT generations offer lower losses, the FP35R12W2T4 holds a unique strategic position. It represents a mature, cost-effective, and highly reliable platform. For projects where time-to-market, system simplicity, and proven field performance are paramount, this IGBT module is often a superior choice. Its all-in-one nature de-risks the design process, making it an ideal building block for a wide range of standard industrial drives up to approximately 15 kW. It embodies the engineering principle of using the right tool for the job, providing a robust solution without the unnecessary cost or complexity of higher-performance-tier components.

Engineer's FAQ

Q: What are the key considerations for the gate drive circuit for the FP35R12W2T4?

A: The TRENCHSTOP™ IGBT4 requires a standard gate drive voltage, typically +15V for turn-on and -8V to -15V for secure turn-off, especially to prevent parasitic turn-on. A dedicated gate driver IC with a Miller clamp function is recommended to ensure robust performance under high dV/dt conditions.

Q: How does the integrated NTC thermistor improve system design?

A: The built-in NTC provides a direct, real-time measurement of the module's baseplate temperature. This allows the system controller to implement precise thermal protection, derating, or shutdown protocols, preventing catastrophic IGBT failures due to overheating and maximizing the module's operational lifespan.

For detailed application support or to discuss your specific design requirements for the FP35R12W2T4, please contact our technical team.