Content last revised on January 26, 2026

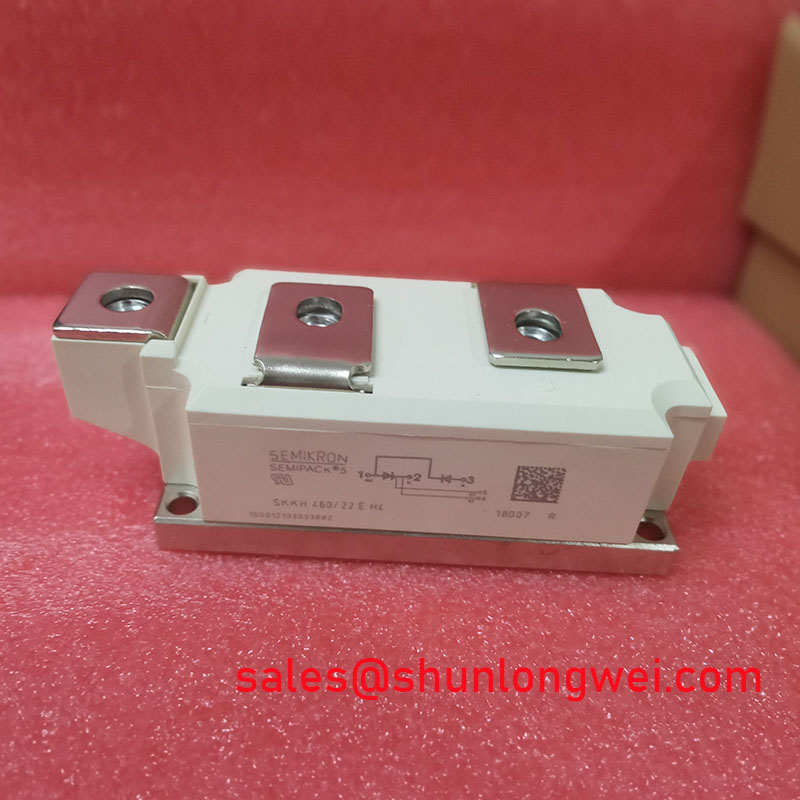

SK 45 WT 16: Thyristor Module for Reliable High-Power AC Control

The SK 45 WT 16 is an antiparallel thyristor module engineered for robust performance in AC power control applications. It delivers exceptional thermal performance and simplified assembly, leveraging a Direct Copper Bonded (DBC) substrate and a compact housing for enhanced reliability. With core specifications of 1600V | 47A | Rth(j-s) 0.6 K/W, this module provides superior thermal transfer and simplified mechanical mounting. For engineers designing compact soft starters or industrial temperature controllers, the SK 45 WT 16 offers a thermally efficient solution that streamlines manufacturing. What is the primary benefit of its DBC construction? It ensures low thermal resistance for cooler operation and extended service life.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The specifications of the SK 45 WT 16 are tailored for demanding AC power control systems where thermal management and electrical stability are critical. The highlighted parameters below are decisive for achieving reliable performance and optimizing system design.

| Parameter | Symbol | Value | Engineering Significance |

| Max. Repetitive Peak Off-State Voltage | VDRM, VRRM | 1600 V | Provides substantial voltage headroom for direct use in 400V/480V AC line applications, ensuring reliability against line transients. |

| RMS On-State Current (Case Temp. @ 85°C) | IRMS | 47 A | Defines the continuous current handling capability under specific thermal conditions, critical for sizing in applications like industrial heating control. |

| Thermal Resistance, Junction to Sink (per module) | Rth(j-s) | 0.6 K/W | A key indicator of thermal efficiency. This low value, enabled by the DBC substrate, facilitates effective heat removal, allowing for smaller heatsinks or higher power density. |

| Peak Surge Current (t=10 ms, Tvj=125°C) | ITSM | 380 A | Indicates the module's robustness against non-repetitive fault currents, essential for surviving motor starting inrush in AC motor soft starter designs. |

| Critical rate of rise of off-state voltage | (dv/dt)cr | 1000 V/µs | Represents high immunity to false triggering caused by rapid voltage changes on the AC line, ensuring stable operation in noisy industrial environments. |

Download the SK 45 WT 16 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in AC Power Control

The SK 45 WT 16 is engineered for applications where precise control of AC power, high reliability, and a compact design are paramount. Its feature set provides tangible benefits for system designers, particularly in industrial automation and power regulation. For systems requiring lower voltage blocking, the related SKKD162/16 offers a similar current rating with a different package and voltage class.

