Content last revised on October 26, 2025.

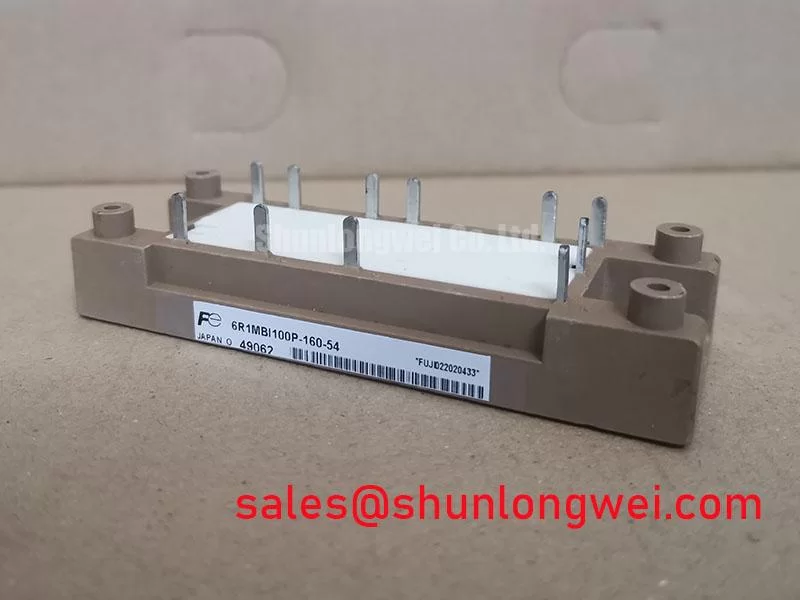

Fuji Electric 6R1MBI100P-160-54 P-Series IGBT Module

Engineered for High-Voltage Industrial Power Conversion

The Fuji Electric 6R1MBI100P-160-54 is a highly integrated power module designed for robust performance in demanding three-phase power conversion systems. This module provides a comprehensive solution by incorporating a three-phase converter diode bridge and a dynamic brake circuit into a single, compact package, streamlining system design and assembly. Key specifications include a 1600V repetitive peak reverse voltage and a 100A average output current, making it a formidable component for high-power applications. Its primary engineering benefits are simplified PCB mounting and enhanced system reliability, directly addressing the need for durable and efficient power stages in modern industrial equipment. For high-voltage motor drives requiring a robust front-end rectifier and braking chopper, the 6R1MBI100P-160-54 offers a functionally complete and reliable solution.

Key Parameter Overview

Decoding the Specs for System Reliability

The technical specifications of the 6R1MBI100P-160-54 are pivotal for engineers designing high-reliability power systems. The highlighted parameters below are critical for thermal management, fault tolerance, and ensuring the module operates within its safe limits.

| Parameter | Symbol | Condition | Value |

|---|---|---|---|

| Repetitive Peak Reverse Voltage | VRRM | - | 1600V |

| Non-Repetitive Peak Reverse Voltage | VRSM | - | 1760V |

| Average Output Current | Io | 50/60Hz Sine Wave, Tc=110°C | 100A |

| Surge Current (One Cycle) | IFSM | 50Hz | 1000A |

| I squared t | I²t | - | 4000 A²s |

| Operating Junction Temperature | Tj | - | -40 to +125°C |

Download the 6R1MBI100P-160-54 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in Industrial Drives and Power Supplies

The 6R1MBI100P-160-54 is engineered for applications where voltage overhead and operational reliability are paramount. Its 1600V rating provides a significant safety margin for systems connected to 575V or 690V AC lines, which are common in heavy industrial settings.

A high-fidelity engineering scenario for this module is in the front-end of a Variable Frequency Drive (VFD) controlling a high-inertia load, such as a large industrial fan or centrifuge. During deceleration, the motor acts as a generator, causing the DC link voltage to rise. The integrated dynamic brake circuit in the 6R1MBI100P-160-54 provides a controlled path to dissipate this regenerative energy, protecting the DC link capacitors and other components from overvoltage stress. The module's high surge current rating of 1000A is critical for withstanding inrush currents during startup without degradation. This integration of rectification and braking simplifies the overall power stage design, reduces component count, and enhances the system's robustness against line fluctuations and demanding load cycles. For systems operating on standard 400V lines with higher current demands, the 6MBI450U-120 offers a 1200V rating with significantly higher current handling capabilities.

- Inverters for Motor Drives

- AC and DC Servo Drive Amplifiers

- Uninterruptible Power Supplies (UPS)

Industry Insights & Strategic Advantage

Meeting the Demands for Power Density and Uptime

In the landscape of industrial automation, the drive towards higher power density and unwavering reliability places stringent demands on power conversion components. The 6R1MBI100P-160-54 directly addresses these trends. Its integrated design, which combines the converter and brake circuits into a single P.C. board mountable package, is a key enabler for creating more compact and cost-effective Servo Drive and VFD systems. This consolidation not only saves valuable cabinet space but also minimizes parasitic inductance and improves thermal interfacing compared to solutions using multiple discrete components. This design philosophy aligns with industry standards that prioritize both efficiency and operational safety, such as those outlined in IEC 61800-5 for adjustable speed electrical power drive systems.

Frequently Asked Questions (FAQ)

What is the primary benefit of the integrated converter and brake circuit design?

The integrated approach significantly simplifies system design and assembly. It reduces the number of components, minimizes wiring, lowers parasitic inductance, and provides a consolidated thermal footprint, which contributes to higher overall system reliability and a more compact end product.

What does the 1600V repetitive peak reverse voltage rating signify for an application?

A VRRM of 1600V provides a substantial safety margin for operation on 575V and 690V industrial power grids. This high breakdown voltage is crucial for ensuring long-term reliability in environments prone to voltage transients and line surges, directly contributing to equipment longevity.

How does the 100A current rating relate to real-world motor applications?

The 100A average output current rating (at a case temperature of 110°C) defines the module's capacity to continuously supply a three-phase load. This makes it suitable for powering AC induction motors in the approximate range of 45-55 kW (or 60-75 HP) on a 575V line, depending on the specific motor efficiency and service factor.

What is the role of the 4000 A²s I²t rating?

The I²t rating represents the module's thermal energy handling capability under a short, non-repetitive fault condition. It is a critical parameter for coordinating with upstream fuses or circuit breakers. A value of 4000 A²s ensures the diode bridge can survive significant fault currents for the brief period it takes for protective devices to open the circuit, preventing catastrophic module failure.

From a strategic perspective, the Fuji Electric 6R1MBI100P-160-54 provides system designers with a robust, integrated building block that enhances the reliability and power density of industrial power converters. Its high voltage rating and consolidated functionality offer a clear path to developing more resilient and compact drive systems, aligning with the core demands of modern industrial automation and power infrastructure. For more information on the manufacturer, visit Fuji Electric's power module resource page.