The Unsung Heroes of the Smart Grid: How IGBTs Power Modern HVDC Transmission

As our global energy landscape undergoes a seismic shift towards renewable sources and decentralized generation, the grid infrastructure that underpins it faces unprecedented challenges. Long-distance power transmission, grid stability with intermittent sources like wind and solar, and the need for efficient, controllable power flow are pushing traditional AC (Alternating Current) systems to their limits. This is where High-Voltage Direct Current (HVDC) transmission, specifically its modern iteration, becomes not just an alternative, but a necessity.

At the very heart of this technological revolution lies a power semiconductor device: the Insulated-Gate Bipolar Transistor (IGBT). For engineers and system designers working on the next generation of smart grids, understanding the pivotal role of IGBT modules in Voltage Source Converter (VSC) based HVDC systems is fundamental to building a resilient, efficient, and controllable energy future.

The Grid’s Growing Pains: Why Traditional AC Fails to Meet Modern Demands

For over a century, AC has been the undisputed champion of power transmission. However, its dominance is being challenged by the realities of the 21st-century energy mix. The primary pain points include:

- Integration of Renewables: Wind and solar farms are often located far from population centers (e.g., offshore or in remote deserts). Transmitting this power over long distances using AC results in significant resistive and reactive power losses, making it economically and technically inefficient.

- Grid Instability: The intermittent nature of renewables can introduce frequency and voltage fluctuations into the grid. AC systems, being synchronously interconnected, can propagate these disturbances, potentially leading to widespread instability or blackouts.

- Asynchronous Connections: Connecting separate AC grids that operate at different frequencies (e.g., connecting national grids) or are not phase-synchronized is impossible with a direct AC link. This limits power trading and mutual support between regions.

These limitations have created a clear demand for a more intelligent, manageable transmission technology—a role perfectly filled by flexible HVDC systems.

Enter VSC-HVDC: The Flexible Solution Powered by Power Electronics

While traditional HVDC systems (using Line-Commutated Converters or LCCs) have existed for decades, the game-changer has been the advent of Voltage Source Converter (VSC) technology. Unlike LCCs, which rely on the strength of the connected AC grid to operate, VSCs use self-commutated power semiconductor switches—predominantly IGBTs—to generate their own voltage waveform.

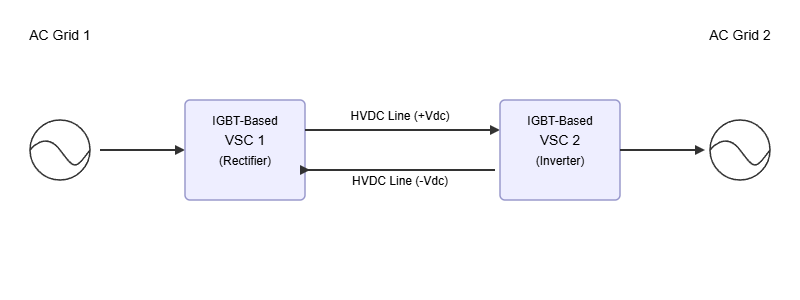

A VSC-HVDC link fundamentally consists of two converter stations connected by a pair of DC cables. Each station uses IGBTs to convert AC to DC (rectifier) or DC back to AC (inverter). This architecture gives VSC-HVDC its “flexible” moniker, offering capabilities that are simply unattainable with AC or LCC-HVDC technology.

The magic happens within the converter. By controlling the precise on/off switching of thousands of IGBTs using Pulse Width Modulation (PWM), a VSC can generate a clean, controllable AC voltage at its output, with full control over frequency, phase, and amplitude. This capability is the foundation of the smart grid, and the IGBT module is the linchpin that makes it all possible.

The Heart of the Converter: The Indispensable Role of IGBT Modules

IGBTs are not just simple switches in this context; they are the active elements that bestow VSC-HVDC systems with their transformative characteristics. Their role can be broken down into three critical functions.

