Content last revised on November 15, 2025

7MBR15VKC120-50 | 1200V 15A 7-in-1 IGBT Module | Fuji PIM

Introduction to the 7MBR15VKC120-50

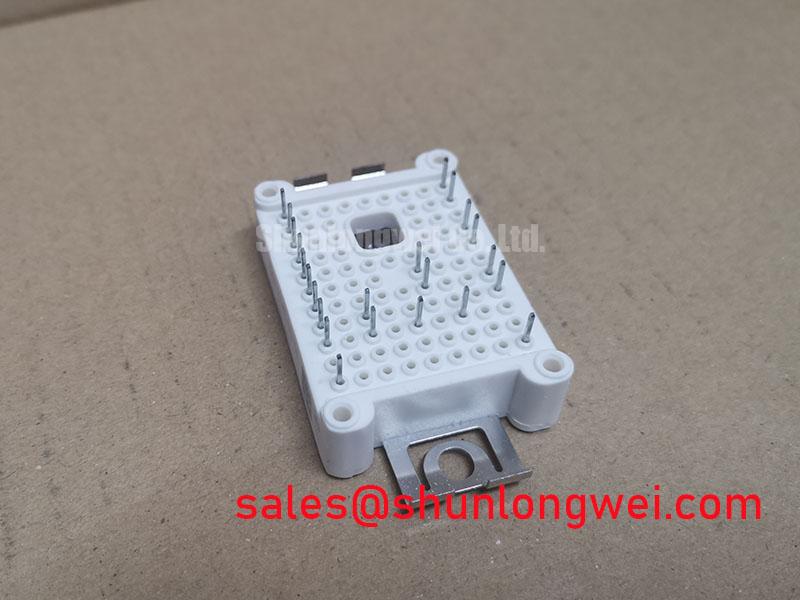

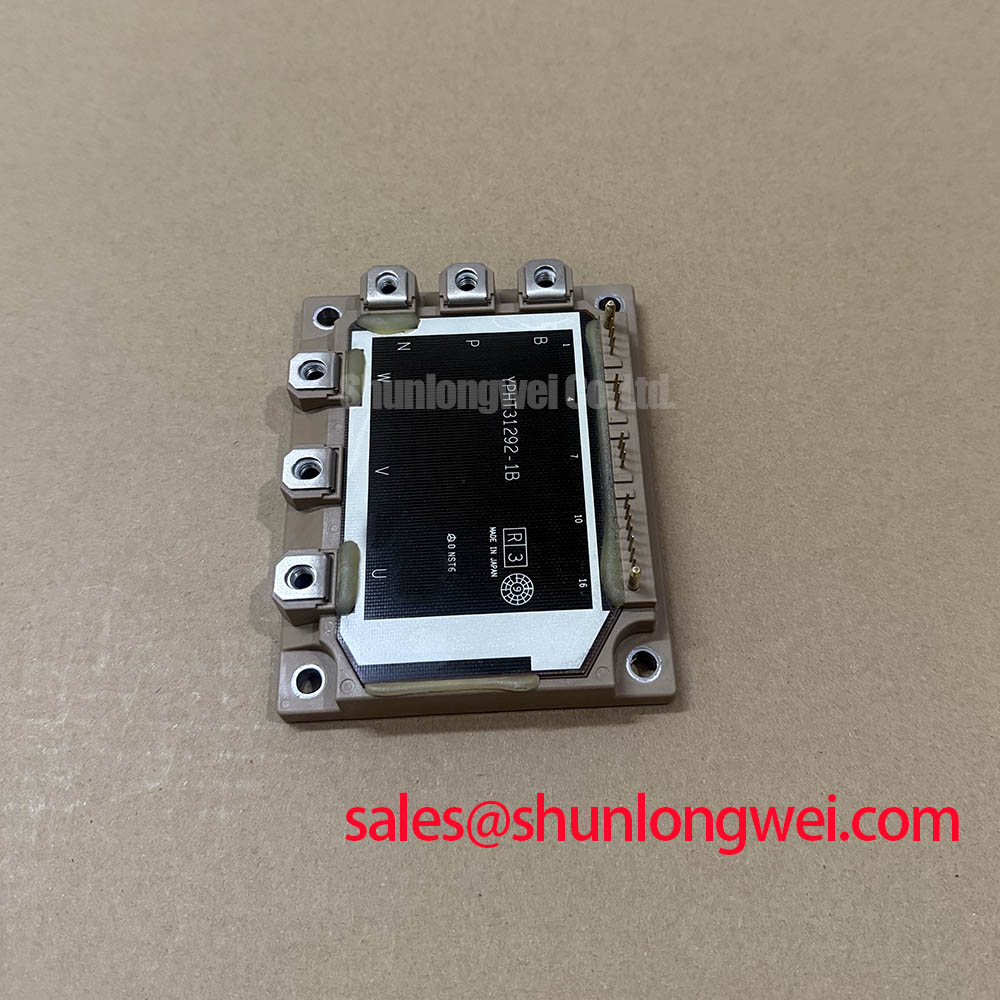

The Fuji 7MBR15VKC120-50 is a 1200V/15A Power Integrated Module (PIM) engineered to accelerate design cycles for compact motor drives by integrating a complete 7-in-1 power stage. With key specifications of 1200V | 15A | VCE(sat) 1.75V, this module offers substantial design benefits including a simplified PCB layout and reduced assembly time. It directly addresses the engineering challenge of minimizing system complexity by co-packaging the converter, inverter, and brake chopper, thereby reducing component count and streamlining thermal management through a single, unified package.

Technical Deep Dive

The Architecture of Integration: A Look Inside the 7-in-1 Module

The 7MBR15VKC120-50 is more than a collection of switches; it's a fully integrated power conversion system in a compact P626 package. This module consolidates three distinct functional blocks into a single substrate, offering a streamlined solution for motor control. What is the key advantage of a 7-in-1 PIM? It significantly reduces component count and simplifies the overall system design. The internal configuration includes:

- Three-Phase Converter: A full diode bridge for rectifying AC input voltage.

- Three-Phase Inverter: Six V-Series trench gate field-stop IGBTs with corresponding free-wheeling diodes (FWD) to drive the motor windings.

- Brake Chopper: An additional IGBT and FWD circuit for dissipating regenerative energy, providing controlled deceleration.

This high level of integration inherently minimizes stray inductance between stages, a common challenge in discrete designs that can lead to voltage overshoots. Furthermore, the inclusion of a built-in NTC thermistor provides a direct and accurate method for monitoring the module's operating temperature, a critical factor in ensuring long-term system reliability.

Industry Insights & Strategic Advantage

Driving Down Complexity in Modern Industrial Automation

