Content last revised on November 15, 2025

6MBP100RS120 Power Integrated Module: Technical Review for Motor Drive Applications

Introduction to the 6MBP100RS120 PIM

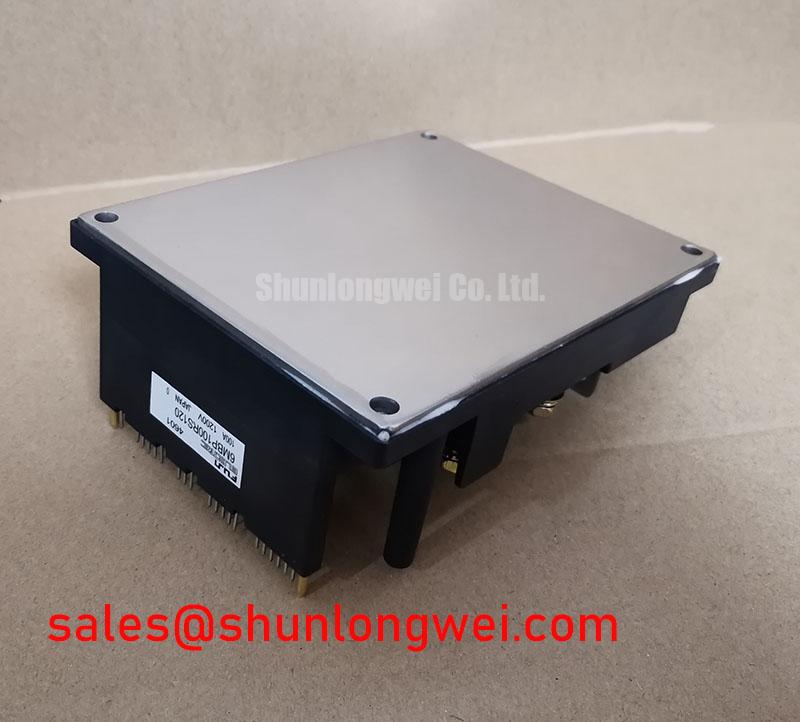

The Fuji Electric 6MBP100RS120 is a highly integrated 1200V Power Integrated Module (PIM) engineered for thermally efficient and reliable motor drive applications. This component streamlines power stage design by combining a three-phase diode converter, a three-phase IGBT inverter, and a brake chopper circuit into a single, compact package. Key Specifications: 1200V | 100A (Inverter IGBT) | VCE(sat) 2.7V (Max). Its primary engineering benefits include a significantly simplified system architecture and direct, real-time thermal monitoring capabilities. The module is specifically designed to address the challenge of creating compact, high-power drives by providing individually characterized thermal data for its integrated converter, inverter, and brake stages. For compact AC motor drives up to 15 kW requiring a streamlined design with robust, built-in thermal protection, this PIM presents a compelling engineering solution.

Key Parameter Overview

Decoding the Specifications for Thermal Design and Efficiency

The performance of the 6MBP100RS120 is defined by its electrical and thermal characteristics. The following parameters are critical for system-level design, particularly for optimizing efficiency and ensuring long-term operational reliability. Highlighting these key metrics allows engineers to accurately model system performance under various load conditions.

| Parameter | Symbol | Condition | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | - | 1200V |

| Collector Current (Inverter) | IC | Tc=80°C | 100A |

| Collector Current (Brake) | IC | Tc=80°C | 50A |

| Collector-Emitter Saturation Voltage (Inverter) | VCE(sat) | IC=100A, Tj=125°C | 2.7V (Max) |

| Forward Voltage (FWD) | VF | IF=100A, Tj=125°C | 2.6V (Max) |

| Thermal Resistance (Inverter IGBT) | Rth(j-c) | Junction to Case | 0.19 °C/W (Max) |

| Thermal Resistance (Converter Diode) | Rth(j-c) | Junction to Case | 0.31 °C/W (Max) |

| Short Circuit Withstand Time | tsc | VCC=600V, VGE=15V, Tj=125°C | ≥10 µs |

For a complete list of specifications, electrical characteristics, and performance graphs, please refer to the official datasheet.

Application Scenarios & Value

System-Level Benefits in AC Drives and Servo Systems

The integrated nature of the 6MBP100RS120 provides significant value in applications where space, assembly cost, and thermal performance are critical design constraints. Its all-in-one architecture is particularly suited for:

- Variable Frequency Drives (VFDs): In compact VFDs for AC induction or permanent magnet motors, this PIM reduces the power stage component count from three separate modules (rectifier, inverter, brake) to one. This minimizes layout complexity, reduces potential EMI loops, and simplifies the supply chain.