Enabling Bidirectional Power Flow and Black Start Capability

Because IGBTs can be turned on and off at will via their gate terminal, a VSC can control both active (real) and reactive power independently and in either direction. This means a VSC station can not only transmit power but also act as a source of reactive power to support and stabilize the voltage of the connected AC grid, much like a synchronous condenser. Furthermore, this self-commutating ability allows a VSC to form its own AC voltage waveform without needing an existing grid. This is known as “black start” capability, a crucial feature for restoring power to a collapsed grid.

High-Frequency Switching for Superior Performance

Modern high-voltage IGBTs, such as the BSM300GA120DN2, are designed for fast and efficient switching. In VSC applications, they are typically switched at frequencies in the range of 1-2 kHz. This high-frequency PWM allows the converter to produce a near-perfect sinusoidal AC waveform. The immediate benefit is a dramatic reduction in harmonic distortion, which minimizes the need for the massive, expensive, and space-consuming AC filters required in older LCC-HVDC systems. This results in a smaller station footprint and lower capital costs.

Enhancing Grid Stability and Resilience

The rapid control response of IGBTs allows a VSC-HVDC system to react almost instantaneously to grid disturbances. If a fault occurs or a large load is suddenly connected, the VSC can inject or absorb reactive power within milliseconds to stabilize the voltage. It can also actively damp power oscillations between different parts of the grid. This function is indispensable for grids with a high penetration of fluctuating renewable energy, ensuring the lights stay on even when the wind stops blowing or clouds cover the sun.

Selecting the Right IGBT for VSC-HVDC: A Practical Guide for Engineers

The extreme demands of grid-level applications mean that not just any IGBT will suffice. Selecting the correct module is a complex engineering decision that balances performance, cost, and long-term reliability. For a comprehensive understanding, it’s always recommended to study how to decode IGBT datasheets thoroughly. The most common topology in modern VSC-HVDC is the Modular Multilevel Converter (MMC), which connects hundreds of smaller sub-modules in series to achieve the required high voltage.

Here’s a breakdown of the key parameters engineers must scrutinize:

Key Parameter Deep Dive

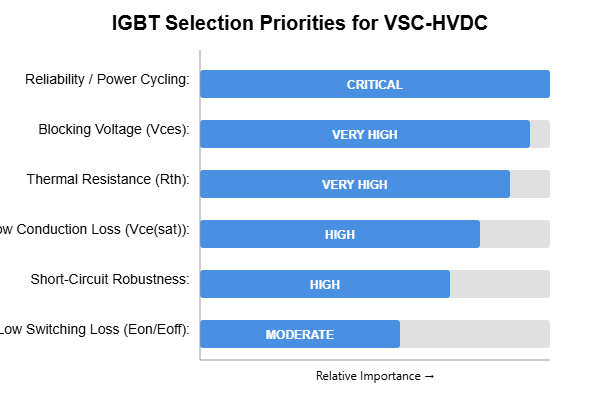

- Voltage Rating (Vces): This is the first and most critical parameter. In MMC topologies, IGBTs with voltage ratings of 3.3 kV, 4.5 kV, and even 6.5 kV are common. Higher blocking voltages mean fewer modules are needed in series, simplifying the converter design. However, this must be balanced against the higher conduction losses (Vce(sat)) typically associated with higher voltage devices.

- Current Rating & Thermal Performance (Rth): The IGBT must handle enormous continuous and peak currents. Just as important is its ability to dissipate the resulting heat. The thermal resistance from junction to case (Rth(j-c)) is a critical datasheet value. Lower Rth indicates better heat transfer, leading to a lower operating junction temperature and, consequently, higher reliability and longer service life. Advanced packaging, like those used in Infineon PrimePACK™ modules, is designed specifically for this challenge.

- Switching Characteristics (Eon, Eoff, Vce(sat)): This is the classic engineering trade-off. Low saturation voltage (Vce(sat)) reduces conduction losses, which are dominant in high-current applications. However, IGBTs optimized for low Vce(sat) often have higher switching losses (Eon and Eoff). In the 1-2 kHz range of VSC-HVDC, both loss components are significant, so a balanced device is often optimal.

