Content last revised on November 15, 2025

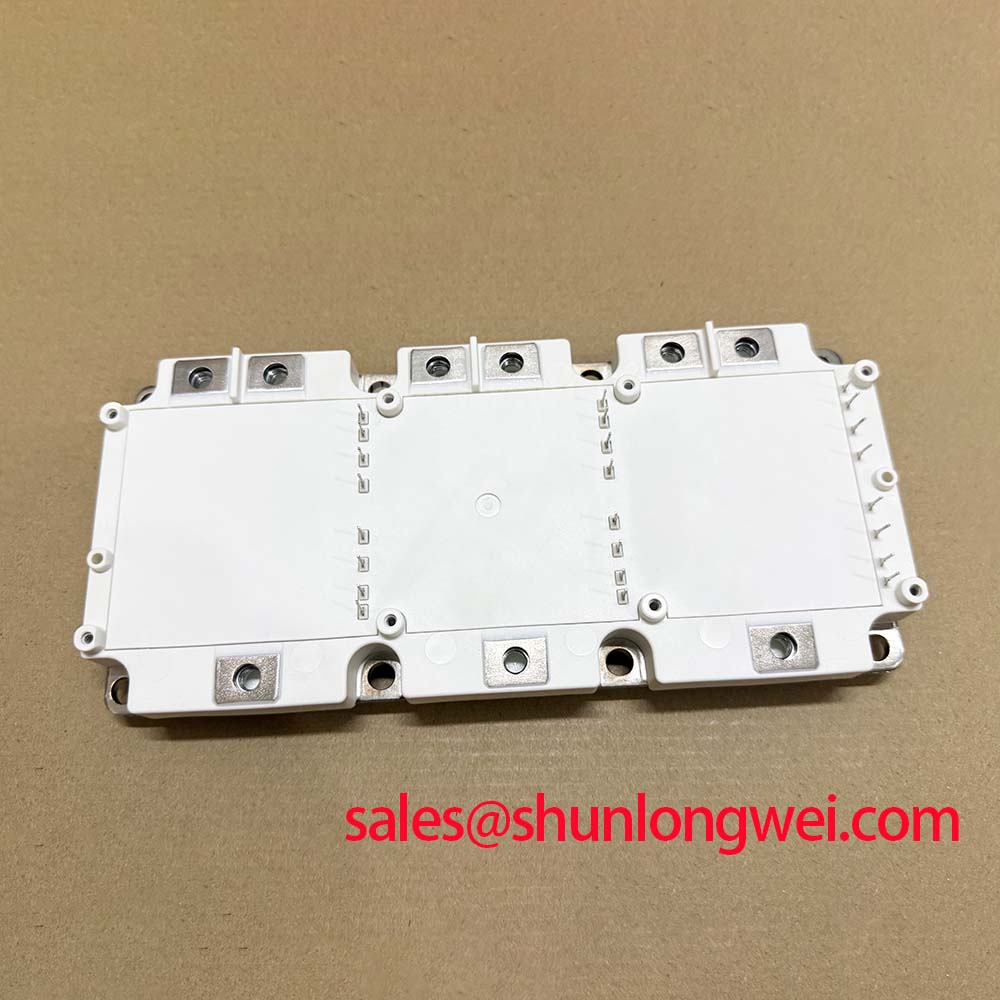

BSM50GD120DN2 IGBT: 1200V/50A Module for Efficient Power Design

The BSM50GD120DN2 is a high-efficiency IGBT module designed to minimize thermal load through superior switching and conduction performance. Key Specifications: 1200V | 50A | VCE(sat) 1.7V (typ). Its primary engineering benefits include reduced heatsink requirements and enhanced power density. This module's Trench/Fieldstop IGBT3 technology provides a well-calibrated balance between on-state and switching losses, making it an excellent fit for power conversion systems operating at frequencies up to the 20 kHz range.

Proven Performance in Demanding Power Topologies

The practical application of a power module reveals its true engineering value. The BSM50GD120DN2 has been integrated into numerous designs where operational economy and reliability are critical. For instance, in mid-power variable frequency drives (VFDs), its low-loss characteristics contribute directly to higher overall system efficiency. This allows for more compact drive designs, as the reduced heat dissipation lessens the dependency on bulky thermal management hardware. What is the impact of its Emitter Controlled diode? It results in softer switching, which reduces electromagnetic interference (EMI) and simplifies system-level filtering.

Meeting Tomorrow's Efficiency Mandates Today

As industrial and renewable energy sectors face increasingly stringent efficiency standards, the performance of core power components comes under scrutiny. The BSM50GD120DN2 is well-positioned to address these trends. Its inherent efficiency, a direct result of the Trench/Fieldstop IGBT3 technology, helps designers meet regulations for high-efficiency motors (IE4/IE5) and achieve higher energy ratings for solar inverters and uninterruptible power supplies (UPS). By minimizing wasted energy that would otherwise become heat, this module supports the development of more sustainable and cost-effective power electronic systems. For further insights into the backbone of modern power systems, explore our guide on IGBT modules and emerging technologies.

Inside the BSM50GD120DN2: A Focus on Loss Reduction

The performance of the BSM50GD120DN2 is fundamentally rooted in its advanced semiconductor technology. It incorporates Trench/Fieldstop IGBT3 chips, a mature technology renowned for its excellent trade-off between conduction and switching losses. The low collector-emitter saturation voltage (VCE(sat)) is a critical parameter for efficiency. Think of VCE(sat) as the pressure loss in a fully open water pipe; a lower value means less energy is wasted simply keeping the current flowing, translating directly to less heat and higher efficiency during the on-state.

