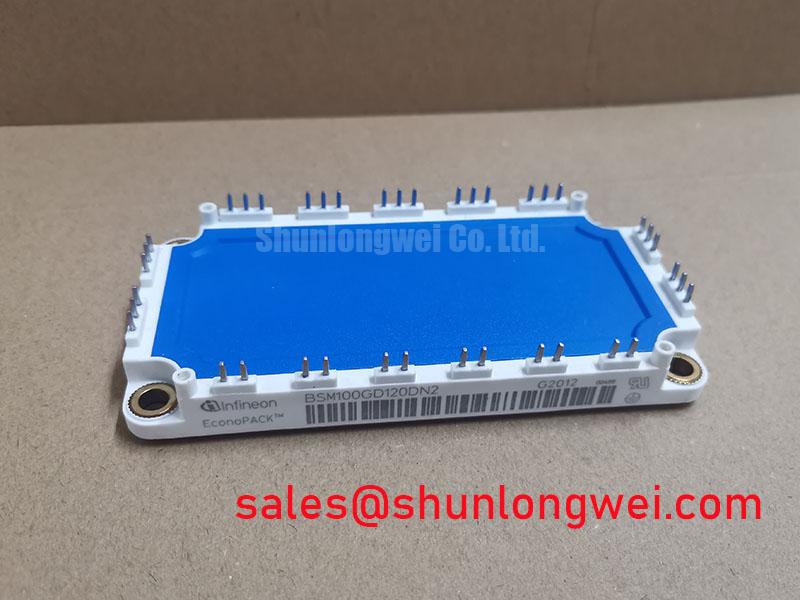

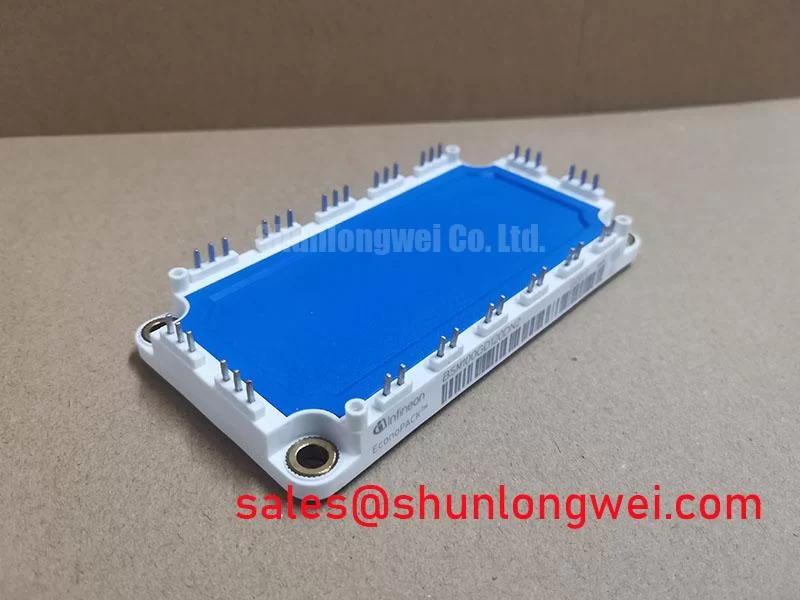

Infineon BSM100GD120DN2 | A Robust Half-Bridge for High-Efficiency Power Conversion

The Infineon BSM100GD120DN2 is a workhorse 1200V, 100A dual IGBT module engineered for demanding power conversion applications. Housed in a standard industrial package, this half-bridge module provides a foundational building block for creating high-reliability three-phase inverters, motor controllers, and power supplies. It strikes a crucial balance between low power losses, exceptional thermal performance, and the ruggedness required for modern industrial automation and renewable energy systems.

Technical Deep Dive: The Core of Performance

-

Advanced IGBT4 Trench and Field-Stop Technology

The Principle: At the heart of the BSM100GD120DN2 lies Infineon's proven IGBT4 Trench Field-Stop technology. This structure significantly reduces the collector-emitter saturation voltage (Vce(sat)), directly cutting down on conduction losses when the device is active. The integrated field-stop layer allows for a thinner silicon design, which minimizes switching losses (Eon/Eoff) and enables a positive temperature coefficient for Vce(sat), a critical feature for stable operation.

The Value: For system designers, this translates directly into higher inverter efficiency, reduced heat dissipation requirements (allowing for smaller, more cost-effective heatsinks), and safer paralleling of modules for higher power output.

-

Integrated Soft-Recovery Freewheeling Diode

The Principle: Each IGBT within the BSM100GD120DN2 is co-packaged with an emitter-controlled freewheeling diode (FWD) optimized for "soft" recovery characteristics. This means the diode transitions from a conducting to a blocking state smoothly, suppressing the voltage overshoots and high-frequency oscillations that often plague hard-switching circuits.

The Value: This feature simplifies the engineering challenge of electromagnetic compatibility (EMC). It results in lower radiated and conducted EMI, often reducing the need for extensive filtering and complex snubber circuits, leading to a more reliable and cost-effective final product.

Diverse Applications, Tangible Benefits

The versatility of the BSM100GD120DN2 makes it a prime choice across various industries, where its technical strengths solve specific challenges:

- Industrial Motor Drives & Servo Control: In precision automation, the module's low losses reduce heat build-up within the drive cabinet, enhancing system longevity. Its fast switching enables high-frequency PWM control for smoother motor operation and improved torque response.

- Uninterruptible Power Supplies (UPS): Efficiency is paramount in UPS systems to minimize operating costs. The module’s low Vce(sat) contributes directly to a higher overall system efficiency, ensuring critical loads are protected with minimal energy waste.

- Solar & Wind Power Inverters: The module’s robust construction and excellent thermal management capabilities ensure reliable energy harvesting, even in harsh outdoor environments with fluctuating temperatures.

- Welding Equipment: Modern inverter welders demand components that can handle high pulse currents and rapid switching. This IGBT module provides the speed and ruggedness needed to create a stable, controllable welding arc.

Key Technical Parameters

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200 V |

| Continuous Collector Current (IC) @ TC=80°C | 100 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) typ. @ IC=100A, Tj=125°C | 2.10 V |

| Maximum Junction Temperature (Tj max) | 150 °C |

Selection & Design Considerations: Half-Bridge vs. PIM

Engineers often weigh the benefits of a discrete half-bridge topology like the BSM100GD120DN2 against fully integrated Power Integrated Modules (PIMs) that contain a complete three-phase bridge. While PIMs offer compactness, using three individual half-bridge modules provides superior design flexibility. This approach allows for optimized PCB layouts, better thermal spreading across a larger heatsink area, and the ability to construct more complex topologies like multi-level inverters. For systems above 15-20 kW, the modular approach often yields better thermal and electrical performance.

Frequently Asked Questions (FAQ)

- Can multiple BSM100GD120DN2 modules be connected in parallel for higher current?

Yes, this is a common practice. The positive temperature coefficient of VCE(sat) provides a natural tendency for current to balance between parallel modules. However, achieving reliable performance requires meticulous design, including symmetrical PCB layouts for power paths and gate drive signals to ensure simultaneous switching. For detailed guidance, reviewing an application note on IGBT paralleling is highly recommended. - What is the most critical factor for mounting this module to a heatsink?

The most critical factor is achieving a low thermal resistance path. This involves using a high-quality thermal interface material (TIM) on a flat (typically