Content last revised on January 15, 2026

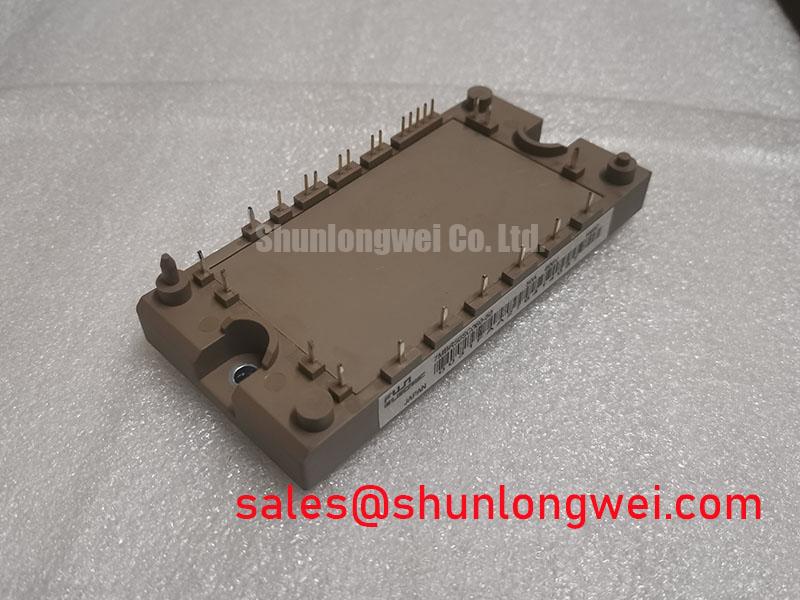

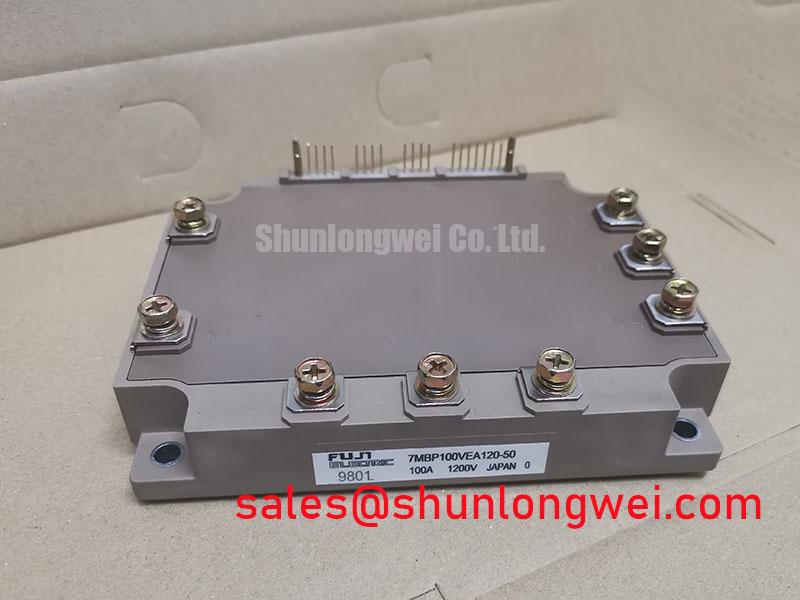

Fuji Electric 7MBR50SC060-50 | Compact PIM for High-Efficiency Power Conversion

The Fuji Electric 7MBR50SC060-50 is a highly integrated 600V, 50A Power Integrated Module (PIM) engineered to streamline the design of compact and efficient power conversion systems. As a 7-in-1 module, it combines a three-phase converter bridge, a three-phase inverter bridge, and a brake chopper with an NTC thermistor into a single, thermally efficient package. This level of integration is a decisive advantage for engineers developing systems where board space, assembly cost, and time-to-market are critical constraints. This device is an exemplary solution among modern IGBT modules, designed specifically for low to medium-power applications demanding high reliability.

