Fuji Electric 7MBR75VZ120-50: The Integrated Power Core for Compact, High-Reliability Motor Drives

Introduction: A Strategic Overview

Defining a New Standard for Integrated Power Design

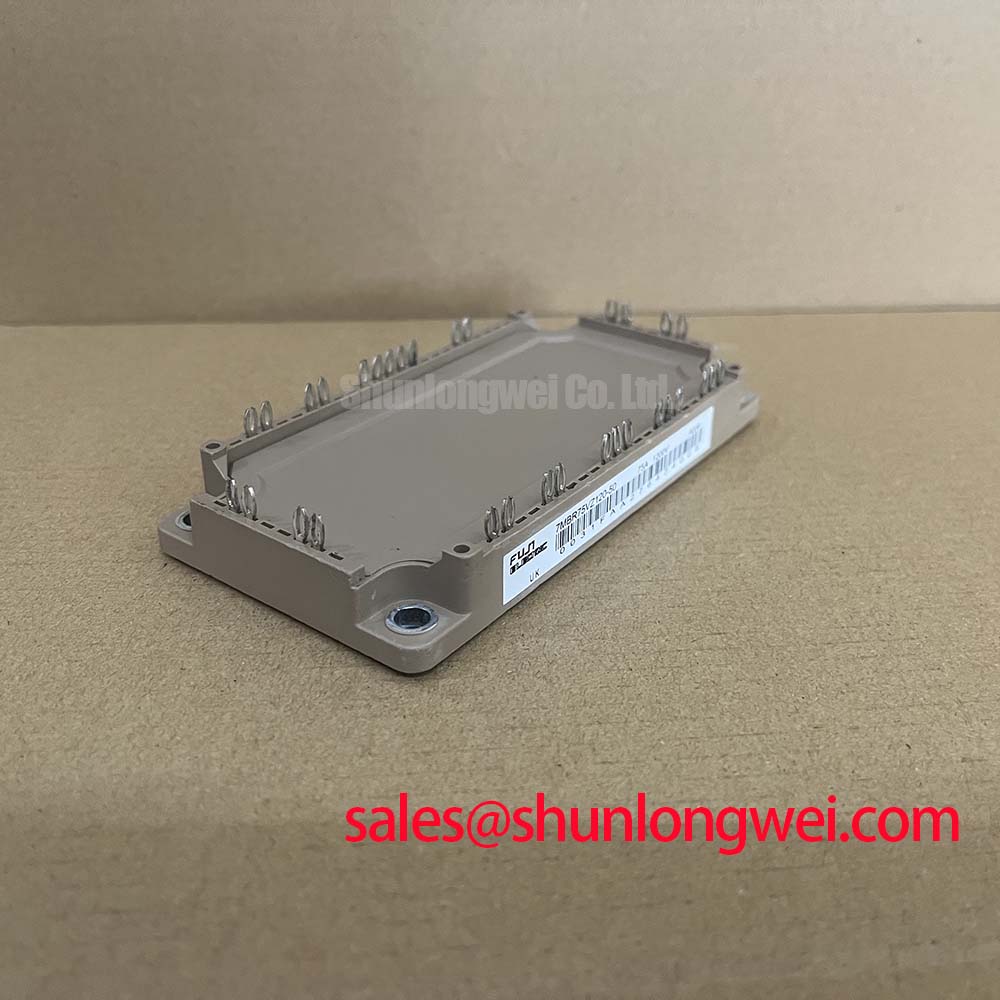

The Fuji Electric 7MBR75VZ120-50 is a highly integrated 7-in-1 intelligent power module designed to streamline the development of compact and efficient motor control systems. This module consolidates a three-phase converter, a three-phase inverter, and a brake chopper into a single, thermally efficient package, providing a robust power stage solution. With its core specifications of 1200V | 75A | VCE(sat) 2.1V typ., it offers a compelling combination of performance and integration. Key engineering benefits include significantly reduced component count and simplified thermal management through an integrated NTC thermistor. This addresses the critical challenge of achieving high power density without compromising on system-level reliability in modern industrial automation. For compact motor drives up to 30kW requiring integrated braking and thermal feedback, the 7MBR75VZ120-50 is the optimal design choice.

Application Scenarios & Value

System-Level Benefits in Integrated Motion Control Applications

The 7MBR75VZ120-50 is engineered to serve as the core power conversion block in a variety of demanding applications where space, efficiency, and reliability are paramount. Its all-in-one architecture makes it an exceptional fit for general-purpose inverters, vector control drives, and AC servo drives that power industrial machinery.

Consider the engineering challenge of designing a compact servo drive for a multi-axis CNC machine or robotic arm. PCB real estate is extremely limited, and thermal management is complex. The 7MBR75VZ120-50 directly solves this by replacing up to seven discrete IGBTs, three rectifier diodes, and their associated gate drive and protection circuits with a single module. This integration not only shrinks the final product size but also minimizes parasitic inductance and simplifies assembly, contributing to improved electrical performance and manufacturing yield. The built-in brake chopper circuit is essential for controlling motor deceleration in high-inertia loads, a common requirement in motion control systems, by safely dissipating regenerative energy through a braking resistor.

