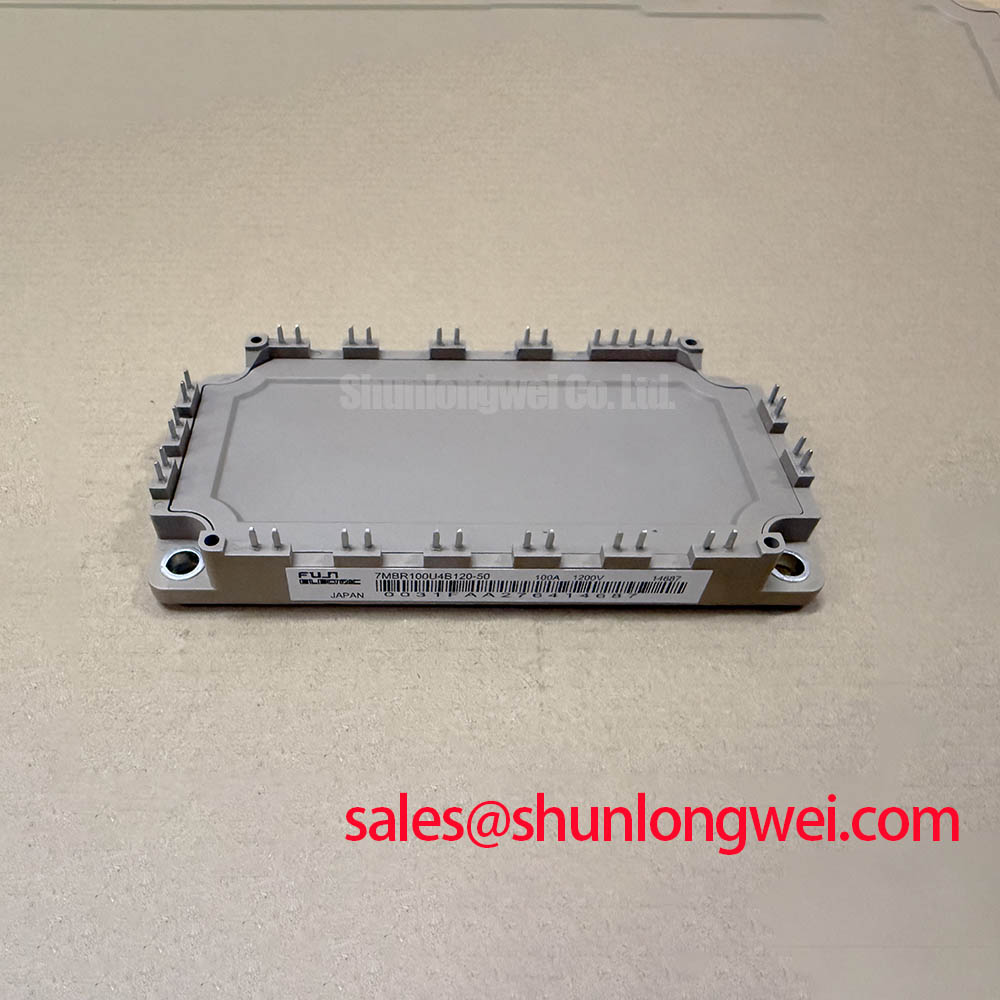

Fuji 7MBR100U4B120-50 | 1200V 100A V-Series Power Integrated Module (PIM)

The Fuji 7MBR100U4B120-50 is a highly integrated Power Integrated Module (PIM) engineered for demanding power conversion applications. As a cornerstone of Fuji Electric's renowned V-Series, this module combines a three-phase inverter, a brake chopper, and a three-phase converter bridge into a single, compact package. It is engineered for designers seeking to optimize system size, enhance reliability, and streamline assembly in applications up to the 45kW range.