- Reliability and Power Cycling Capability: Grid infrastructure is expected to operate reliably for 25-30 years. IGBTs in a VSC are subjected to constant thermal and power cycles. The module’s ability to withstand these stresses without degradation (e.g., bond wire lift-off or solder fatigue) is paramount. This is where Power Cycling Capability curves in the datasheet become essential for lifetime estimation.

| Parameter | Importance in VSC-HVDC | Engineering Consideration |

|---|---|---|

| Blocking Voltage (Vces) | Extremely High | Select high-voltage devices (3.3kV-6.5kV) to minimize series connections and complexity. Must include a significant safety margin. |

| Conduction Loss (Vce(sat)) | Very High | Dominant loss factor. Lower Vce(sat) directly improves system efficiency and reduces cooling requirements. |

| Switching Losses (Eon/Eoff) | High | Significant at typical MMC frequencies. A balance with Vce(sat) is crucial for overall thermal management. |

| Thermal Resistance (Rth) | Extremely High | Lower Rth is critical for reliability. Determines the effectiveness of the cooling system and the module’s lifetime. |

| Short-Circuit Withstand Time | High | Must be long enough for protection circuits to detect a fault and safely shut down the device (typically ≥ 10 µs). |

| Power Cycling Capability | Extremely High | Defines the module’s mechanical and thermal ruggedness over a long service life. Critical for grid-tied systems. |

Case Study: Offshore Wind Farm Integration via VSC-HVDC Link

Problem: A new 1 GW offshore wind farm is situated 150 km from the coast. Transmitting this power via a subsea AC cable is unfeasible due to high capacitive charging currents and voltage control issues, leading to unacceptable losses and instability.

Solution: A symmetric monopole VSC-HVDC system is chosen. The offshore converter station collects power from the wind turbines, converts it to ±320 kV DC, and transmits it to an onshore station. The system is built using an MMC topology with press-pack high-voltage IGBTs rated at 4.5 kV. These press-pack designs offer excellent thermal performance and cosmic ray resilience, which are crucial for grid applications. The selection of a robust module, conceptually similar to high-power devices like the FZ1600R12KF4_S1, ensures high reliability.

Result:

- Total transmission losses are under 3%, a reduction of over 30% compared to the projected AC alternative.

- The onshore VSC station provides 250 Mvar of dynamic reactive power support to the grid, strengthening voltage stability in the region.

- During a regional grid disturbance, the VSC-HVDC link successfully “islanded” the wind farm and performed a seamless reconnection once the grid was stable, preventing damage to the turbines and demonstrating its powerful control capabilities.

Future Trends and Conclusion: The Road to a More Resilient Grid

The development of IGBTs for HVDC applications is far from over. We are seeing a clear trend toward even higher blocking voltages, with 8kV and 10kV devices on the horizon. This will further simplify converter designs and boost efficiency. Innovations in packaging technology, such as double-sided cooling and advanced sintering techniques, are pushing the boundaries of power density and reliability. While Wide Bandgap (WBG) materials like Silicon Carbide (SiC) show promise, their current cost and maturity level make high-power IGBTs, like the CM600HU-24F, the undisputed workhorse for VSC-HVDC for the foreseeable future.

In conclusion, the IGBT module is the fundamental enabling technology that has transformed HVDC from a niche solution for point-to-point power transfer into the flexible, intelligent backbone of the modern smart grid. Its ability to provide precise, high-speed control over power flow is what allows us to build a more stable, efficient, and resilient grid capable of accommodating the energy sources of tomorrow.

For engineers designing these critical systems, the selection of high-reliability IGBT modules is not just a component choice—it’s an investment in the stability of our future energy infrastructure. To ensure your designs meet the rigorous demands of grid-level applications, explore our comprehensive range of high-power IGBTs and power modules today.