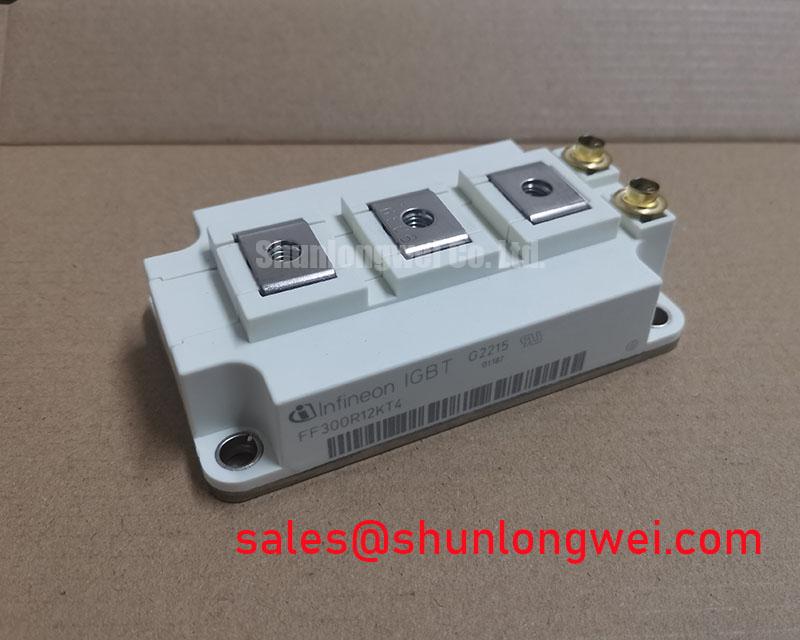

FF300R12KS4 | 1200V 300A IGBT Module for High-Efficiency Power Conversion

An In-Depth Engineering Review of the FF300R12KS4 IGBT Module

Content last revised on October 5, 2025.

The Infineon FF300R12KS4 is a 1200V, 300A dual IGBT module engineered to deliver superior power conversion efficiency and robust operational reliability. Leveraging advanced TRENCHSTOP™ IGBT3 technology, this module provides an optimized balance of low conduction and switching losses, crucial for demanding high-frequency applications. Key specifications include: 1200V | 300A | VCE(sat) 1.70V (typ). This translates directly to tangible engineering benefits, including a significantly reduced thermal load and enhanced system durability under fault conditions. For engineers designing high-performance inverters, the primary question is how to achieve higher power density without compromising on efficiency. The FF300R12KS4 directly addresses this by minimizing energy loss during operation, which allows for more compact thermal management solutions. For motor drives and solar inverters operating up to 20kHz, the FF300R12KS4's low switching energy is the optimal choice for minimizing cooling system costs.

Key Parameter Overview

Decoding the Specs for Efficient Power Switching

The technical specifications of the FF300R12KS4 are foundational to its performance in high-power systems. The values below, sourced from the official datasheet, highlight the key metrics that enable its efficiency and robustness. Particular attention should be given to the low collector-emitter saturation voltage and the optimized switching energies.

| Parameter | Symbol | Condition | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | Tvj = 25°C | 1200 V |

| Continuous Collector Current | IC nom | TC = 100°C | 300 A |

| Collector-Emitter Saturation Voltage | VCE sat | IC = 300 A, VGE = 15 V, Tvj = 25°C | 1.70 V (typ.) |

| Total Switching Energy | Ets | IC = 300 A, VCE = 600 V, VGE = ±15 V, Tvj = 125°C | 31.00 mJ (typ.) |

| Short Circuit Withstand Time | tSC | VGE ≤ 15 V, VCC = 800 V, Tvj ≤ 150°C | 10 µs |

| Thermal Resistance, Junction to Case | RthJC | per IGBT | ≤ 0.075 K/W |

| Maximum Junction Temperature | Tvj max | - | 150 °C |

Download the FF300R12KS4 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in High-Frequency Power Conversion

The FF300R12KS4 IGBT module is engineered for applications where efficiency and thermal performance are non-negotiable. Its low total switching energy (Ets) makes it exceptionally well-suited for systems operating at higher switching frequencies.

