Content last revised on January 13, 2026

Infineon FF1200R17KP4_B2 | Robust 1700V/1200A IGBT for High-Power Converters

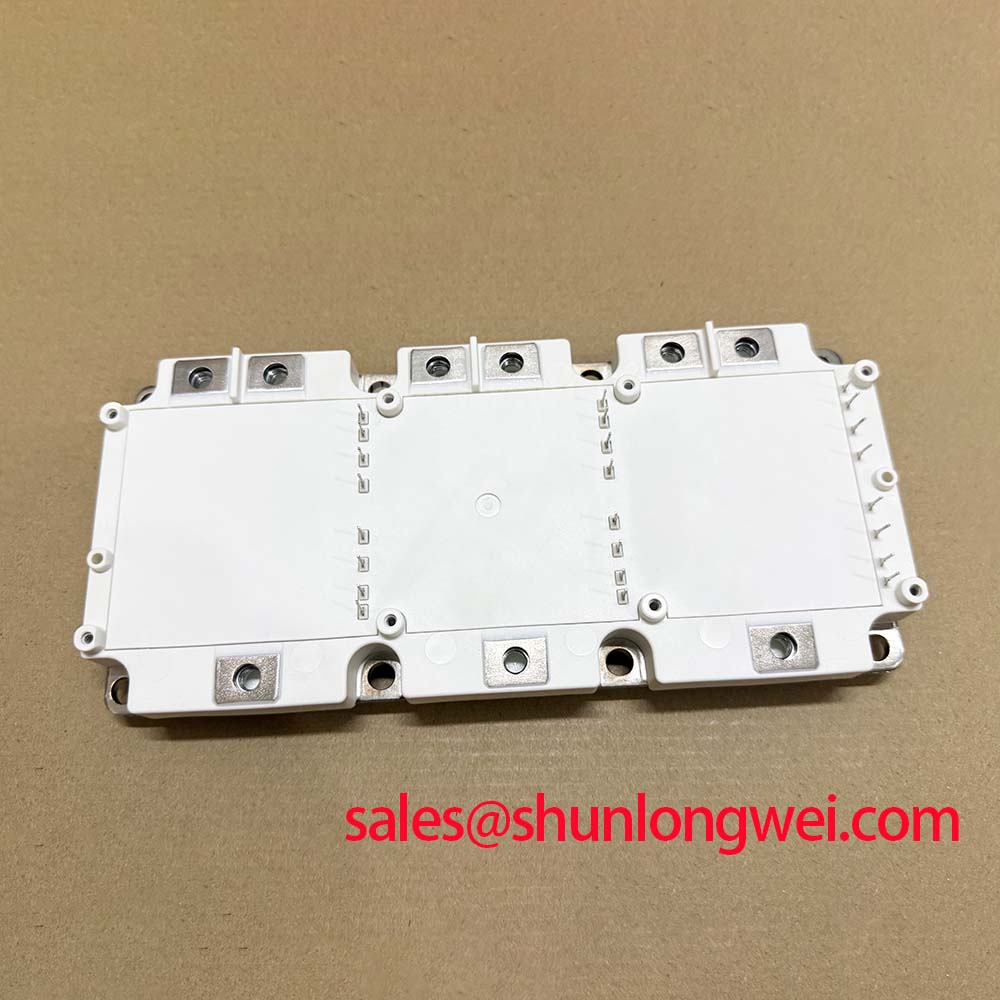

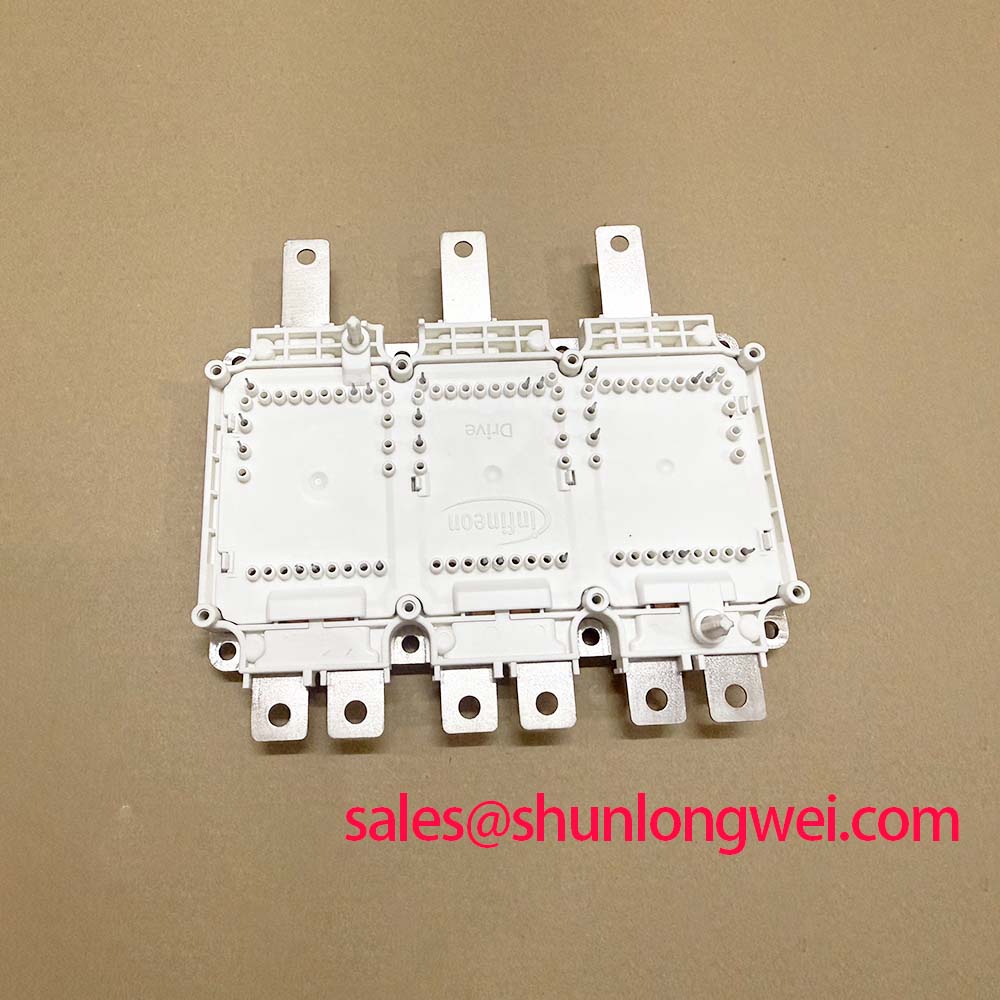

The Infineon FF1200R17KP4_B2 is a high-power IGBT module engineered for reliability and efficiency in the most demanding power conversion applications. As a cornerstone component for systems operating in the megawatt class, this module combines a formidable 1700V blocking voltage with a 1200A current rating, all built upon Infineon's proven and mature technology platforms. It represents a go-to solution for engineers developing high-reliability inverters and converters where performance cannot be compromised.

Product Highlights Overview

The FF1200R17KP4_B2 is not just a collection of specifications; it's a carefully engineered solution designed to solve critical challenges in high-power electronics. Its value is rooted in a combination of electrical robustness, thermal efficiency, and mechanical stability.

- High Voltage & Current Rating: With 1700V and 1200A capability, this module provides substantial design margin for systems connected to 690V AC lines and beyond.

- Optimized Switching Performance: Leveraging Infineon's TRENCHSTOP™ IGBT4 technology, it strikes an engineered balance between low conduction losses (VCE(sat)) and manageable switching losses.

