Content last revised on January 25, 2026

SKiM304GD12T4D: Engineering Analysis of a 1200V Six-Pack IGBT Module for High-Reliability Drives

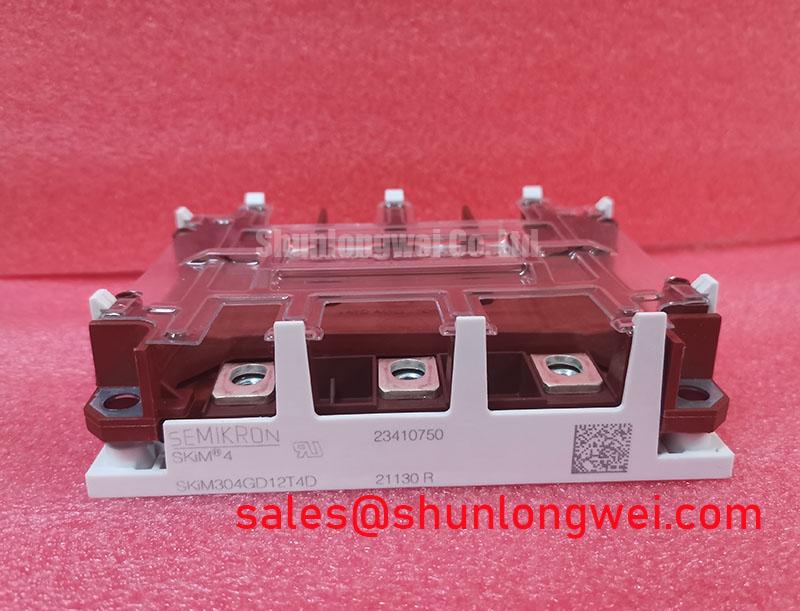

An In-depth Look at the SKiM304GD12T4D Power Module

Engineered for demanding high-power applications, the Semikron-Danfoss SKiM304GD12T4D is a six-pack IGBT module designed to deliver robust thermal performance and long-term operational reliability. This module integrates Trench Gate IGBT4 technology to achieve a superior balance between conduction and switching losses. Key specifications include: 1200V Collector-Emitter Voltage | 300A Nominal Collector Current | VCE(sat) of 1.75V (typ). Its primary engineering benefits are enhanced thermal cycling capability and simplified, reliable driver assembly. For engineers designing high-reliability AC inverter drives, a critical question is how to ensure consistent, long-term performance under strenuous thermal loads. The SKiM304GD12T4D directly addresses this through its pressure contact technology, which eliminates solder fatigue points for critical thermal interfaces. For high-reliability drive applications requiring a robust and thermally stable inverter stage, this 1200V module provides a dependable foundation.

Application Scenarios & Value

Achieving System-Level Benefits in High-Frequency Power Conversion

The SKiM304GD12T4D is optimized for applications where reliability and thermal management are paramount. Its inherent design makes it a strong candidate for the core of high-power conversion systems.

- High-Reliability AC Inverter Drives: In industrial motor control, particularly in applications like conveyor systems, pumps, and fans, uptime is critical. A key engineering challenge is managing the thermal stress induced by continuous, high-current operation. The SKiM304GD12T4D's pressure contact system provides a direct, solder-free thermal path from the DCB substrate to the heatsink. This design mitigates the primary failure mechanism of solder fatigue, which can occur after thousands of thermal cycles, thereby extending the service life of the entire drive. The module's integrated temperature sensor also provides essential data for sophisticated thermal management and fault protection within the Variable Frequency Drive (VFD).

- Wind Turbine Inverters: The power conversion systems in wind turbines operate in harsh, often remote environments, making maintenance difficult and costly. The reliability of the power electronics is therefore a decisive factor. The SKiM304GD12T4D's robust mechanical design, featuring spring contacts for driver PCB mounting, ensures secure connections that resist vibration and mechanical shock—critical factors in nacelle-mounted equipment.