A primary application is in the design of AC motor soft starters. Here, engineers face the challenge of managing high inrush currents during motor startup without causing mechanical stress or electrical disturbances. The SK 45 WT 16's high surge current rating (ITSM of 380A) directly addresses this, allowing the module to safely handle the initial current surge. The use of phase-angle control, enabled by this thyristor module, allows for a smooth ramp-up of motor voltage, reducing mechanical shock and extending the lifetime of both the motor and connected equipment. The module's compliance with standards like IEC 60947-4-2 for motor controllers is a critical design consideration.

Other key applications include:

- Industrial Heating and Temperature Control: Its precise switching capability makes it ideal for regulating power to resistive heating elements, ensuring stable process temperatures in manufacturing.

- Lighting Control Systems: Used in high-power theatrical lighting dimmers and architectural lighting, where smooth and reliable power adjustment is necessary.

- AC Voltage Controllers: Serves as the core switching element in static AC power supplies and voltage regulation systems.

Frequently Asked Questions (FAQ)

How does the Direct Copper Bonded (DBC) substrate in the SK 45 WT 16 improve reliability compared to other designs?

The DBC substrate provides superior thermal performance and mechanical stability. It consists of a ceramic insulator (Aluminium Oxide) to which pure copper is bonded directly. This structure has a coefficient of thermal expansion (CTE) that is much closer to that of the silicon chip than traditional copper baseplates. This matching reduces mechanical stress on the chip during temperature cycles, minimizing the primary failure mechanism of solder fatigue and significantly extending the module's operational life and power cycling capability.

What is the main advantage of the single-screw mounting feature of the SEMITOP 2 housing?

The primary advantage is simplified and cost-effective assembly. A single screw ensures a defined and even pressure distribution across the module's base, which is critical for achieving the specified low thermal resistance to the heatsink. This eliminates the complexity of torqueing multiple screws in a specific sequence, reducing assembly time, minimizing the risk of improper mounting, and improving manufacturing throughput.

Can the SK 45 WT 16 be used on a 60Hz system if the datasheet specifies tests at 50Hz?

Yes, absolutely. The SK 45 WT 16 is designed for line-frequency applications and performs equally well on both 50Hz and 60Hz systems. The parameters like (di/dt)cr specified at 50/60Hz confirm its suitability for both standard mains frequencies without any degradation in performance or reliability.

Technical Deep Dive

A Closer Look at the Thermal Pathway: From Chip to Heatsink

The long-term reliability of any power module is fundamentally tied to its ability to manage heat. The SK 45 WT 16 excels in this regard due to its intelligent thermal design, centered on the DBC substrate. Think of the thermal pathway as a highway for heat energy; any bottleneck restricts flow and causes a "traffic jam," which in this case is a rise in junction temperature (Tvj). The DBC construction acts like a multi-lane, unobstructed superhighway.

The low thermal resistance (Rth(j-s)) of 0.6 K/W means that for every watt of power dissipated as heat, the temperature difference between the silicon thyristor junction and the module's seating plane is only 0.6°C. This efficiency is critical. It allows designers to either push more current through the device while staying within safe temperature limits or to use a smaller, less expensive heatsink for the same current, directly impacting the final system's cost and power density. This thermal efficiency is a direct result of eliminating thermally inefficient layers, a core benefit of the technology provided by manufacturers like Semikron Danfoss.

Strategic Advantage

For engineering teams and procurement managers, adopting the SK 45 WT 16 is a strategic decision that favors total cost of ownership (TCO) over initial component price. The module's design, which simplifies assembly and enhances thermal management, reduces hidden costs associated with manufacturing labor, oversized cooling solutions, and potential field failures. By building reliability into the core of the component through its glass-passivated chips and robust DBC structure, the SK 45 WT 16 supports the development of more competitive end-products with longer service lives and lower warranty costs.