The Unseen Costs of a Millisecond Delay: Why Mechanical Breakers Are Hitting Their Limit

For over a century, the electromechanical circuit breaker has been the silent, dutiful guardian of our electrical systems. From residential homes to sprawling industrial plants, its characteristic “clunk” has signified safety and protection. Yet, in the age of high-frequency power electronics, DC microgrids, and billion-dollar data centers, that familiar sound is becoming a signal of a technology reaching its operational ceiling. The core limitation isn’t a lack of power, but a lack of speed. A mechanical breaker’s reaction time, measured in tens of milliseconds, is an eternity for modern semiconductors.

This delay, driven by physical inertia and the time required to quench a dangerous electric arc, creates significant vulnerabilities. An unmitigated fault current can wreak havoc in the microseconds before a mechanical contact even begins to move. This can lead to catastrophic failures in sensitive electronics, costly downtime in automated facilities, and severe safety hazards like arc flash events. Furthermore, every trip causes physical wear on the contacts, leading to a finite lifespan and the need for regular, often costly, maintenance. As systems demand faster, more reliable, and more intelligent protection, the industry is turning to a solution with no moving parts: the Solid-State Circuit Breaker (SSCB).

The Dawn of Instantaneous Protection: Understanding the Solid-State Circuit Breaker (SSCB)

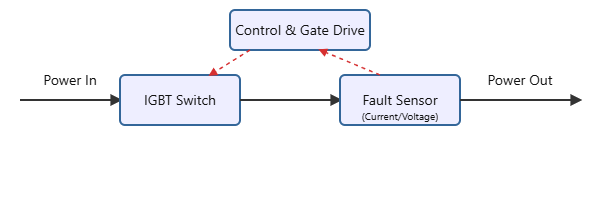

A Solid-State Circuit Breaker performs the same fundamental task as its mechanical predecessor—interrupting the flow of current during a fault—but it does so with the speed of light, not the speed of mechanics. Instead of physically separating metal contacts, an SSCB uses power semiconductors to stop the flow of electrons. The heart of this modern protector is typically an Insulated Gate Bipolar Transistor (IGBT).

Think of an IGBT as an incredibly fast and robust digital valve for electricity. By applying a small voltage to its “gate” terminal, a control circuit can turn the flow of thousands of amperes on or off in under a microsecond. In an SSCB, a sophisticated sensing circuit continuously monitors the current. The instant a fault (like a short circuit) is detected, the controller removes the voltage from the IGBT’s gate, effectively closing the valve and interrupting the circuit. This entire process happens without an electric arc, without mechanical wear, and at a speed that can protect even the most sensitive downstream components.

Mechanical vs. IGBT-Based SSCB: A Head-to-Head Technical Comparison

When engineers evaluate the shift from traditional to solid-state protection, the differences are stark. While mechanical breakers have a long-established history, IGBT-based SSCBs offer a suite of performance advantages that are becoming non-negotiable in critical applications. The decision involves weighing initial cost against long-term reliability, speed, and total cost of ownership (TCO).

| Parameter | Traditional Mechanical Breaker | IGBT-Based Solid-State Breaker (SSCB) |

|---|---|---|

| Response Time | Slow (20 – 100 milliseconds) | Ultra-Fast (< 1 – 10 microseconds) |

| Lifespan & Reliability | Limited by mechanical wear and arc erosion (thousands of cycles) | Extremely high; no moving parts to wear out (millions of cycles) |

| Arcing | Generates a significant, dangerous electric arc upon tripping | Inherently arc-less operation |

| Conduction Losses | Very low (milliohms of contact resistance) | Higher, due to the IGBT’s on-state voltage drop (Vce(sat)) |

| Control & Intelligence | Limited; purely a protection device | Highly programmable (adjustable trip points, soft start, communication) |

| Size & Weight | Bulky and heavy, especially at high currents | More compact and lightweight |

| Initial Cost | Low | High |

The Core Enabler: Why the IGBT is the Ideal Switch for Modern SSCBs

The success of an SSCB hinges entirely on the performance of its semiconductor switch, and the IGBT stands out as the workhorse for most high-power applications. While MOSFETs are excellent for lower voltages and SiC/GaN devices offer superior performance at a premium, IGBTs hit the sweet spot of power, speed, and cost-effectiveness.

Key IGBT characteristics that make them ideal for SSCBs include:

- High Power Density: IGBTs can block high voltages (e.g., 1200V, 1700V) while conducting hundreds or even thousands of amperes, making them suitable for industrial-scale protection.

- Fast, Controllable Switching: The voltage-controlled gate allows for simple and fast switching with relatively low power consumption from the control circuitry.

- Exceptional Ruggedness: A critical parameter for a breaker is its Short-Circuit Withstand Time. IGBTs are specifically designed to survive direct short-circuit conditions for several microseconds, giving the control circuit ample time to detect the fault and safely turn the device off. Modules like the Mitsubishi CM600DX-24T are engineered with robust SOA (Safe Operating Area) characteristics for exactly these types of high-stress events.