In the competitive landscape of industrial automation, time-to-market and total cost of ownership are paramount. The design philosophy of the Fuji Electric 7MBR15VKC120-50 directly supports these objectives. By providing a pre-validated, all-in-one power stage, it allows engineering teams to bypass the complexities of selecting, matching, and laying out over a dozen discrete components. This approach is particularly valuable in the development of decentralized drives and compact servo systems, where board space and thermal density are primary design constraints. The module's architecture aligns with the industry trend of pushing more intelligence and power into smaller physical footprints, enabling more efficient and cost-effective automation solutions.

Success Stories / Deployment Snippets

From Concept to Commissioning: An Accelerated Design Path

Adopting the 7MBR15VKC120-50 fundamentally changes the power stage design workflow. An engineering team can move from schematic to a functional prototype more rapidly by eliminating the tedious process of discrete component layout and interconnect routing. Procurement is simplified to a single part number, and assembly is reduced to mounting and connecting one module instead of many individual devices. This streamlined path not only shortens the development timeline but also reduces the potential for assembly errors and improves manufacturing consistency, leading to a more reliable end product from the first build.

Key Parameter Overview

Core Specifications for Seamless System Integration

Understanding the key parameters of the 7MBR15VKC120-50 is essential for proper system design. The collector-emitter saturation voltage, or VCE(sat), is the forward voltage drop across the IGBT when it is fully "on." Think of it as the inherent resistance of a closed switch; a lower value indicates higher efficiency. With a typical VCE(sat) of 1.75V, this module minimizes conduction losses, reducing the amount of waste heat generated during operation. The thermal resistance from junction to case, Rth(j-c), acts like a bottleneck for heat flow. The low specified values for this module indicate an efficient thermal path, allowing heat from the silicon die to be transferred effectively to the heatsink, a crucial aspect detailed in any guide to decoding IGBT datasheets.