Core Engineering Advantages

- System-in-a-Box Integration: Consolidates a 7-in-1 circuit (3-phase converter + brake + 3-phase inverter) into one module, significantly reducing component count, minimizing PCB complexity, and lowering overall system assembly costs.

- Optimized V-Series Performance: Leverages Fuji's 4th Generation V-Series IGBT and FWD (Freewheeling Diode) technology, which provides a meticulously balanced trade-off between low conduction losses and controlled switching characteristics.

- Enhanced Thermal Management: Features an integrated NTC thermistor, enabling real-time temperature monitoring directly at the substrate level for superior thermal protection and system longevity.

- High Reliability and Durability: Built on a proven platform known for its robustness, offering excellent power cycling capability and a high short-circuit withstand time, crucial for industrial environments.

Technical Deep Dive: The 7-in-1 PIM Advantage

The defining feature of the Fuji 7MBR100U4B120-50 is its 7-in-1 Power Integrated Module (PIM) topology. Unlike designs that require separate rectifier modules, a brake chopper, and an inverter stage, this device integrates all seven power switches into a single housing. This architectural choice delivers tangible engineering benefits. By minimizing the interconnects between power stages, stray inductance is inherently reduced, which helps mitigate voltage overshoots during high-speed switching. This simplifies the design of snubber circuits and improves overall electromagnetic compatibility (EMC) performance. Furthermore, the consolidated thermal footprint simplifies heat sink selection and mechanical assembly, making it an ideal solution for compact, power-dense systems.

Key Parameter Overview

The following table outlines the critical electrical and thermal characteristics that define the performance of the 7MBR100U4B120-50. For a complete dataset, designers should consult the official datasheet. Download the Fuji 7MBR100U4B120-50 Datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200V |

| Collector Current (IC) at TC=80°C | 100A |

| Collector-Emitter Saturation Voltage (VCE(sat)) typ. at IC=100A | 1.80V |

| Power Dissipation per IGBT (PC) at TC=25°C | 480W |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) per IGBT | 0.26 K/W |

| Short-Circuit Withstand Time (tsc) | ≥ 10µs (VCC = 600V, VGE = ±15V) |

Application Suitability and Value Proposition

The unique feature set of the Fuji 7MBR100U4B120-50 makes it an exceptional choice for a range of power conversion systems.

- Variable Frequency Drives (VFDs): The integrated brake chopper is essential for managing regenerative energy during motor deceleration, a common scenario in elevator, crane, and conveyor applications. The module's high integration simplifies the VFD's power core design.

- Servo Drives: For high-performance motion control, the module's soft-recovery freewheeling diode (FWD) minimizes recovery losses and reduces noise, enabling the precision required in modern robotic servo drives.

- Uninterruptible Power Supplies (UPS): In UPS systems, efficiency and reliability are paramount. The low VCE(sat) of the V-Series IGBTs reduces conduction losses, improving overall system efficiency and minimizing cooling requirements.

Frequently Asked Engineering Questions (FAQ)

1. What is the primary advantage of using this PIM over a discrete IGBT and diode solution?

The primary advantage is system integration. A PIM like the Fuji 7MBR100U4B120-50 drastically reduces design complexity, component count, and assembly time. It provides a pre-optimized thermal and electrical solution, reducing the risk of design errors related to PCB layout, parasitic inductance, and component matching. This leads to a faster time-to-market and often a lower total cost of ownership. For a broader look at the role of these components, explore our guide on IGBT modules as the backbone of power systems.

2. Does the 7MBR100U4B120-50 require a negative gate voltage for turn-off?

While the module can operate with a 0V turn-off signal, the datasheet specifies performance and short-circuit ratings using a bipolar gate drive (e.g., +15V/-15V). Using a negative gate voltage (typically -5V to -15V) is highly recommended in industrial applications. It provides a greater noise margin against dv/dt induced parasitic turn-on, ensuring more robust and reliable switching performance, especially in electrically noisy motor drive environments. For any specific design-in questions, please contact our technical team for support.