Content last revised on November 15, 2025

## 6MBP150RS060: Fuji 6-in-1 IGBT Module for Inverter Control

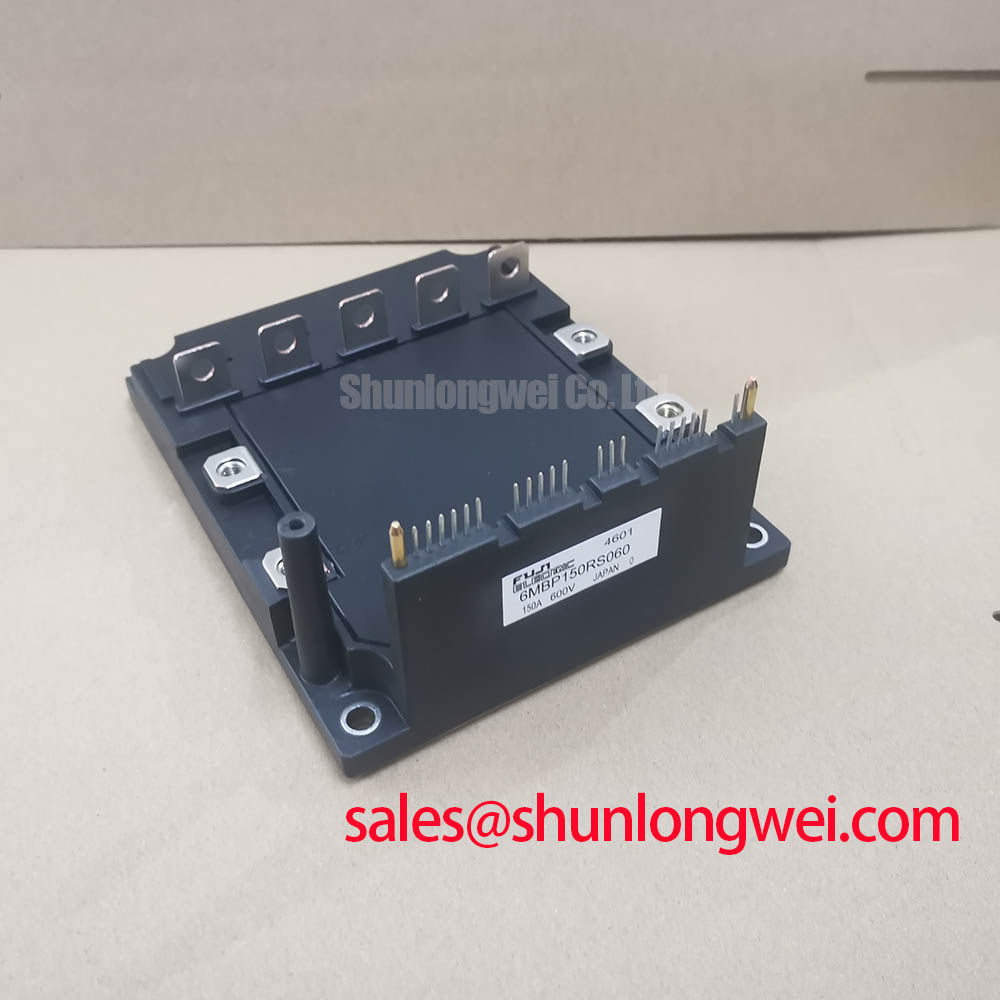

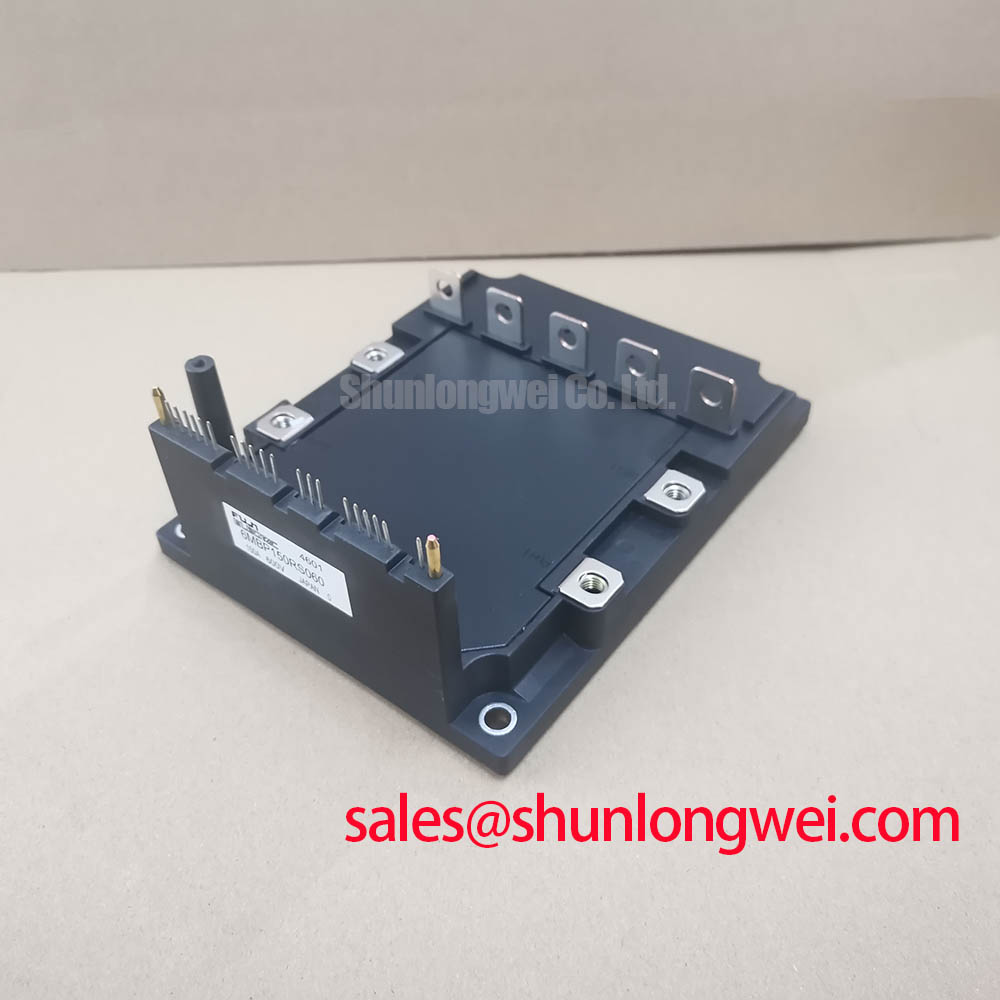

The 6MBP150RS060 from Fuji Electric is a 600V, 150A Intelligent Power Module (IPM) designed for simplifying and consolidating the power stages of three-phase inverter systems. It integrates six IGBTs in a bridge configuration, along with freewheeling diodes and gate drive circuitry, into a single compact package. This level of integration directly addresses the engineering challenge of reducing board space and assembly complexity in motor drives and power conversion applications. For designs where minimizing the Bill of Materials (BOM) and shortening assembly time are critical, the all-in-one nature of the 6MBP150RS060 provides a tangible advantage.

Intra-Series Comparison & Positioning

Within its product family, the 6MBP150RS060 is positioned as a comprehensive solution for mid-power applications. While individual discrete IGBTs may offer granular control over specific switching characteristics, this module prioritizes integration. Compared to other modules that might offer higher voltage or current ratings, the 6MBP150RS060 finds its niche in applications where a 600V/150A rating is sufficient, and the benefits of a pre-packaged, matched set of power devices and drivers outweigh the need for a custom-designed discrete solution. The inclusion of protection circuits for overcurrent and undervoltage simplifies the external supervisory circuitry required, further accelerating the design cycle. For systems requiring different power levels, related components like the 6MBP100RS120 offer alternative current and voltage ratings within a similar integrated framework.

Key Parameter Overview

To facilitate a clear technical assessment, the following table outlines the key parameters of the 6MBP150RS060, organized by functional category. These specifications are essential for performing accurate thermal and electrical simulations during the design phase. A complete understanding of these values is crucial for ensuring both performance and long-term reliability. For a comprehensive list of specifications, please refer to the official datasheet.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Absolute Maximum Ratings | ||||

| Collector-Emitter Voltage | VCES | - | 600 | V |

| Collector Current | IC | - | 150 | A |

| Collector Power Dissipation (per IGBT) | PC | - | 480 | W |

| Junction Temperature | Tj | - | +150 | °C |

| Electrical Characteristics | ||||

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 150A | 2.7 (Max) | V |

| FWD Forward Voltage | VF | IF = 150A | 3.0 (Max) | V |

| Thermal Characteristics | ||||

| Thermal Resistance (Junction to Case, per IGBT) | Rth(j-c) | - | 0.26 (Max) | °C/W |

Note: The parameters listed are for reference only.

