Content last revised on November 17, 2025

Fuji Electric 2MBI400TC-060-01 | Engineered for High-Current, Low-Frequency Power Conversion

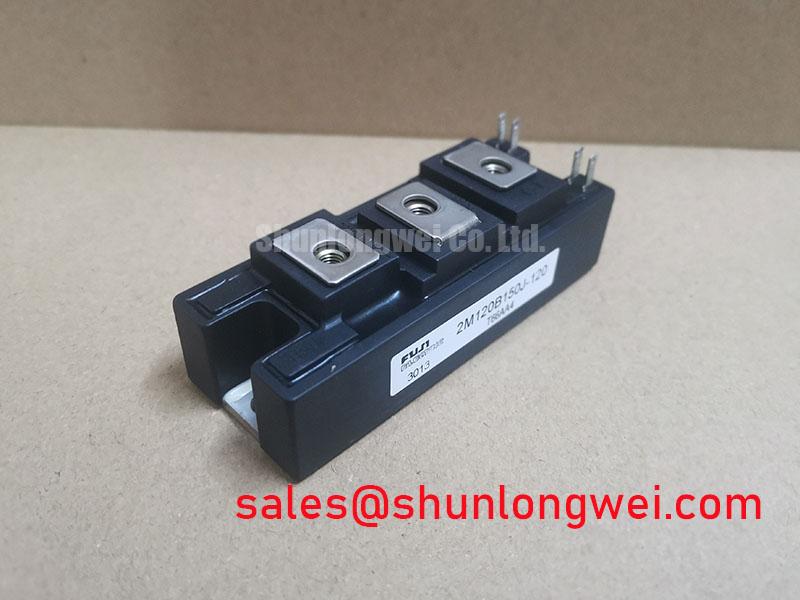

The Fuji Electric 2MBI400TC-060-01 is a robust dual IGBT module designed for engineers who require uncompromising reliability and high current handling in demanding industrial power systems. This half-bridge module, rated for 600V and 400A, is built upon a foundation of proven Non-Punch-Through (NPT) technology, making it a workhorse for applications where low conduction losses and operational toughness are paramount.

- High Current Capability: With a continuous collector current rating of 400A, it is ideally suited for high-power inverter and converter stages.

- Robust NPT IGBT Technology: Delivers a wide Safe Operating Area (SOA) and excellent short-circuit ruggedness, ensuring system survivability under fault conditions.

- Low Conduction Losses: A low saturation voltage (VCE(sat)) minimizes heat generation during on-state, which directly improves system efficiency and simplifies thermal design.

- Industry-Standard Package: Housed in a standard M242 package, facilitating straightforward mechanical integration and drop-in replacement for existing designs.

Key Parameter Overview

The following specifications represent the core performance characteristics of the 2MBI400TC-060-01. For a comprehensive analysis, designers should consult the official product datasheet. Download the 2MBI400N-060-01 datasheet (Note: link is for a closely related variant).

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 600 V |

| Continuous Collector Current (I_C) at T_c=25°C | 400 A |

| Collector-Emitter Saturation Voltage (V_CE(sat)) typ. at I_C=400A | 2.1 V |

| Total Power Dissipation (P_C) per IGBT | 1560 W |

| Maximum Junction Temperature (T_j(max)) | 150 °C |

| Package Type | M242 |

Application Scenarios & Engineering Value

The specific characteristics of the 2MBI400TC-060-01 make it an exceptional choice for the following high-power applications:

- Variable Frequency Drives (VFDs): In large motor drives, its high current rating effortlessly manages the power required for induction and synchronous motors. Its robustness is crucial for handling high inrush currents during motor startup and regenerative braking events.

- Industrial Welding Power Supplies: The module's excellent SCSOA (Short Circuit Safe Operating Area) and ability to handle pulsed, high-current loads make it a reliable core component for industrial welding systems, ensuring longevity despite harsh electrical cycles.

- High-Power Uninterruptible Power Supplies (UPS): For data centers and critical facilities, this module serves as the backbone of the inverter stage. Its low VCE(sat) contributes to higher overall UPS efficiency, reducing operating costs and thermal load.

Technical Deep Dive: The Advantage of NPT Technology

While modern power electronics often focus on high-frequency performance, the Fuji Electric 2MBI400TC-060-01 leverages the strategic advantages of Non-Punch-Through (NPT) IGBT technology. Unlike Trench-Gate Field-Stop designs optimized for speed, NPT silicon prioritizes ruggedness. A key engineering benefit is the positive temperature coefficient of its VCE(sat). As an individual IGBT chip heats up, its on-state resistance increases slightly. When modules are paralleled to achieve higher current ratings, this characteristic forces a natural load balancing. A hotter device will conduct slightly less current, preventing thermal runaway and simplifying the busbar and gate drive design for multi-module arrays. This intrinsic stability is a significant factor in building scalable and fault-tolerant power systems.

Frequently Asked Questions (FAQ)

Can the 2MBI400TC-060-01 be used in high-frequency applications like induction heating?

While possible, this module is optimized for low- to medium-frequency applications (typically below 20 kHz) where conduction losses dominate. For higher frequencies, a module with lower switching losses, such as one from Fuji Electric's V-Series or X-Series, would likely offer better overall performance by reducing switching-related heat generation.

What is the most critical design consideration when implementing this module?

Effective thermal management. Given its 400A rating and associated conduction losses, ensuring a low-resistance thermal path is vital. This involves selecting an appropriately sized heatsink, using high-quality thermal interface material (TIM), and verifying proper mounting torque to minimize the junction-to-case thermal resistance (Rth). A robust thermal design is key to unlocking the module's full power capability and ensuring long-term reliability.

For detailed selection advice or to discuss your specific application needs, please contact our technical team for expert consultation.