- Automotive Inverters: In the context of auxiliary automotive systems or specialized vehicle inverters, the module's low inductance case design helps minimize voltage overshoots during fast switching events, contributing to better electromagnetic compatibility (EMC) performance.

While this model is well-suited for applications up to the 300A range, for systems requiring lower power handling, the related BSM200GB120DN2 offers a different performance profile within the 1200V class.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The specifications of the SKiM304GD12T4D are tailored for robust performance in high-power switching applications. The following table highlights key parameters that directly influence its integration and operational efficiency.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | 1200 V | Tj = 25 °C |

| Continuous DC Collector Current | IC,nom / IC | 300 A / 450 A | Tcase = 25 °C / 80 °C |

| Collector-Emitter Saturation Voltage | VCE(sat) | 1.75 V (typ.) / 2.15 V (max.) | IC = 300 A, Tj = 25 °C / 125 °C |

| Gate-Emitter Threshold Voltage | VGE(th) | 5.8 V | IC = 12 mA |

| Total Switching Energy | Ets | 37 mJ (typ.) | IC = 300 A, VCE = 600 V, Tj = 125 °C |

| Short Circuit Withstand Time | tpsc | 10 µs | VCC = 800 V, Tj = 125 °C |

| Max. Junction Temperature | Tj,max | 150 °C | Operating |

Download the SKiM304GD12T4D datasheet for detailed specifications and performance curves.

Technical Deep Dive

A Closer Look at Solder-Free Contact Technologies for Long-Term Reliability

A standout feature of the SKiM304GD12T4D is its dual implementation of solder-free contact technologies: pressure contacts for the thermal interface and spring contacts for the gate drive connections. This design choice directly confronts common failure points in conventional IGBT modules. Pressure contact technology replaces the traditional soldered thermal interface between the module's baseplate and the heatsink. Think of it like swapping a glued connection for a high-tension bolt; the connection is not only strong but also resilient to the expansion and contraction that occurs during thermal cycling. This eliminates the risk of solder fatigue and void formation over the module's lifetime, ensuring a consistently low Thermal Resistance and efficient heat extraction.

Simultaneously, the spring-loaded contacts for the driver board simplify assembly and enhance reliability. Instead of requiring precise soldering that can be a source of manufacturing defects, the driver PCB is simply pressed onto the module, with the springs providing a consistent, vibration-resistant electrical connection. This significantly reduces assembly time and removes another potential point of solder-related failure, contributing to a lower total cost of ownership and higher field reliability, a key consideration for industrial systems with long operational lifecycles.

Frequently Asked Questions (FAQ)

What is the primary benefit of the pressure contact technology used in the SKiM304GD12T4D?

The primary benefit is enhanced long-term reliability. By creating a solder-free interface between the module's DCB and the heatsink, it eliminates the risk of solder fatigue failure caused by repeated temperature fluctuations, ensuring consistent thermal performance over the product's entire operational life.

How do the spring contacts for the driver PCB simplify the design process?

The spring contacts allow for a solder-free connection to the gate driver board. This simplifies the manufacturing process by removing a soldering step, which reduces assembly time and eliminates a potential source of production defects. It ensures a reliable, repeatable connection with consistent pressure.

What does the positive temperature coefficient of VCE(sat) mean for system design?

A positive temperature coefficient for VCE(sat) is a crucial feature for paralleling IGBT modules. As a chip heats up, its on-state voltage drop increases, naturally forcing current to share more evenly with other, cooler chips. This inherent self-balancing behavior simplifies the design of high-current inverter legs that require multiple modules to operate in parallel, preventing thermal runaway in any single device.

Strategic Outlook

For engineering teams developing next-generation power conversion platforms, the SKiM304GD12T4D represents a strategic choice focused on lifecycle value and reliability. The deliberate move towards solder-free contact technologies by manufacturers like Semikron-Danfoss reflects a broader industry trend towards more robust and easily serviceable power electronics. By designing-in components that mitigate known failure modes like solder fatigue, engineers can deliver systems with greater uptime and a lower total cost of ownership, aligning with the operational demands of industrial automation, renewable energy, and heavy-duty transportation sectors.