Application Scenarios & Value

The integrated nature of the 6MBP150RS060 makes it highly suitable for a range of power conversion systems where space, assembly efficiency, and reliability are key considerations.

Driving Efficiency in Motor Control

This module is a strong candidate for industrial motor drives, including those for AC induction motors and brushless DC motors. Its 6-in-1 configuration simplifies the three-phase bridge topology required for these applications. By co-packaging the IGBTs and diodes, the parasitic inductances between components are minimized and controlled, leading to cleaner switching waveforms and potentially lower electromagnetic interference (EMI). For applications in robotics and factory automation, where precise and efficient motor control is paramount, this module provides a robust power core. You can explore more about the role of IGBTs in these systems in our guide on IGBTs in robotic servo drives.

Consolidating Power Conversion Designs

The 6MBP150RS060 is also well-suited for general-purpose inverters, small-scale uninterruptible power supplies (UPS), and welding power sources. What is the main benefit of its integrated drive circuits? It eliminates the need for engineers to design, source, and validate six separate gate drivers, significantly reducing the BOM and potential points of failure. The module's thermal resistance, Rth(j-c), can be thought of as the bottleneck in a pipe; a lower value means heat can escape more easily from the active silicon to the heatsink. The specified maximum of 0.26 °C/W for this module provides a solid basis for developing an effective thermal management strategy.

Technical Deep Dive

A Closer Look at the 6-in-1 Topology

The 6MBP150RS060 integrates a complete three-phase inverter bridge into a single module. This topology consists of six Insulated Gate Bipolar Transistors (IGBTs) and six co-packaged freewheeling diodes (FWDs). This high level of integration offers several engineering advantages over discrete solutions. Firstly, it ensures that the dynamic and static characteristics of all power switches are closely matched, which is critical for balanced phase currents and minimizing harmonics in motor drive applications. Secondly, the compact internal layout reduces stray inductance, which helps to suppress voltage overshoots during high-speed switching events.

Industry Insights & Strategic Advantage

In today's competitive landscape for industrial and commercial electronics, time-to-market and design reliability are critical differentiators. The use of highly integrated modules like the Fuji Electric 6MBP150RS060 aligns directly with these strategic goals. By abstracting the complexity of the power stage into a single, pre-verified component, engineering teams can allocate more resources to application-level software, control algorithms, and user interface development. This approach not only shortens the design cycle but also simplifies supply chain management and manufacturing processes, contributing to a lower total cost of ownership. This module is a prime example of the trend toward system-in-package solutions that enable faster innovation in power electronics. To better understand the decision-making process, consider our analysis of IPM vs. discrete IGBT solutions.

Frequently Asked Questions (FAQ)

What are the primary considerations when designing a heatsink for the 6MBP150RS060?

The key parameter for heatsink design is the thermal resistance from junction to case, Rth(j-c), specified as 0.26 °C/W maximum per IGBT. Your thermal design must ensure that the junction temperature (Tj) remains below the 150°C maximum rating under worst-case operating conditions (maximum current, ambient temperature, and switching frequency). This involves calculating total power loss (conduction and switching) and selecting a heatsink with a sufficiently low thermal resistance to ambient to dissipate the generated heat effectively.

How does the integrated gate driver in the 6MBP150RS060 simplify system design?

The built-in gate driver and protection circuits significantly reduce design complexity. Engineers do not need to develop separate circuits for gate signal amplification, level shifting, and implementing protection features like over-current and under-voltage lockout. This not only saves PCB space and reduces the component count but also eliminates the complex task of optimizing the gate drive loop for the specific IGBTs used, as this is pre-optimized within the Fuji Electric module.

For further technical inquiries or to discuss how the 6MBP150RS060 can fit into your specific application, please contact our engineering support team.