Content last revised on January 20, 2026

7MBR100VN120-50 IGBT: Efficiency in a 7-in-1 Package

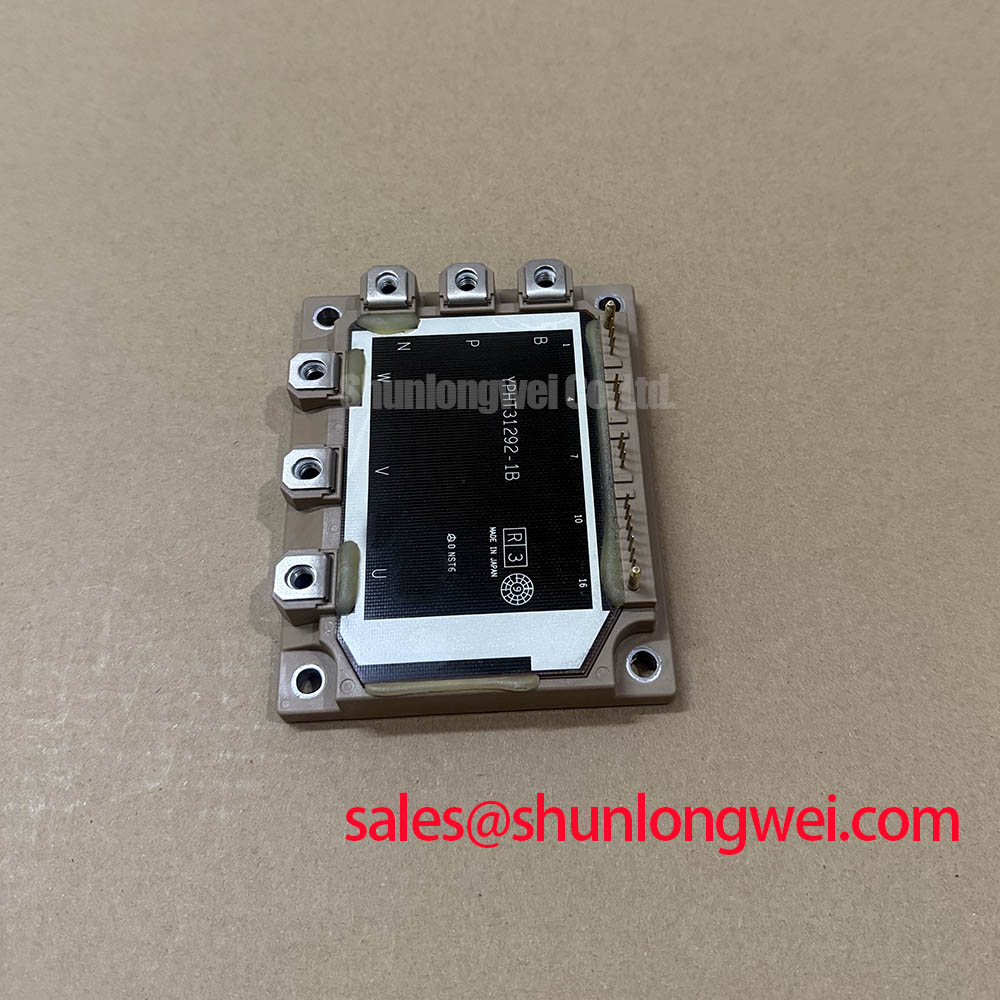

Driving superior efficiency in compact power systems, the Fuji Electric 7MBR100VN120-50 integrates a full converter-inverter-brake topology. With its core specifications of 1200V | 100A | VCE(sat) 1.70V (Typ), this V-Series module provides minimal conduction losses and simplified thermal management. For engineers asking how to reduce component count in variable frequency drives, this module's high integration level offers a direct path to a smaller footprint and streamlined assembly, consolidating seven power stages into a single, thermally efficient housing.

Engineering Questions on the 7MBR100VN120-50

What are the primary contributors to the 7MBR100VN120-50's power efficiency?

The module's efficiency stems primarily from the low collector-emitter saturation voltage (VCE(sat)) of its 6th generation V-Series IGBTs, which minimizes heat generated during the on-state (conduction losses). This is complemented by optimized switching characteristics that reduce energy loss during on/off transitions, a critical factor in higher-frequency applications like modern motor drives.

How does the integrated NTC thermistor benefit system design?

The built-in NTC thermistor provides a direct, real-time temperature reading from the module's substrate. This allows for precise over-temperature protection, preventing thermal runaway and enhancing long-term operational reliability. It simplifies the external monitoring circuitry, reducing both component count and potential points of failure in the thermal management system.

Is the 7MBR100VN120-50 suitable for paralleling to achieve higher current output?

While paralleling IGBT modules is a common practice, it requires careful engineering consideration. Datasheets for modules like this one provide characteristics such as the positive temperature coefficient of VCE(sat), which is essential for thermal stability in parallel configurations. Designers must ensure meticulous gate drive symmetry and busbar layout to guarantee balanced current sharing. For a deeper dive into this topic, explore this guide on IGBT Paralleling.