- Servo Drives: For industrial robotics and CNC machinery, the module's fast switching characteristics and integrated brake chopper provide the precise motor control and dynamic braking required. The built-in NTC thermistor offers a direct feedback path for ensuring the drive operates within its Safe Operating Area (SOA), enhancing machine reliability.

- General-Purpose Inverters: In applications like commercial HVAC systems or pumps, the module's efficiency, driven by a low VCE(sat), contributes to lower energy consumption and reduced operational costs over the system's lifetime.

The engineering value lies in its ability to accelerate the design cycle. By providing a pre-qualified, integrated solution with well-defined thermal properties, engineers can focus on control logic and system optimization rather than on the intricate layout and thermal validation of discrete power stages. What is the key benefit of the integrated NTC thermistor? It enables direct, real-time junction temperature monitoring for robust system protection.

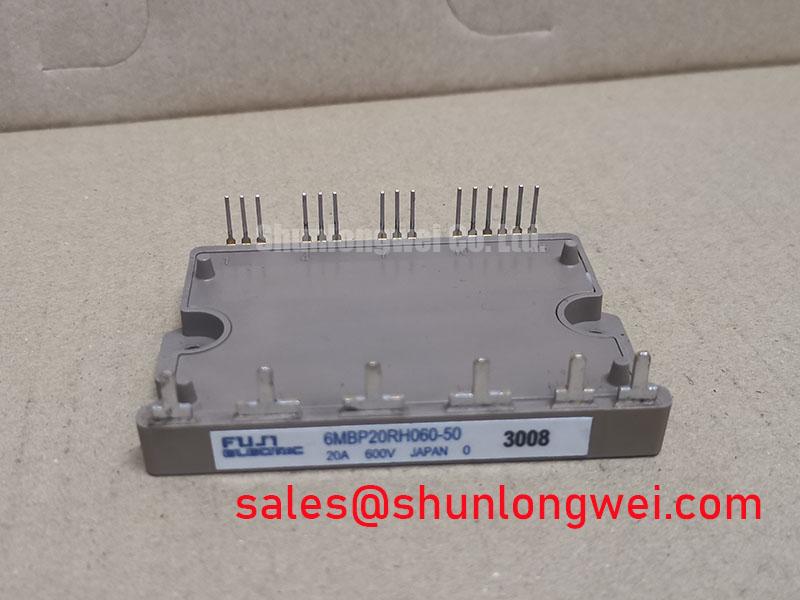

For systems with different current requirements or configurations, related components may be considered. For example, the 6MBP75RS120 offers a similar integrated topology at a 75A rating, while the PM100CSD120 provides an intelligent power module (IPM) solution with integrated gate drivers for further design simplification.

Engineering Questions on the 6MBP100RS120

What is the primary advantage of using a PIM like the 6MBP100RS120 over discrete components?

The main advantage is system integration. It combines the input rectifier, output inverter, and braking chopper into a single module, which reduces PCB size, simplifies assembly, shortens design time, and can improve reliability by minimizing interconnects.

How does the integrated NTC thermistor improve system reliability?

The NTC thermistor provides a direct measurement of the module's internal temperature. This allows the system's microcontroller to implement precise over-temperature protection (OTP). It can trigger alarms, reduce output power (derating), or initiate a safe shutdown before the IGBTs reach a critical temperature, preventing catastrophic failure and extending the drive's operational life.

What does the Rth(j-c) value of 0.19 °C/W for the inverter IGBT signify for thermal design?

This value represents the thermal resistance from the IGBT junction to the module's case. A lower value is better, as it indicates more efficient heat transfer away from the semiconductor. This specific value is crucial for calculating the expected junction temperature under a given load and for selecting an appropriate heatsink to maintain the device within its safe operating temperature range.

Is the 6MBP100RS120 suitable for high-frequency switching applications?

The datasheet provides switching times (tr, tf) that allow engineers to calculate switching losses. While suitable for typical motor drive frequencies (e.g., 2-15 kHz), its performance at higher frequencies (>20 kHz) must be carefully evaluated. At higher frequencies, switching losses become dominant, and the thermal management system must be robust enough to dissipate the increased heat generated.

Strategic Implications for Power System Design

Opting for an integrated module like the 6MBP100RS120 represents a strategic shift from component-level design to system-level optimization. It allows engineering teams to allocate resources more effectively, focusing on value-added areas such as advanced control algorithms, user interface development, and network connectivity. This approach not only accelerates time-to-market but also yields a more compact, cost-effective, and often more reliable end product. For organizations aiming to streamline their manufacturing processes and enhance the power density of their motor control solutions, leveraging the integration offered by this Fuji Electric PIM is a key enabler for competitive advantage.