- Exceptional Robustness: Housed in the industry-standard IHV B-series package, it ensures excellent thermal cycling capability and a high short-circuit withstand time, critical for long-term operational reliability.

- Proven Application Fit: Ideally suited for high-power industrial drives, renewable energy converters (wind and solar), and grid infrastructure applications.

Technical Deep Dive: TRENCHSTOP™ IGBT4 and IHV Package Synergy

At the heart of the Infineon FF1200R17KP4_B2 lies the TRENCHSTOP™ IGBT4 chip technology. This represents a mature and highly optimized generation of IGBTs. The "Trench" structure creates a vertical gate, allowing for a higher channel density on the silicon. This directly results in a lower on-state voltage drop, or VCE(sat), which is the primary source of conduction losses. For high-current applications like motor drives, this reduction in VCE(sat) translates directly into lower heat generation and higher overall system efficiency.

This advanced silicon is housed in a robust IHV (IHM-B) package, a crucial element of its performance. The package's design focuses on superior thermal management by featuring an isolated copper baseplate that facilitates a very low thermal resistance path to the heatsink. This efficient heat extraction is vital for maintaining the IGBT's junction temperature within safe operating limits, especially under heavy load cycles. The combination of efficient silicon and a thermally proficient package makes the FF1200R17KP4_B2 a dependable workhorse for systems requiring both high power and long service life.

Application Scenarios & Value Proposition

The specific characteristics of this IGBT module make it an ideal choice for several key high-power sectors:

- Wind Turbine Converters: The 1700V rating is perfectly suited for the grid-side converters in multi-megawatt wind turbines. Its proven reliability and robust thermal performance are essential for minimizing downtime and maintenance costs in these often remote and harsh environments.

- High-Power Industrial Motor Drives: In applications like mining conveyors, large pumps, and industrial compressors, the module's ability to handle 1200A provides the necessary torque control for massive induction motors, while its efficiency helps reduce the plant's overall energy consumption.

- Grid Infrastructure & UPS: For STATCOMs, large-scale uninterruptible power supplies (UPS), and other grid-support systems, the FF1200R17KP4_B2 delivers the raw power handling and reliability required to ensure power quality and grid stability.

Key Parameter Overview

For engineers requiring quick access to critical data, the table below summarizes the core specifications. For a complete dataset, please download the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 1700 V |

| Continuous Collector Current (I_C) @ T_C = 80°C | 1200 A |

| Collector-Emitter Saturation Voltage (V_CE,sat) @ I_C = 1200A, T_vj = 125°C | 2.45 V (Typ.) |

| Total Switching Energy (E_tot) @ I_C = 1200A, T_vj = 125°C | 290 mJ (Typ.) |

| Short-Circuit Withstand Time (t_sc) | 10 µs |

| Maximum Operating Junction Temperature (T_vj op) | 150 °C |

Frequently Asked Questions (FAQ)

What are the critical considerations for the gate drive design for the FF1200R17KP4_B2?

Given its high current rating and large gate capacitance, a robust gate drive is paramount. We recommend a drive capable of sourcing and sinking at least 15-20A peak current to ensure fast and controlled switching. Employing a negative gate voltage (e.g., -8V to -15V) during the off-state is highly advisable to prevent parasitic turn-on induced by dV/dt, especially in a half-bridge configuration. Furthermore, using the integrated Kelvin emitter connection for the gate driver return path is essential to bypass stray inductance from the main power terminals, ensuring clean and reliable gate control.

How can system reliability be maximized when using this module?

Maximizing reliability involves a multi-faceted approach. First, prioritize excellent thermal management with a low Rth heatsink and a high-quality thermal interface material (TIM) applied correctly. Second, implement comprehensive protection circuits for over-current, over-voltage, and over-temperature scenarios. Finally, ensure the mechanical mounting is secure and follows the torque specifications in the datasheet to guarantee optimal thermal contact and prevent long-term mechanical stress. For further design support or to discuss your specific application, please contact our technical team.