- Variable Frequency Drives (VFDs): Simplifies the power stage of compact drives used for pumps, fans, and conveyors.

- AC Servo Drives & Robotics: Delivers the high power density and integrated braking required for precise motion control.

- Uninterruptible Power Supplies (UPS): Provides a reliable, integrated solution for the inverter stage.

- Industrial Automation Systems: Serves as a versatile power module for a range of automated equipment.

For systems requiring lower current handling, the related 7MBR50VP120-50 offers a 50A alternative within the same family, while designs needing higher capacity may evaluate the 7MBR100VX120-50 for 100A capability.

Key Parameter Overview

Decoding the Datasheet for High-Density Drive Design

The technical specifications of the 7MBR75VZ120-50 are tailored for balanced performance in motor drive applications. The parameters below, drawn from the official datasheet, highlight its capabilities in terms of electrical ruggedness, efficiency, and thermal characteristics. The low saturation voltage is particularly important; it's analogous to having less friction in a mechanical system—less energy is wasted as heat during operation, which directly translates to higher inverter efficiency and a smaller, more cost-effective heatsink.

| Parameter | Symbol | Value | Conditions |

|---|---|---|---|

| Collector-Emitter Voltage | Vces | 1200 V | - |

| Continuous Collector Current (Inverter) | Ic | 75 A | Tc = 80°C |

| Collector-Emitter Saturation Voltage (Inverter) | VCE(sat) | 2.1 V (Typ) / 2.7 V (Max) | Ic = 75 A, Tj = 125°C |

| Total Power Dissipation | Pc | 390 W | Per IGBT, Tc = 25°C |

| Thermal Resistance (Junction-to-Case) | Rth(j-c) | 0.32 °C/W | Inverter IGBT |

| NTC Thermistor Resistance | R25 | 5 kΩ | T = 25°C |

Download the 7MBR75VZ120-50 datasheet for detailed specifications and performance curves.

Technical Deep Dive

Architectural Advantages of the 7-in-1 Configuration

The "7-in-1" designation of the 7MBR75VZ120-50 refers to its comprehensive integration of three distinct power stages into a single module. This architecture includes a three-phase diode bridge for AC-to-DC conversion, a full three-phase IGBT bridge for the DC-to-AC inverter stage, and an additional IGBT with a free-wheeling diode for the dynamic braking chopper. This level of consolidation is a key enabler for modern, power-dense designs.

A critical, yet often overlooked, feature is the integrated NTC thermistor. Its inclusion provides a direct and accurate measurement of the module's substrate temperature, which is a close proxy for the IGBT junction temperatures. In a Variable Frequency Drive (VFD), the control system can use this feedback to implement precise over-temperature protection. This is far superior to relying on external heatsink sensors, which react slower and less accurately. By knowing the module's actual temperature, the drive can intelligently derate its output power under heavy load conditions instead of an abrupt shutdown, leading to more robust and reliable system operation.

Technical FAQ for the 7MBR75VZ120-50 Module

What is the primary benefit of the V-Series IGBT chip technology used in this module?The Fuji Electric V-Series technology is engineered to optimize the trade-off between conduction losses (VCE(sat)) and switching losses. This results in higher overall efficiency across a wide range of operating frequencies, reducing waste heat and easing thermal design requirements for the end system.

How does the integrated NTC thermistor improve system reliability?It provides a direct, real-time feedback loop to the system's microcontroller for thermal monitoring. This allows for the implementation of sophisticated over-temperature protection, preventing the IGBTs from exceeding their safe operating limits and significantly reducing the risk of field failures due to thermal runaway.

What is the function of the integrated brake chopper?The brake chopper is used in motor drive applications to manage regenerative energy. When a motor decelerates, it acts as a generator, sending power back to the DC bus. The chopper circuit diverts this energy to an external braking resistor, preventing the DC bus voltage from rising to dangerous levels and protecting the module and other components.

Is this module suitable for high-frequency switching applications?The 7MBR75VZ120-50 is optimized for typical motor drive frequencies, generally in the range of 2 kHz to 15 kHz. While it features soft-switching characteristics, designers should consult the datasheet's Eon and Eoff energy loss curves to model performance and ensure thermal stability at higher Pulse Width Modulation (PWM) frequencies.

Strategic Considerations for System Design

Integrating the 7MBR75VZ120-50 into a power system offers a strategic path toward reducing both development time and total cost of ownership. The module's high level of integration simplifies not only the hardware design but also the supply chain by consolidating multiple part numbers into one. This streamlined approach, combined with the embedded thermal sensing for enhanced reliability, aligns perfectly with the industry's push for more compact, robust, and cost-effective power conversion solutions. For engineering teams focused on accelerating their time-to-market for next-generation Variable Frequency Drives (VFDs) and servo systems, this module represents a significant building block for competitive advantage.