Content last revised on November 17, 2025

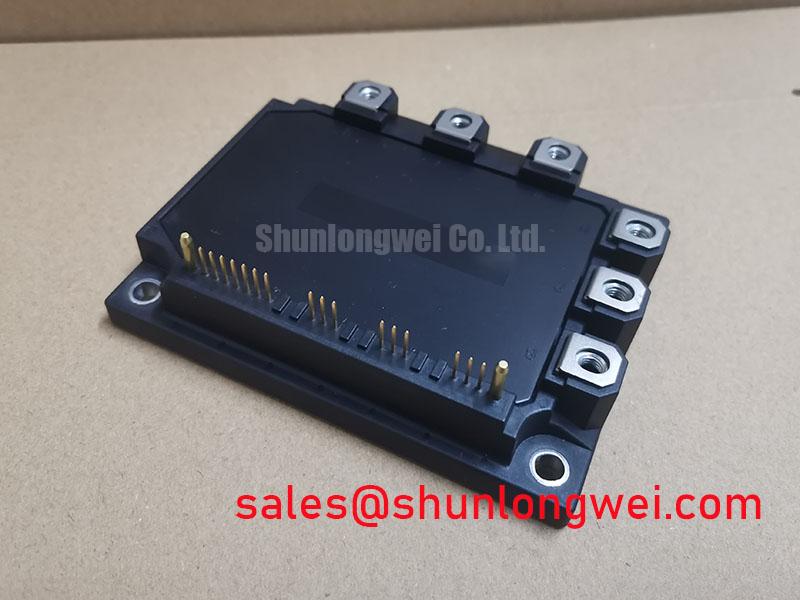

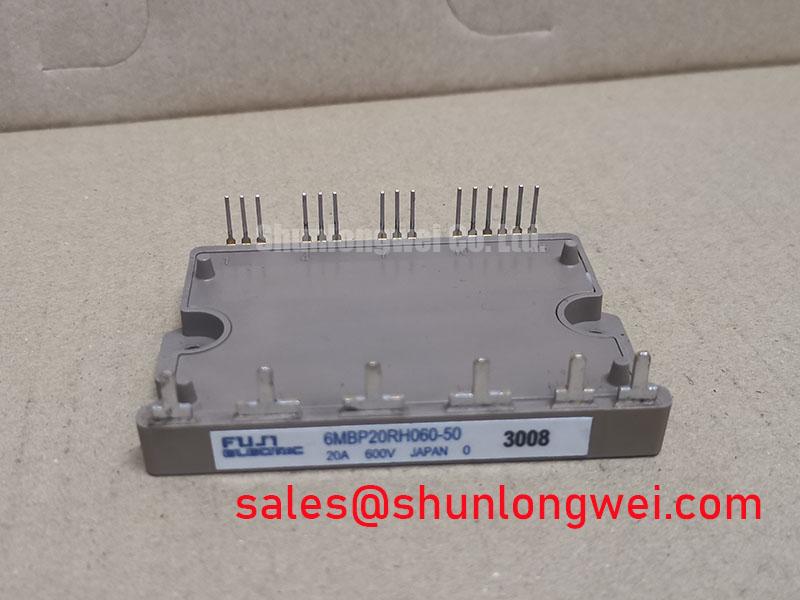

6MBP150RTA060 | 600V 150A PIM IGBT for High-Efficiency Motor Control

Introduction: Core Specifications & Engineering Value

Optimizing Inverter Designs for Performance and Power Density

The Fuji Electric 6MBP150RTA060 is a 600V, 150A Power Integrated Module (PIM) engineered to deliver an exceptional balance of low conduction loss and robust performance. It integrates a three-phase IGBT inverter bridge, a brake chopper, and a three-phase diode rectifier bridge into a single, compact package. Key specifications include: 600V | 150A (Inverter) | VCE(sat) of 1.9V (typ). This module offers engineers tangible benefits such as enhanced energy efficiency and simplified thermal management. For designers of compact Variable Frequency Drives (VFDs), the module's low saturation voltage directly translates into reduced heat generation, enabling smaller heatsinks and higher power density. This integrated approach provides a streamlined solution for systems where space and efficiency are critical design constraints.

Application Scenarios & Value

System-Level Benefits in Industrial Automation and Power Conversion

The 6MBP150RTA060 is best suited for applications where efficiency, reliability, and a compact footprint are paramount. Its all-in-one configuration significantly simplifies the power stage design for a range of systems.

- Variable Frequency Drives (VFDs): In a typical 30-45 kW motor drive application, the primary engineering challenge is managing thermal load within a sealed enclosure. The 6MBP150RTA060's typical collector-emitter saturation voltage (VCE(sat)) of 1.9V at its rated current is a decisive factor. This low VCE(sat) minimizes conduction losses, which are a major source of heat during motor operation. This reduction in waste heat allows for a smaller, more cost-effective heatsink and improves the overall reliability of the drive by lowering the operating temperature of critical components.

- Uninterruptible Power Supplies (UPS): In online double-conversion UPS systems, efficiency is key to reducing operating costs. The module's integrated design, combining both rectifier and inverter stages, streamlines the power flow and reduces component count, contributing to a more robust and efficient power conversion process.

- Servo Drives: The module's performance supports the dynamic load requirements of robotic and CNC servo applications, providing the necessary control and power handling for precision motion control systems.