Meeting Modern Efficiency Mandates

In an industrial landscape driven by stringent energy regulations and the rising cost of electricity, component-level efficiency is no longer an option but a requirement. The 7MBR100VN120-50 is situated to address this challenge directly. Its design focuses on reducing the total power loss profile, which is the sum of conduction and switching losses. This enables the end-equipment, such as a Variable Frequency Drive (VFD), to meet or exceed international efficiency standards like IE3/IE4 for motor systems. A lower power loss translates directly into reduced operational costs and a smaller carbon footprint over the system's lifetime, aligning with corporate sustainability goals and market demands for greener technology.

Core Applications: Powering Compact and Efficient Drives

The highly integrated 7-in-1 topology of the Fuji Electric 7MBR100VN120-50 makes it a cornerstone component for systems where space, assembly cost, and energy efficiency are critical design constraints. Its balanced performance characteristics are particularly well-suited for:

- AC Motor Drives & Servo Drives: The module contains all necessary power stages—a three-phase rectifier, a three-phase inverter, and a brake chopper—to control induction or servo motors in the 15 kW to 22 kW power class. Its low VCE(sat) ensures minimal heat dissipation, crucial for compact, fan-cooled, or sealed drive enclosures.

- General Purpose Inverters: From industrial pumps and fans to conveyor systems, the module provides a robust and reliable power core, simplifying the overall system architecture.

- Uninterruptible Power Supplies (UPS): The module's efficiency and integrated nature support the design of compact online UPS systems, where minimizing standby power loss is essential for a low Total Cost of Ownership (TCO).

What is the key benefit of its low VCE(sat)? Reduced power loss, leading to lower operating temperatures and higher system reliability.

For motor drive applications demanding high efficiency and a compact form factor, the 7MBR100VN120-50 is a leading solution due to its low 1.70V typical VCE(sat).

Deployment Focus: A Case for Integrated Efficiency

Consider the design of a mid-power industrial conveyor system. Using discrete components for the rectifier, inverter, and brake circuits would necessitate multiple heatsinks, complex wiring, and a larger control board. This increases assembly time, potential points of failure, and the overall system footprint. By deploying the 7MBR100VN120-50, a design team can consolidate these seven semiconductor functions onto a single, thermally optimized baseplate. This not only simplifies the mechanical layout but also standardizes the thermal interface, making heat dissipation more predictable and manageable. The result is a more compact, cost-effective, and reliable motor controller that can be brought to market faster. For those evaluating different power architectures, understanding the tradeoffs between integrated and discrete solutions is vital, a topic further explored in our analysis of IPM vs. discrete IGBTs.

A Closer Examination of V-Series Technology

The performance of the 7MBR100VN120-50 is anchored in Fuji Electric's 6th generation V-Series trench gate field-stop IGBT technology. This semiconductor structure is engineered to optimize the trade-off between on-state voltage drop and switching speed. The low VCE(sat) is a direct result of this advanced chip design, behaving like a highly efficient valve for electrical current—when open, it presents very little resistance, thus wasting minimal energy as heat. Think of it as a water valve that opens almost completely, allowing maximum flow with minimal pressure drop. This characteristic is fundamental to reducing conduction losses, which are often the dominant loss factor in motor drives operating at lower to medium frequencies. The module's construction ensures these benefits translate into tangible system-level performance gains. For a foundational understanding of how these components function, see our guide on deconstructing the IGBT.

Benchmarking for Informed Decisions

When evaluating power modules, engineers must compare key parameters to align the component's strengths with application requirements. The 7MBR100VN120-50 presents a specific profile that can be assessed against other options. For instance, designers might compare it with modules offering higher current ratings or different internal topologies. For systems requiring greater power handling, the 7MBR150VN120-50 provides a similar 7-in-1 configuration with a 150A rating. The choice between these depends on a careful analysis of the load profile, thermal budget, and cost targets of the end application. This data-driven approach ensures the selected module is not over-specified or under-specified, providing the optimal balance of performance and value.

Core Specifications of the 7MBR100VN120-50

The following table highlights the key performance indicators for the 7MBR100VN120-50, extracted directly from the official manufacturer's datasheet. These parameters form the basis for electrical and thermal simulations and are critical for a successful system design. For complete details, please refer to the product documentation.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200V |

| Collector Current, DC (Ic) - Inverter | 100A (Tc=80°C) |

| Collector-Emitter Saturation Voltage (VCE(sat)) - Inverter, Typ. | 1.70V (Ic=100A) |

| Forward Voltage (Vf) - FWD, Typ. | 1.65V (If=100A) |

| Thermal Resistance (Rth(j-c)) - Inverter IGBT | 0.23 K/W |

| Operating Junction Temperature (Tj) | +150°C (Max) |

The strategic integration of V-Series IGBT technology within the 7MBR100VN120-50 paves the way for the next generation of power conversion systems. As industries continue to pursue higher power densities and greater energy savings, components that offer a superior efficiency-to-cost ratio will become increasingly critical. This module represents a forward-looking solution, enabling designers to build systems that are not only powerful and compact today but also compliant with the energy standards of tomorrow.