Consider the design of a modern Variable Frequency Drive (VFD) for industrial motor control. A key engineering challenge is managing the heat generated by the power stage, which directly impacts the VFD's size, cost, and reliability. The low Ets of the FF300R12KS4 means less energy is dissipated as heat each time the IGBT turns on and off. This reduction in waste heat can be compared to a high-performance engine that converts more fuel into power instead of heat. For a system designer, this allows for the use of a smaller, less expensive heatsink or a higher power output within the same thermal envelope, contributing to a more compact and cost-effective overall system design.

Core application areas include:

- Industrial Motor Drives

- Solar Inverters

- Uninterruptible Power Supply (UPS) systems

- Welding Power Supplies

- High-Power Switched-Mode Power Supplies (SMPS)

While this module is optimized for 300A applications, for systems requiring higher current handling in a similar voltage class, the CM600DX-24T offers a 600A rating. What defines the FF300R12KS4's efficiency? Its TRENCHSTOP™ IGBT3 technology minimizes both conduction and switching losses.

Frequently Asked Questions (FAQ)

What is the primary benefit of the TRENCHSTOP™ IGBT3 technology used in the FF300R12KS4?

The core advantage of Infineon TRENCHSTOP™ IGBT3 is the significant reduction in both conduction losses (due to a low VCE(sat)) and switching losses. This dual optimization results in higher overall inverter efficiency, which reduces operating costs and simplifies thermal management, a critical factor in power-dense designs.

How does the positive temperature coefficient of VCE(sat) benefit system design?

The positive temperature coefficient means that as the IGBT heats up, its on-state resistance slightly increases. This characteristic is crucial for stable parallel operation. It naturally forces current to share more evenly among parallel-connected modules without the need for complex balancing circuits, simplifying the design of high-power systems that require multiple modules. How does the positive VCE(sat) temperature coefficient help? It simplifies paralleling of modules for higher power output.

How does the module's Rth(j-c) of 0.075 K/W impact heatsink selection?

The thermal resistance from junction to case (Rth(j-c)) is a measure of how effectively heat can be transferred from the silicon chip to the module's baseplate. A lower value, like the 0.075 K/W of the FF300R12KS4, signifies superior heat transfer. This allows engineers to either use a smaller, more economical heatsink for a given power dissipation or to operate the module at a higher power level while maintaining a safe junction temperature, directly improving the system's power density.

Is the FF300R12KS4 suitable for hard-switching applications with high dv/dt?

Yes. The module is designed with an optimized Emitter Controlled 3 diode that exhibits soft recovery behavior. This characteristic is essential in hard-switching topologies as it minimizes voltage overshoots and oscillations during diode turn-off, which in turn reduces electromagnetic interference (EMI) and improves the overall reliability of the system. For a full analysis, it is essential to review the IGBT datasheets.

Industry Insights & Strategic Advantage

Meeting Future Demands for Power Density and Efficiency

The ongoing push towards industrial automation (Industry 4.0) and renewable energy generation places stringent demands on power electronics. Regulatory standards, such as those related to energy efficiency for motor drives (e.g., IEC 61800-9-2), are continuously tightening. The FF300R12KS4, with its foundation in low-loss TRENCHSTOP™ IGBT3 technology, provides a strategic advantage for designers aiming to meet and exceed these evolving requirements. Its ability to operate efficiently at higher frequencies supports the trend of miniaturization in power converters, as it allows for smaller magnetic components and filters. This positions the FF300R12KS4 not just as a component for today's systems, but as an enabling technology for next-generation, power-dense solutions in the solar and industrial sectors.

Strategic Outlook

Integrating the FF300R12KS4 into a power conversion system is a forward-looking decision. Its core technology from a market leader like Infineon is engineered to address the fundamental design challenges of reducing energy waste and maximizing power output per unit volume. For organizations focused on developing competitive and compliant high-power systems, this module provides a reliable and high-performance foundation that supports long-term product roadmaps centered on efficiency, power density, and operational robustness.