Content last revised on January 22, 2026

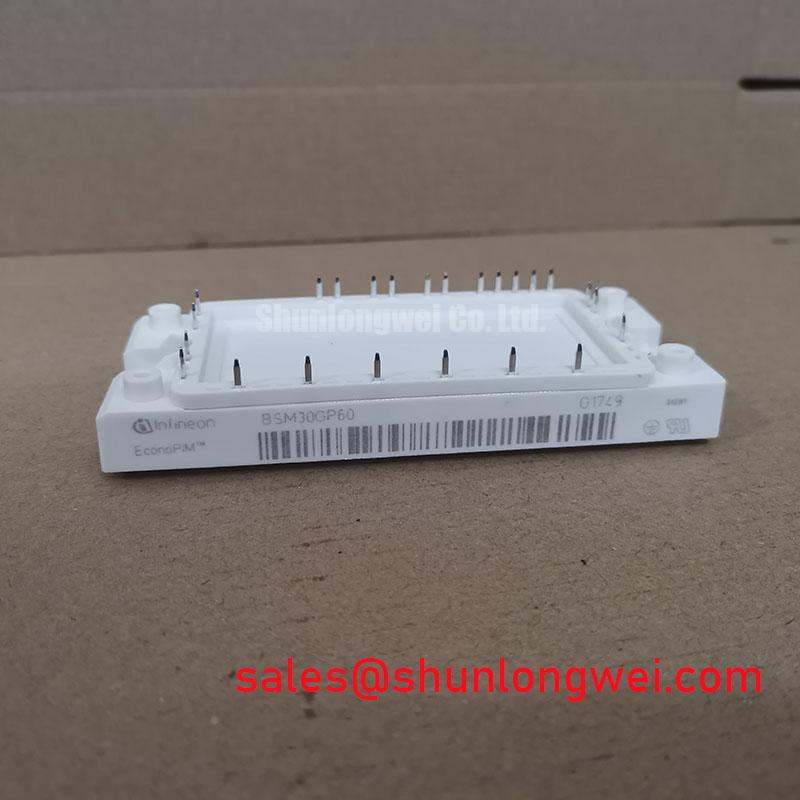

BSM30GP60: 600V Integrated IGBT Module for Compact Drives

Streamlining Power Stage Design with an All-in-One Solution

The Infineon BSM30GP60 is a Power Integrated Module (PIM) designed to accelerate the development of compact power conversion systems by integrating key components into a single housing. Its value lies in offering a complete power stage solution for low-power motor drives and inverters. With core specifications of 600V | 30A (Inverter) | 15A (Brake-Chopper), this module provides significant design simplification and enhanced system reliability. The key benefits include a drastically reduced component count and built-in thermal monitoring. For engineers wondering how to shrink their drive's footprint without complicating the design, the BSM30GP60's integration of a three-phase rectifier, inverter, and brake chopper provides a direct answer by minimizing external circuitry and simplifying assembly.

Technical Deep Dive

Inside the BSM30GP60: A Blueprint for System Simplification

The BSM30GP60 is architected as a highly integrated power core. The internal topology combines three distinct power stages within one EconoPIM™ 2 package, a design choice that directly supports system miniaturization and manufacturing efficiency. The module contains a full three-phase uncontrolled rectifier for AC-to-DC conversion, a three-phase IGBT bridge inverter for DC-to-AC power delivery, and an IGBT brake chopper for managing regenerative energy. What is the primary benefit of this integrated approach? It fundamentally reduces the physical space and complexity required compared to a discrete solution, eliminating the need for multiple component sourcing and complex power interconnects on the PCB.

Furthermore, an integrated NTC thermistor is included, positioned to provide accurate feedback on the module's operating temperature. This built-in sensor simplifies the implementation of crucial thermal protection mechanisms, allowing the control system to monitor temperature directly without needing external sensors. This integration is a key enabler for building dependable, power-dense systems where thermal management is a critical design constraint. For more details on the importance of thermal performance, explore our guide on unlocking IGBT thermal performance.

Success Stories / Deployment Snippets

From Concept to Compact Drive: A BSM30GP60 Integration Snapshot

A typical deployment scenario for the BSM30GP60 involves a manufacturer of decentralized automation components, such as motor-integrated servo drives or compact conveyor belt controllers. In one such case, a design team was tasked with reducing the overall volume of their next-generation variable frequency drive (VFD) by 30% to fit within a smaller machine chassis. Their existing design used separate rectifier, inverter, and braking resistor control circuits.

By replacing these discrete stages with a single BSM30GP60 module, the engineering team immediately reclaimed significant PCB real estate. The unified housing simplified the heatsink design, as only one component needed to be mounted. The integrated NTC thermistor eliminated a separate sensor and its associated wiring, further streamlining the assembly process. The result was a final product that not only met the size reduction target but also had a lower assembly time and a simplified bill of materials, directly contributing to a more competitive total cost of ownership.