- Mature Technology: Decades of development in applications like Variable Frequency Drives (VFDs) and solar inverters have made IGBTs a reliable, well-understood, and cost-effective technology.

Overcoming the Hurdles: Key Design Challenges in IGBT-Based SSCBs

While the advantages are compelling, designing an effective IGBT-based SSCB is not a simple drop-in replacement. Engineers must address several critical challenges to ensure robust and reliable operation.

- Conduction Losses and Thermal Management: This is the primary drawback of an SSCB. An IGBT has a forward voltage drop (Vce(sat)) that, while small, is significantly higher than a mechanical contact. This drop generates heat (Power Loss = Vce(sat) * Current). Effective thermal management, including properly sized heatsinks and potentially fan cooling, is essential to keep the IGBT within its safe operating temperature.

- Overvoltage from Inductive Loads: When an SSCB interrupts current flowing to an inductive load (like a motor), the collapsing magnetic field can induce a massive voltage spike across the IGBT. This can easily exceed the IGBT’s breakdown voltage and destroy it. This is managed using protection circuits like snubber circuits or active clamping implemented in the gate drive.

- Robust Gate Drive Design: The gate driver is the brain that tells the IGBT muscle what to do. It must be capable of providing strong, clean turn-on and turn-off signals to minimize switching losses. It also needs to be resilient to noise and provide protection features like undervoltage lockout (UVLO) and fast fault detection. For an in-depth look, consider these 5 practical tips for robust IGBT gate drive design.

- Cost-Effectiveness: The bill of materials for an SSCB—including the IGBT module, gate driver, controller, and thermal solution—is currently higher than for a comparable mechanical breaker. However, as IGBT prices fall and the cost of downtime and arc flash mitigation rises, the total cost of ownership for SSCBs is becoming increasingly favorable.

The Future is Solid-State: Market Trends and the Road to 2025 and Beyond

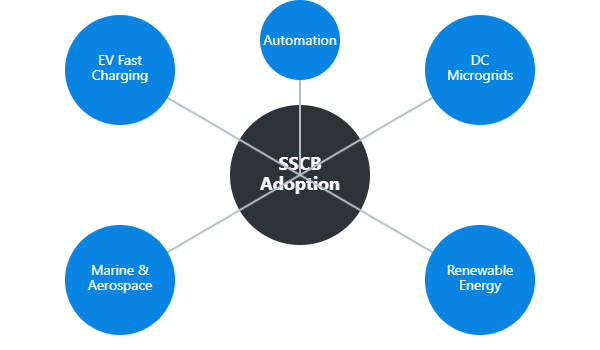

The transition to solid-state protection is no longer a question of “if,” but “when.” Several key industry trends are accelerating the adoption of IGBT-based SSCBs, pushing them from niche applications into the mainstream by 2025 and beyond.

- The Rise of DC Power: The proliferation of DC microgrids, data centers, and battery energy storage systems (BESS) creates a critical need for fast, reliable DC protection, a domain where mechanical breakers struggle with arc quenching.

- Electric Vehicle (EV) Revolution: The high-voltage DC systems in EVs and their ultra-fast charging infrastructure require microsecond-level protection to ensure the safety of batteries and power electronics. The core of an EV inverter relies on the same power switching principles.

- Renewable Energy Integration: Protecting solar inverters and wind turbine converters from grid faults and internal shorts is vital for uptime and equipment longevity. SSCBs can isolate faults without the downtime associated with replacing fuses or resetting breakers.

- Automation and Industry 4.0: In fully automated factories, any downtime is catastrophic. The “set and forget” reliability of an SSCB, with its diagnostic capabilities, is a perfect fit for smart manufacturing.

Your Engineering Checklist for the Transition

As you consider migrating from mechanical to solid-state protection, the benefits of speed, reliability, and control are clear. An SSCB is not just a breaker; it’s an intelligent power management device. For engineers designing next-generation systems, the shift is becoming a strategic necessity.

Here are the key takeaways:

- Evaluate the True Cost of Failure: Don’t just compare the initial price of the breaker. Factor in the cost of downtime, equipment damage, and safety risks associated with slower mechanical protection.

- Prioritize Speed Where It Matters: For any system with sensitive power electronics (drives, inverters, servers), the microsecond response time of an SSCB is a system-level insurance policy.

- Focus on Thermal Design: The number one challenge is managing heat from conduction losses. Invest time in proper thermal simulation and heatsink selection.

- Select the Right IGBT: Look beyond just voltage and current ratings. Scrutinize the Safe Operating Area (SOA), short-circuit withstand time, and thermal resistance data. High-performance modules like the Infineon FF450R12KE4 are designed with these parameters in mind.

The era of the purely mechanical breaker is drawing to a close in high-performance applications. The future of electrical protection is fast, intelligent, and solid-state. If you are designing systems that demand the highest levels of safety and uptime, exploring IGBT-based SSCB technology is a critical step forward. For help selecting the right IGBT modules for your next-generation protection circuits, reach out to our application specialists for expert guidance.