For systems requiring a different current rating but a similar integrated topology, engineers may also evaluate the 6MBP100RTA060 for 100A requirements or the 6MBP200RA060 for applications needing up to 200A.

Key Parameter Overview

Highlighted Specifications for Performance Evaluation

The following table highlights the critical electrical and thermal parameters of the 6MBP150RTA060, derived from the official datasheet. These values are essential for performing accurate loss calculations and thermal simulations during the design phase.

| Parameter | Symbol | Condition | Value |

|---|---|---|---|

| Collector-Emitter Voltage (Inverter) | VCES | - | 600V |

| Continuous Collector Current (Inverter) | IC | Tc = 80°C | 150A |

| Collector-Emitter Saturation Voltage (Inverter) | VCE(sat) | IC = 150A, VGE = 15V | 1.9V (typ) / 2.4V (max) |

| Forward Voltage (FWD) | VF | IF = 150A, VGE = 0V | 1.8V (typ) / 2.3V (max) |

| Repetitive Peak Reverse Voltage (Rectifier) | VRRM | - | 1600V |

| Average Forward Current (Rectifier) | IF(AV) | - | 150A |

| Thermal Resistance (Inverter IGBT, Junction-to-Case) | Rth(j-c) | - | 0.19°C/W |

| Operating Junction Temperature | Tj | - | +150°C (max) |

For a complete list of specifications, electrical characteristics, and performance graphs, please download the 6MBP150RTA060 datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Engineering Significance of Low VCE(sat) in IGBT Modules

A low Collector-Emitter Saturation Voltage, or VCE(sat), is one of the most critical parameters for an IGBT used in motor drives and inverters. Think of VCE(sat) as the "resistance" of a fully open water valve. A lower resistance means less pressure is lost as water flows through, translating to less wasted energy. Similarly, a lower VCE(sat) means the IGBT dissipates less power as heat when it's conducting current. For the 6MBP150RTA060, the typical VCE(sat) of 1.9V means that for every 100 amps of current, the device generates approximately 190 watts of heat due to conduction. A module with a VCE(sat) of 2.2V would generate 220 watts under the same conditions—a nearly 16% increase in conduction losses that must be managed by the cooling system.

This efficiency gain is a direct result of the underlying semiconductor technology, often involving advanced trench-gate structures. This technology optimizes the internal architecture of the IGBT chip to reduce on-state voltage drop. However, this often involves a trade-off with switching losses. To explain this trade-off, imagine a heavy, perfectly sealed vault door. It's very efficient when closed (low conduction loss), but it takes a lot of time and energy to open and close (high switching loss). A lighter door might not seal as perfectly but can be operated quickly (lower switching loss). The 6MBP150RTA060 is engineered by Fuji Electric to find an optimal balance for motor drive frequencies, prioritizing lower conduction losses as they are often the dominant loss factor in these applications.

Frequently Asked Questions (FAQ)

What are the primary engineering implications of the 1.9V typical VCE(sat)?

A VCE(sat) of 1.9V directly reduces conduction power loss (P_cond = VCE(sat) * IC), leading to higher inverter efficiency and a lower thermal load. This enables designers to specify smaller, lighter heatsinks, which in turn allows for more compact and cost-effective overall system designs, a key requirement in modern VFDs.

How does the integrated NTC thermistor benefit the system design?

The built-in NTC thermistor provides a direct, real-time measurement of the module's baseplate temperature. This eliminates the need for an external temperature sensor, reducing component count and simplifying assembly. The thermistor's output can be fed directly into the control logic to trigger over-temperature warnings or protective shutdowns, significantly enhancing the long-term reliability of the power system.

What is the purpose of the integrated brake chopper in this module?

The brake chopper (an IGBT and a freewheeling diode) is used to manage regenerative energy. When a motor decelerates, it acts as a generator, sending energy back to the DC bus. The brake chopper dissipates this excess energy through an external braking resistor, preventing the DC bus voltage from rising to dangerous levels and protecting the inverter.

Is this module suitable for high-frequency switching applications?

The 6MBP150RTA060 is optimized for typical motor drive frequencies, generally in the range of 2 kHz to 15 kHz, where its low conduction losses offer the most benefit. While it can operate at higher frequencies, designers must carefully analyze the increase in switching losses and ensure the thermal management system can handle the additional heat. For an in-depth guide on this topic, see our article on IGBT selection for high-frequency designs.

What are the recommended gate drive voltage settings for this IGBT?

For optimal performance, a gate-emitter voltage (VGE) of +15V is recommended to ensure the IGBT is fully saturated (turned on) to achieve the low VCE(sat). A negative gate voltage of -5V to -15V is typically recommended for turn-off to provide a strong margin against noise-induced turn-on, especially in electrically noisy industrial environments.

Strategic Considerations for System Design

Integrating the 6MBP150RTA060 into a power system offers a strategic path toward achieving higher power density and simplified manufacturing. The module's all-in-one PIM architecture reduces the number of high-power connections, minimizing stray inductance and potential failure points compared to a discrete solution. This high level of integration accelerates the design cycle and simplifies the supply chain by consolidating multiple power stage functions into a single component. For organizations focused on optimizing total cost of ownership (TCO), the reliability and efficiency gains offered by this module contribute to longer system life and lower energy consumption, aligning with long-term sustainability and performance goals.