Infineon FP30R06YE3 | A Compact Powerhouse for Low-Power Motor Drives

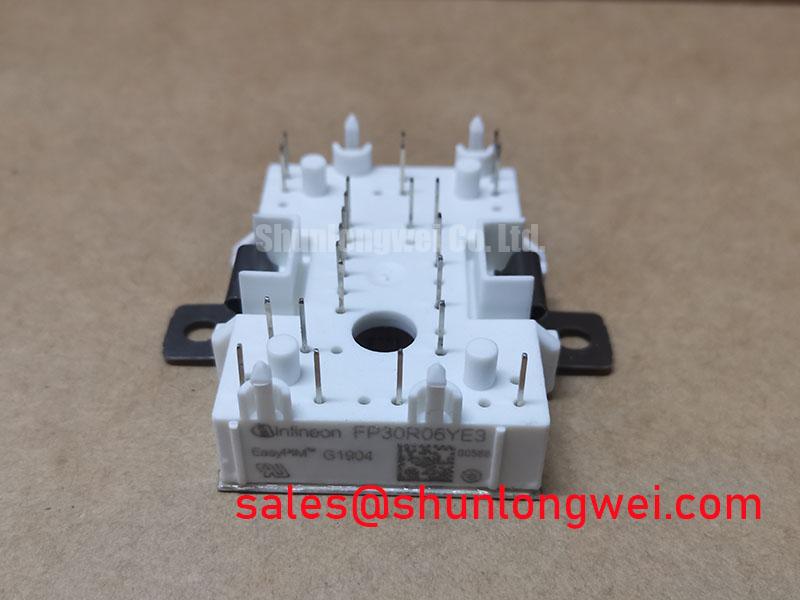

The Infineon FP30R06YE3 is an expertly engineered Power Integrated Module (PIM) that provides a robust, all-in-one solution for low-power motion control applications. Housed in the industry-proven EasyPACK™ 1B package, this IGBT module integrates a three-phase input rectifier, a brake chopper, and a three-phase inverter stage into a single, compact footprint. This high level of integration is not just about saving space; it's about simplifying design, reducing assembly complexity, and accelerating time-to-market for your next project.

- System Simplification: Consolidates multiple power stages, significantly reducing the bill of materials (BOM) and PCB layout complexity.

- Optimized Performance: Leverages Infineon's reliable TRENCHSTOP™ IGBT3 technology to achieve an excellent trade-off between conduction and switching losses.

- Enhanced Reliability: Features an integrated NTC thermistor for precise, real-time temperature monitoring, enabling robust thermal protection schemes.

- Mechanical Integrity: The EasyPACK™ package with PressFIT pins ensures a reliable, solder-free mounting process, improving manufacturing yield and long-term durability.

Application Scenarios & Value Proposition

The FP30R06YE3 is not a general-purpose component; it is a specialized tool designed to excel in specific, demanding environments. Its architecture directly addresses the core challenges faced by engineers in modern power conversion.

Precision Servo Drives

In robotics and factory automation, response time and positional accuracy are paramount. The FP30R06YE3's integrated brake chopper is critical for managing regenerative energy during rapid deceleration cycles. This allows for tighter control loops and protects the DC bus from overvoltage conditions, ensuring the precise and reliable operation essential for high-performance servo drives.

HVAC and Pump Systems

Energy efficiency is the primary driver in building automation. This module's use of TRENCHSTOP™ IGBT3 technology results in a low saturation voltage (VCE(sat)), minimizing conduction losses. For variable-speed fans and pumps that operate for extended periods, this directly translates into lower energy consumption, reduced operating costs, and compliance with stringent efficiency standards.

General-Purpose Inverters

For designers of compact inverters up to ~10 kW, the FP30R06YE3 offers a streamlined path from concept to production. By integrating the input rectifier and inverter stage, it eliminates the need for sourcing and qualifying separate components, simplifying thermal management and mechanical assembly. This makes it an ideal workhorse for conveyor belts, mixers, and other small industrial machinery.

Technical Deep Dive: The Engineering Behind the Performance

Engineered for Low Conduction Losses: TRENCHSTOP™ IGBT3

At the heart of this module is Infineon's TRENCHSTOP™ IGBT3 technology. This established chip generation is specifically optimized for low-frequency switching applications (typically below 16 kHz), which are common in motor drives. The technology provides a very low VCE(sat), which is the dominant loss factor in these applications. The direct engineering benefit is reduced heat generation, allowing for a smaller, more cost-effective heatsink and improving the overall reliability of the end system by reducing thermal stress. For a deeper understanding of thermal issues, explore our guide on preventing IGBT failure.

Integrated Thermal Monitoring: The NTC Advantage

Effective thermal management is non-negotiable for power electronics. The FP30R06YE3 includes an on-board NTC thermistor strategically placed to provide an accurate reading of the module's baseplate temperature. This allows the system's controller to implement intelligent thermal management, such as derating power or triggering a controlled shutdown before a catastrophic failure occurs. This built-in feedback mechanism is a cornerstone of a robust and durable design.

Key Parameter Overview

The following table outlines the critical performance specifications for the Infineon FP30R06YE3. For a comprehensive list of parameters and operating characteristics, it is essential to consult the official product datasheet. You can access it here: Download the FP30R06YE3 Datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 600 V |

| Nominal Collector Current (I_C nom) | 30 A |

| V_CE(sat) (Typ. at I_C nom, T_vj=25°C) | 1.50 V |

| Topology / Configuration | PIM (Rectifier + Brake + Inverter) |

| Integrated Features | NTC Thermistor |

| Package | EasyPACK™ 1B |

Frequently Asked Questions (FAQ)

1. What are the key considerations for the gate drive circuit for the FP30R06YE3?

Given its target applications in potentially noisy industrial environments, a robust gate drive is crucial. We recommend using a dedicated gate driver IC that provides a stable +/- 15V supply. To prevent parasitic turn-on caused by dV/dt, a negative turn-off voltage (e.g., -5V to -8V) is highly advisable. Furthermore, keep the gate drive traces on the PCB as short and direct as possible to minimize stray inductance. For more in-depth guidance, review these 5 practical tips for robust gate drive design.

2. Is this PIM module suitable for paralleling to achieve higher power output?

No, the FP30R06YE3 is a PIM (Power Integrated Module) designed for standalone operation in its specified power class. Its internal layout and pin structure are not optimized for current sharing between multiple modules. Attempting to parallel these devices would likely lead to severe current imbalance and premature failure. For applications requiring higher current, engineers should select a single, appropriately rated IGBT module from a higher power family.

If you have further questions or require design assistance for your specific application, please do not hesitate to contact our technical team for expert support.