Content last revised on December 1, 2025

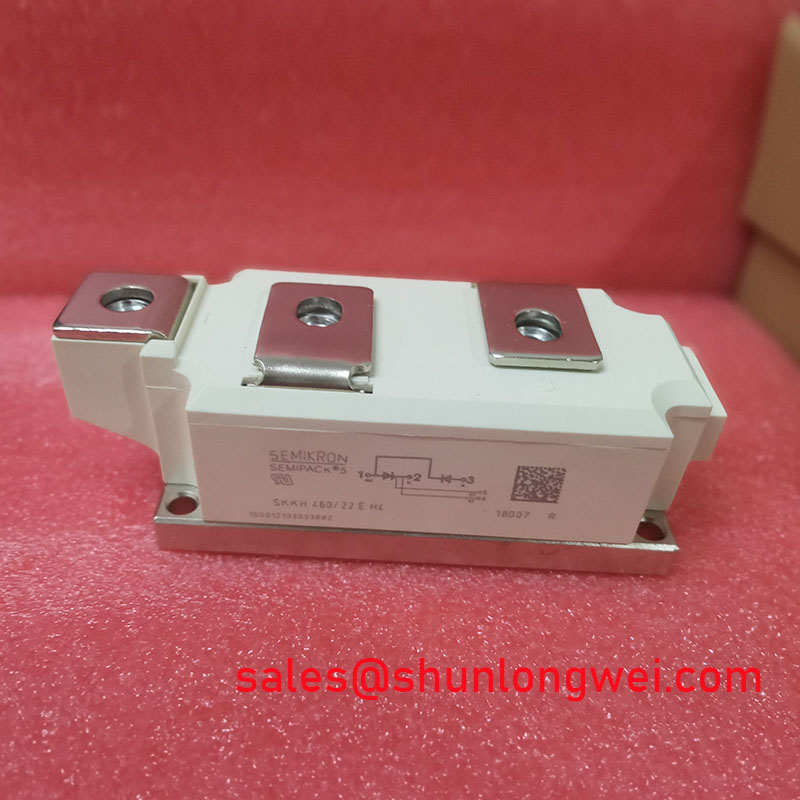

SKKH56/08D: A Robust 800V Dual Thyristor Module for Industrial Power Control

The SKKH56/08D is a high-reliability dual thyristor module from SEMIKRON, engineered for robust thermal performance and long-term stability in demanding power control systems. It delivers a formidable combination of 800V blocking voltage and a 56A average forward current, featuring exceptional surge handling capabilities and an electrically isolated baseplate. Key benefits include simplified thermal design and enhanced operational ruggedness. This module is an excellent engineering choice for implementing efficient and durable phase control in applications like industrial AC motor soft starters. For systems requiring robust, line-commutated power regulation, this 800V module provides a well-balanced solution.

Key Parameter Overview

Decoding Key Electrical and Thermal Specifications

The SKKH56/08D's specifications are tailored for high-reliability industrial applications where both thermal stability and electrical ruggedness are paramount. The parameters below highlight its capacity for controlled power handling under strenuous operating conditions. A thorough understanding of these values is critical for effective heatsink selection and ensuring system longevity.

| Electrical Characteristics (Tcase = 105 °C unless otherwise specified) | |

|---|---|

| Repetitive Peak Off-State and Reverse Voltage (VDRM, VRRM) | 800V |

| Average On-State Current (ITAV) @ Tcase=85°C | 56A |

| RMS On-State Current (ITRMS) | 95A |

| Surge On-State Current (ITSM) @ 10 ms, Tvj=25°C | 900A |

| I²t Value for Fusing (I²t) @ 10 ms, Tvj=25°C | 4050 A²s |

| Thermal and Mechanical Characteristics | |

| Thermal Resistance, Junction to Case (Rth(j-c)) per thyristor, DC | 0.5 °C/W |

| Operating Junction Temperature Range (Tvj) | -40 to 130 °C |

| Isolation Test Voltage (VISOL), 50/60 Hz, 1 min | 2500V |

| Module Type | SEMIPACK® 1 with isolated copper baseplate |

Download the SKKH56/08D datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Advantages in Industrial Power Control

The SKKH56/08D is engineered to excel in medium-power AC and DC load control applications where precise and reliable power regulation is non-negotiable. For designers of AC Motor Soft Starter systems, this module offers a distinct advantage. Its high surge current rating (ITSM of 900A) provides the necessary headroom to withstand the initial inrush currents of induction motors without risking component failure. This robustness ensures a smooth and controlled voltage ramp-up, reducing mechanical stress on the motor and connected equipment.

In applications like industrial temperature controllers or lighting dimmers, the module's Phase Control capability allows for precise energy delivery. The low thermal resistance (Rth(j-c)) is critical here; it ensures efficient heat transfer from the thyristor junctions to the heatsink. This is not just a number; it directly translates to smaller, more cost-effective cooling solutions or higher operational reliability at a given power level. The module’s architecture is also well-suited for building cost-effective Controlled Rectifier bridges for DC power supplies and battery chargers. For systems that require rectification of higher currents, the related SKKD162/16 diode module offers a higher current handling capability in a compatible package footprint.

Technical Deep Dive

An Inside Look at the Construction for Enhanced Reliability

A key engineering feature of the SKKH56/08D is its construction, which centers on an isolated copper baseplate using Aluminum Oxide (Al₂O₃) ceramic. What is the primary benefit of its pressure-contact design? Enhanced long-term reliability by eliminating solder fatigue. This design choice provides two significant system-level benefits. First, it delivers excellent electrical isolation of 2500V, allowing the module to be mounted directly to a common, grounded heatsink without needing fragile and thermally inefficient isolation pads. This simplifies mechanical assembly and improves the overall thermal design of the power stage.

Second, this structure enhances thermal cycling capability. The glass passivation on the thyristor junction is like a hermetic seal on a sensitive instrument, protecting it from environmental contaminants and electrical degradation over decades of service. This construction minimizes the mechanical stress induced by temperature fluctuations, a common failure point in modules that rely on soldered connections. This intrinsic ruggedness makes the SKKH56/08D a preferred component for equipment deployed in harsh industrial environments with frequent power cycles, such as in automated welding equipment or process control systems. You can learn more about the manufacturer's technology at Semikron Danfoss.

Frequently Asked Questions (FAQ)

Engineering Questions on the SKKH56/08D

How does the isolated baseplate on the SKKH56/08D simplify the design of a power control cabinet?

The integrated 2500V isolation allows multiple modules to be mounted on a single, non-isolated heatsink without the risk of short circuits. This eliminates the need for separate, often fragile, thermal interface materials for isolation, reducing assembly complexity, improving thermal transfer, and saving valuable cabinet space.

What is the role of the VDRM rating of 800V in AC line applications?

A VDRM of 800V provides a robust safety margin for applications running on 230V or 400V AC lines. It ensures the thyristors can safely block the peak voltages of the AC waveform, including transient spikes and line swells, which is crucial for building reliable AC Motor Soft Starter and controlled rectifier systems.

For designs requiring proven thermal stability and robust power handling in the sub-100A range, the SKKH56/08D presents a compelling engineering choice. To evaluate this dual thyristor module for your next power control project, please contact our technical sales team for further information.