Technical Deep Dive: Engineering for Performance and Reliability

The performance of the 7MBR50SC060-50 is rooted in Fuji Electric's advanced semiconductor technology and intelligent package design. Two features stand out for their direct impact on system performance.

- 6th Generation FS Trench IGBT Technology: At the heart of the inverter stage are Fuji’s 6th generation Field-Stop (FS) Trench IGBTs. This technology masterfully balances the trade-off between conduction losses (low VCE(sat)) and switching losses. For the design engineer, this translates directly to lower overall power dissipation. The result is reduced heatsink requirements, enabling higher power density and a more compact final product without compromising thermal stability.

- Integrated NTC Thermistor: Effective thermal management is non-negotiable for power module longevity. This PIM includes a built-in NTC thermistor with a direct thermal path to the module's baseplate. This provides a precise, real-time method for monitoring operating temperature, allowing the control system to implement over-temperature protection or dynamic performance scaling, drastically improving the overall system reliability and preventing catastrophic failure.

Application Scenarios & Engineering Value

The unique combination of integration and performance makes the Fuji Electric 7MBR50SC060-50 an ideal component for several demanding applications.

- Small to Medium Motor Drives: For variable frequency drives (VFDs) in the sub-15kW class, this PIM is a game-changer. It consolidates the entire power stage, significantly reducing the bill of materials (BOM), minimizing parasitic inductance, and simplifying the PCB layout and assembly process.

- Industrial Automation and Robotics: In robotic servo drives and CNC machines, precise control and high reliability are paramount. The integrated brake chopper effectively manages regenerative energy during deceleration, preventing DC bus overvoltage and ensuring stable, predictable operation.

- Uninterruptible Power Supplies (UPS): The module's robust 7-in-1 topology, which includes the rectifier front-end and inverter output stage, provides a complete power conversion block for online UPS systems, ensuring a clean and reliable power supply for critical loads.

Key Parameter Overview: 7MBR50SC060-50

The following table outlines the critical electrical and thermal characteristics. For complete specifications and application notes, please Download the Datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 600 V |

| Collector Current (I_C) at T_C = 80°C | 50 A |

| Collector-Emitter Saturation Voltage (V_CE(sat), Typ. at I_C = 50A) | 1.70 V |

| Maximum Power Dissipation (P_C) per IGBT | 200 W |

| Maximum Junction Temperature (T_j(max)) | 175 °C |

| Topology | 3-Phase Converter + 3-Phase Inverter + Brake Chopper + NTC |

Industry Insight: The Strategic Value of Power Integration

The power electronics industry continues to trend towards higher power density and reduced system costs. The traditional approach of using discrete components for the rectifier, inverter, and brake functions presents significant challenges in layout, assembly, and thermal management. A PIM (Power Integrated Module) like the 7MBR50SC060-50 directly addresses these challenges. By co-packaging optimized components in a single module, it offers a pre-validated power core that reduces design cycle time, lowers manufacturing complexity, and enhances system reliability by minimizing interconnections and stray inductance. This makes it a strategically superior choice for competitive, modern power conversion designs.

Frequently Asked Questions (FAQ)

What are the primary considerations for the gate drive design for this PIM?

A robust gate drive is crucial for optimal performance. We recommend a dual-supply voltage of +15V / -15V to ensure fast, clean turn-on and to provide a strong negative bias for turn-off noise immunity. It's essential to use individual gate resistors for each of the six inverter IGBTs to dampen potential oscillations. For a deeper understanding of robust driver implementation, review these practical tips for gate drive design.

How does the integrated brake chopper benefit my application?

In motor drive applications, when a motor decelerates rapidly, it acts as a generator, feeding energy back into the DC bus. The integrated brake chopper provides a controlled path to dissipate this regenerative energy through an external braking resistor. This prevents the DC bus voltage from rising to dangerous levels, protecting the inverter and other components from overvoltage damage and ensuring system stability during dynamic load changes.