Intra-Series Comparison & Positioning

Positioning the BSM30GP60: The Go-To Module for Integrated Low-Power Drives

Within the broader landscape of IGBT Modules, the BSM30GP60 carves out a specific niche. It is not designed for high-power applications requiring hundreds of amps, but rather for systems where integration, space, and ease-of-use are the primary drivers. Compared to discrete IGBTs or simpler half-bridge modules, its value proposition is the reduction of design complexity. For systems where a more powerful brake chopper is needed, the related BSM50GP60 offers a higher current rating within a similar integrated framework.

For low-power AC motor drives and servo applications under approximately 11 kW, the BSM30GP60's all-in-one configuration presents a compelling case. Its collector-emitter voltage of 600V makes it suitable for 200/240V AC line applications. The data-driven best fit for this module is in compact VFDs for material handling or HVAC systems where the integration of the input rectifier and brake chopper simplifies the power stage into a single, reliable building block.

Key Parameter Overview

Core Specifications for Streamlined Integration

The technical specifications of the BSM30GP60 are tailored for efficiency and reliability in integrated power systems. The parameters below are central to its role in simplifying the design of compact motor drives. For a complete list of specifications, please download the official datasheet.

| Parameter | Value | Conditions |

|---|---|---|

| Collector-Emitter Voltage (VCES) - Inverter & Chopper | 600 V | Tvj = 25°C |

| DC Collector Current (IC) - Inverter | 30 A | TC = 80°C |

| DC Collector Current (IC) - Brake-Chopper | 15 A | TC = 80°C |

| DC Forward Current (ID) - Rectifier | 30 A | TC = 80°C |

| Collector-Emitter Saturation Voltage (VCEsat) - Inverter | 1.95 V (Typ.) | IC = 30 A, Tvj = 25°C |

| NTC Resistance (R25) | 5 kΩ | TC = 25°C |

Application Scenarios & Value

Enabling High-Density Power Conversion in Compact Systems

The integrated architecture of the BSM30GP60 delivers tangible value across several key application areas where space and manufacturing simplicity are paramount. Its design directly addresses the challenges faced by engineers developing modern, compact power electronics.

- Compact Variable Frequency Drives (VFDs): In small VFDs used for pumps, fans, and conveyors, the module's all-in-one nature drastically shrinks the power stage footprint. The thermal resistance of the module acts like the diameter of a pipe for heat—a lower value means heat can be extracted more efficiently. The BSM30GP60's specified thermal characteristics ensure effective heat transfer to a heatsink, which is critical in tightly packed enclosures.

- Decentralized Servo Drives: For robotic arms and automation systems where drives are located near the motor, minimizing size and weight is essential. The BSM30GP60 provides the complete power conversion function in a single component, reducing complexity and potential points of failure. This contributes to the reliability needed in precision robotic servo drives.

- Small Uninterruptible Power Supplies (UPS): In compact UPS systems, the module can serve as the core of the power conversion stage, handling both battery charging (via the rectifier) and inverter output. The integrated brake chopper circuit can be repurposed for managing DC bus voltage, showcasing the module's versatility.

Industry Insights & Strategic Advantage

Aligning with Industry 4.0: The Value of Integrated Power Stages

The move toward smarter, more connected manufacturing environments—often termed Industry 4.0—places new demands on component design. There is a growing need for machinery that is more compact, more energy-efficient, and faster to deploy. Power Integrated Modules like the BSM30GP60 are strategically positioned to meet these needs. By consolidating multiple functions, these modules reduce the number of components to be sourced, stocked, and assembled, streamlining the supply chain.

This simplification is not merely a matter of convenience; it translates into a strategic advantage. Reduced assembly complexity leads to higher manufacturing yields and improved reliability. Furthermore, the smaller physical footprint enabled by such integration allows for the development of more modular and decentralized automation systems. As factories become more automated and adaptable, the ability to deploy compact, reliable motor control solutions quickly becomes a key competitive differentiator, a trend that highly integrated modules are well-suited to support. To understand more about the building blocks of these systems, refer to our foundational guide on IGBT modules.

Design and Integration Outlook

Looking ahead, the trajectory for power electronics in industrial automation and motion control is clear: greater functional density, improved thermal performance, and simplified system design. The BSM30GP60 represents a crucial step on this path for low-power applications. For design engineers, the strategic adoption of such integrated modules allows for a shift in focus from the intricacies of power stage layout and component matching to the higher-level challenges of control algorithm optimization and system connectivity. Future design cycles will likely see even greater integration, but for current-generation compact drives, the BSM30GP60 provides a proven, efficient foundation for building smaller, more reliable, and cost-effective systems.