Complementing the IGBTs is an Emitter Controlled 3 fast recovery diode. This diode is engineered for soft recovery characteristics, minimizing voltage overshoot and oscillation during turn-off. This dynamic performance not only reduces switching losses but also curtails the generation of high-frequency EMI, a significant benefit for simplifying filter design and ensuring electromagnetic compatibility (EMC). What is the benefit of its integrated NTC thermistor? It provides real-time temperature feedback, enabling precise thermal protection and system monitoring.

Core Specifications for System Evaluation

The following parameters are essential for evaluating the BSM50GD120DN2 in your power stage design. For a complete list of specifications and operating curves, please refer to the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Continuous Collector Current (Ic) @ Tc = 80°C | 50 A |

| Collector-Emitter Saturation Voltage (Vce(sat), typ) @ 50A | 1.70 V |

| Turn-On Switching Energy (Eon, typ) | 5.20 mJ |

| Turn-Off Switching Energy (Eoff, typ) | 5.80 mJ |

| Thermal Resistance, Junction to Case (RthJC) per IGBT | 0.36 K/W |

Download the BSM50GD120DN2 Datasheet for detailed technical information.

Optimized for High-Frequency Power Conversion

The balanced loss profile of the BSM50GD120DN2 makes it a versatile component for a range of power conversion applications. Its architecture is particularly effective in systems where efficiency and thermal stability are key design drivers.

- Motor Control & Drives: The module provides precise and efficient control for AC induction motors, permanent magnet motors, and servo drives, contributing to energy savings and reliable operation.

- Solar Power Inverters: In grid-tied and off-grid solar applications, its low switching losses help maximize the energy harvested from photovoltaic arrays by enabling higher inverter efficiency.

- Uninterruptible Power Supplies (UPS): The module's robust performance ensures dependable power delivery and high efficiency in online UPS systems, protecting critical loads.

- Welding Equipment: It can capably handle the demanding load cycles found in modern inverter-based welding power supplies.

For motor drives operating up to 20 kHz where minimizing heatsink size is paramount, the BSM50GD120DN2's 1.7V VCE(sat) makes it a superior selection over modules with higher conduction losses.

Data for Your Component Selection Process

To support your design evaluation, this section provides a factual comparison based on key datasheet parameters. This data is intended to empower your decision-making process by highlighting the performance trade-offs between related components. For systems requiring higher current handling, the related BSM75GD120DN2 offers an increased current rating within a similar package family.

| Feature | BSM50GD120DN2 | BSM75GD120DN2 |

|---|---|---|

| Continuous Collector Current (Ic) @ Tc=80°C | 50 A | 75 A |

| Vce(sat) (typ) @ Rated Ic | 1.70 V @ 50A | 1.75 V @ 75A |

| Package | EconoPACK™ 2 | EconoPACK™ 2 |

This comparison indicates that while both modules share the same voltage class and package, the primary differentiator is the current handling capability, with a marginal difference in typical saturation voltage at their respective nominal currents.

A Strategic Enabler for Next-Generation Power Systems

Selecting a power module is more than a line-item decision; it is a strategic choice that impacts system efficiency, thermal design, and long-term operating costs. The BSM50GD120DN2, with its foundation in proven Infineon IGBT3 technology, provides a clear pathway for developing power electronics that are not only powerful but also operationally economical. As the industry moves towards greater power density and electrification, leveraging components engineered for minimal energy loss will be a key factor in creating competitive and sustainable technologies. A deep understanding of how to interpret component data is crucial, and resources like this practical guide to decoding IGBT datasheets can provide a significant advantage.

Technical Inquiries on the BSM50GD120DN2

Below are answers to common questions engineers have when considering this IGBT module.

- What is the primary advantage of the Trench/Fieldstop IGBT3 technology in this module?

The main advantage is its optimized balance between low conduction losses (low VCE(sat)) and reduced switching losses. This combination allows for high efficiency across a broad range of operating frequencies, making it more versatile than technologies that excel in one area at the expense of the other. - Can the BSM50GD120DN2 be paralleled for higher current applications?

Yes, IGBT modules like the BSM50GD120DN2 can be paralleled. However, successful paralleling requires careful attention to gate drive circuit symmetry, busbar layout to ensure balanced current sharing, and thermal management. The positive temperature coefficient of VCE(sat) inherent in the IGBT3 technology helps in achieving stable current distribution among paralleled modules. - How does the integrated NTC thermistor aid in thermal protection?

The Negative Temperature Coefficient (NTC) thermistor provides an isolated, real-time temperature reading of the module's baseplate. This signal can be fed into the system's control logic to trigger alarms, reduce power (derating), or initiate a shutdown if the temperature exceeds safe limits, thus preventing catastrophic failure due to overheating. - What are the recommended gate driver voltage levels for the BSM50GD120DN2?

According to the datasheet, a gate-emitter voltage (VGE) of +15V is recommended for turning the IGBT on, while a range of -8V to -15V is typically used for a hard turn-off to ensure immunity against noise-induced turn-on. Always consult the official datasheet for precise gate drive conditions.