Download the Complete Datasheet

| Electrical & Thermal Characteristics (Ta = 25°C) | ||

|---|---|---|

| Inverter Section | ||

| Parameter | Symbol | Value |

| Collector-Emitter Voltage | Vces | 1200V |

| Continuous Collector Current (Tc=80°C) | Ic | 15A |

| Collector-Emitter Saturation Voltage (Ic=15A) | VCE(sat) | 1.75V (typ.) |

| Thermal Resistance (Junction-to-Case, per IGBT) | Rth(j-c) | 2.08°C/W |

| Converter Section | ||

| Repetitive Peak Reverse Voltage | VRRM | 1600V |

| Average Forward Current | IF(AV) | 15A |

| Brake Section | ||

| Collector-Emitter Voltage | Vces | 1200V |

| Continuous Collector Current (Tc=80°C) | Ic | 15A |

Intra-Series Comparison & Positioning

Positioning the 15A PIM Within the V-Series Family

The 7MBR15VKC120-50 serves as a highly capable solution for low-power three-phase motor applications. Its 15A rating is well-suited for drives typically in the 1.5kW to 2.2kW range. For systems that demand a higher power output while retaining the benefits of an integrated 7-in-1 topology, designers can look to other modules in the same family. For instance, the 7MBR25SA120-50 provides a clear upgrade path, offering a higher 25A current rating in a compatible package. This allows for scalability in product lines without requiring a complete redesign of the power stage layout, showcasing the flexibility of using IGBT modules as a platform-based solution.

Application Scenarios & Value

Enabling Compact and Cost-Effective Motor Control Systems

The high integration level of the 7MBR15VKC120-50 makes it a prime candidate for applications where space, assembly cost, and reliability are critical design factors. Its performance characteristics are optimized for the switching frequencies commonly found in industrial and commercial equipment.

- General-Purpose AC Inverters: The module's all-in-one nature is ideal for compact variable frequency drives (VFDs) used to control fans, pumps, and conveyor systems.

- Low-Power Servo Drives: In robotics and automated machinery, the module's small footprint enables the design of smaller, more integrated servo amplifiers.

- HVAC Systems: Provides a reliable and efficient power core for compressors and air handlers, where long-term operational reliability is essential.

With its all-in-one topology and a low VCE(sat) of 1.75V, this module is the optimal choice for cost-sensitive AC drives under 2.2kW.

Frequently Asked Questions

1. What are the main design advantages of using the 7MBR15VKC120-50 over discrete IGBTs and rectifiers?

The primary advantages are significantly reduced component count, a much simpler PCB layout, lower assembly costs, and improved reliability. By integrating all power stages, it minimizes parasitic inductance and ensures optimized thermal performance across all components within a single, factory-tested Power Integrated Module (PIM).

2. What is the function of the built-in thermistor and how should it be used?

The integrated NTC thermistor provides real-time temperature feedback from the module's substrate. This allows the system controller to monitor the module's thermal state accurately. It can be used to trigger thermal warnings, implement power derating to prevent overheating, or initiate a system shutdown in a fault condition, enhancing overall system safety and longevity.

3. What are the key considerations for heatsink mounting and thermal paste application for the P626 package to ensure reliability?

For optimal heat transfer, it is crucial to ensure the heatsink surface is flat and clean. A high-quality thermal interface material (TIM) should be applied in a thin, even layer across the module's baseplate to fill microscopic air gaps. Applying the correct mounting torque as specified in the datasheet is essential to ensure proper contact without inducing mechanical stress on the module.

Design & Integration Support

To fully leverage the capabilities of the 7MBR15VKC120-50 and streamline your design process, a deep understanding of its integrated features is key. Our team can provide the necessary documentation and technical data to help you assess its fit for your specific motor drive application. Evaluating this module could be the first step toward a more compact, reliable, and cost-effective power conversion design. For a broader view on the strategic choices in power electronics design, exploring resources that compare IPM vs. discrete IGBT solutions can provide valuable context.