Content last revised on January 15, 2026

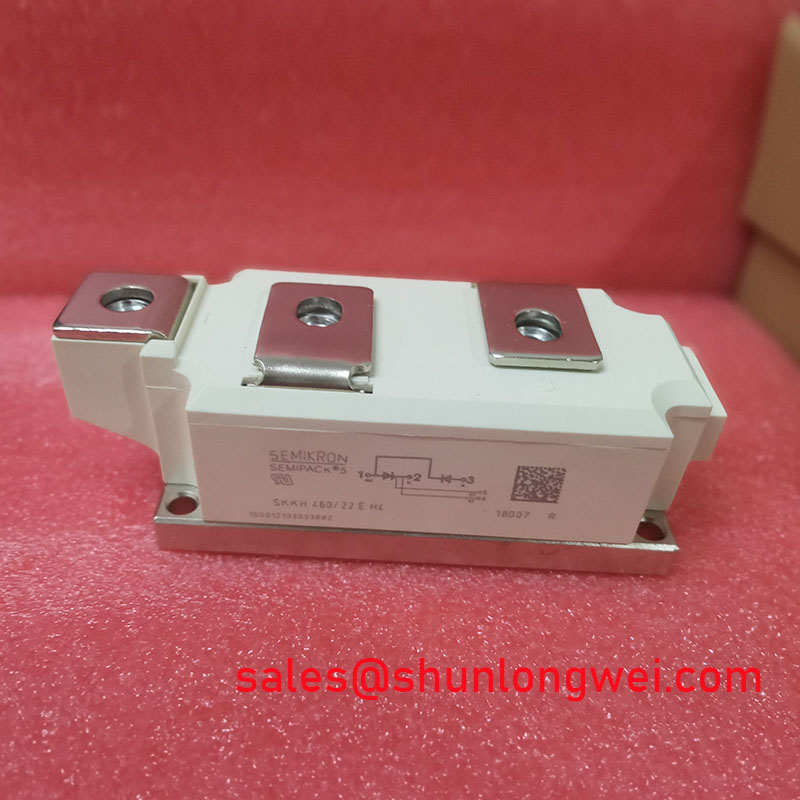

Semikron SKKH460/22EH4 | High-Power Thyristor/Diode Module for Controlled Rectification

The Semikron SKKH460/22EH4 is an engineered workhorse designed for high-power control and conversion applications. As a thyristor/diode module housed in the industry-proven SEMIPACK® 3 package, it delivers the robustness and reliability required for line-frequency systems where precise control and high current handling are non-negotiable. This isn't just a component; it's a foundational building block for resilient industrial power infrastructure.

Core Strengths of the SKKH460/22EH4

- High Power Density: With a forward current rating of 460A and a repetitive peak reverse voltage of 2200V, this module is engineered to manage substantial power loads, making it ideal for multi-megawatt systems.

- Proven Reliability: The SEMIPACK® 3 housing utilizes a pressure contact technology and an isolated baseplate, ensuring excellent thermal cycling capability and long operational life even under harsh industrial conditions.

- Optimized for Line Frequency: The characteristics of the thyristors and diodes are tailored for 50/60 Hz applications, providing efficient and stable phase-angle control for rectifiers and AC controllers.

- Simplified Thermal Design: The module's electrically isolated copper baseplate simplifies heatsink mounting and improves overall system thermal performance, a critical factor in high-power designs.

Application Scenarios & Engineering Value

The SKKH460/22EH4 excels where brute force reliability is paramount. Its specific topology (dual thyristor "half-bridge" or phase-leg) is purpose-built for several key industrial applications:

- Controlled Bridge Rectifiers: In the front-end of large Variable Frequency Drives (VFDs) or high-power DC supplies, these modules allow for fully controllable three-phase rectifiers. This enables regulated DC-bus voltage and can facilitate regenerative braking by operating in inverter mode.

- AC Voltage Controllers & Soft Starters: For large induction motors, the SKKH460/22EH4 provides a robust solution for building soft starters. By precisely controlling the firing angle of the thyristors, it can smoothly ramp up the voltage, drastically reducing mechanical shock and electrical inrush current.

- High-Current Battery Chargers: In industrial charging systems for logistics, mining, or backup power, this module can form the core of a powerful and controllable AC-DC converter, ensuring efficient and safe battery charging cycles.

Key Parameter Overview

For the design engineer, having critical data at your fingertips is essential. The table below summarizes the headline specifications for the Semikron SKKH460/22EH4. For comprehensive characteristic curves and design limits, please download the official datasheet.

| Parameter | Value |

|---|---|

| Repetitive Peak Reverse Voltage (VRRM) | 2200 V |

| Average On-state Current (ITAV) @ Tcase=80°C | 460 A (per thyristor) |

| RMS On-state Current (ITRMS) | 720 A (per thyristor) |

| Topology | Thyristor / Diode Module (Phase-Leg) |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.065 K/W (per thyristor) |

| Isolation Voltage (Visol) | 3600 V (AC, 1 minute) |

| Package | SEMIPACK® 3 |

Strategic Advantage in Industrial Power

In an era dominated by high-frequency switching with IGBTs and SiC, the strategic importance of thyristor technology in heavy industry remains undiminished. The SKKH460/22EH4 represents the principle of using the right tool for the job. For applications directly tied to the grid frequency, its lower switching losses and inherent ruggedness offer a more cost-effective and reliable solution. These devices are the backbone of power conversion in sectors like metals, paper, and chemical processing, where uptime is measured in dollars per minute. Investing in robust, proven thyristor and IGBT modules from a leading manufacturer like Semikron is a strategic decision for long-term system reliability.

Frequently Asked Questions (FAQ)

What are the critical gate drive requirements for the thyristors in this module?

A common oversight is an under-powered gate drive. To ensure a fast and complete turn-on (latching) of the thyristor, especially with highly inductive loads, the gate drive circuit must supply a strong current pulse with a fast rise time. A weak gate signal can lead to localized heating at the gate region, increasing conduction losses and potentially damaging the device over time. Always refer to the VGT and IGT specifications in the datasheet.

How does the module's thermal resistance impact overall system design?

The specified Thermal Resistance (Rth(j-c)) of 0.065 K/W is a critical value. It quantifies how efficiently heat can be transferred from the silicon die to the module case. A low value, like this one, is desirable. However, the overall system reliability depends on the entire thermal chain: from the module's baseplate, through the thermal interface material (TIM), to the heatsink. A poorly selected or improperly mounted heatsink will negate the benefits of the module's excellent thermal design, leading to higher operating junction temperatures and a reduced operational lifespan. Proper thermal management is key to leveraging the full capability of these high-power power modules.