Content last revised on January 29, 2026

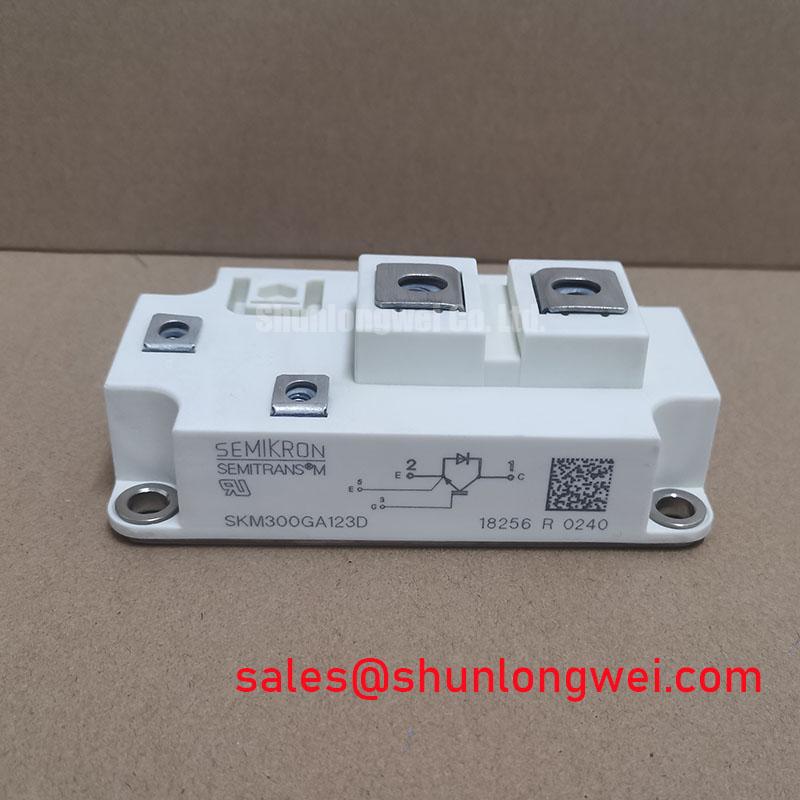

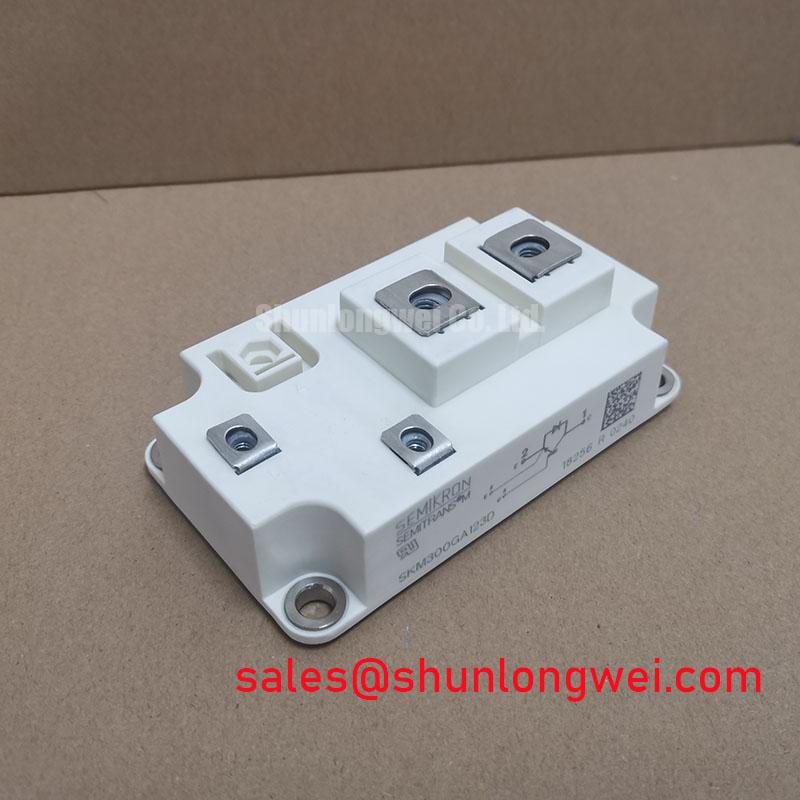

SKM300GA123D SEMITRANS 2 IGBT Module: Engineering for Thermal Reliability and Simplified Integration

Introduction to the SKM300GA123D

A Robust Foundation for High-Power Industrial Electronics

The Semikron SKM300GA123D is a SEMITRANS 2 IGBT module engineered for robust thermal performance and simplified system assembly in demanding high-power applications. With core specifications of 1200V | 300A | VCE(sat) 2.1V (typ), this module provides a reliable building block for industrial power conversion. Its key benefits include superior thermal transfer and streamlined mechanical integration, directly addressing the need for durable and efficient power stages in modern motor drives. For industrial motor drives up to 150 kW requiring a straightforward and dependable thermal design, the SKM300GA123D's isolated baseplate offers a distinct advantage.

Key Parameter Overview

A Data-Centric Look at Thermal and Electrical Characteristics

The specifications of the SKM300GA123D are tailored for efficiency and resilience in high-stress electrical environments. The parameters below highlight its capacity for robust performance, focusing on the critical values that engineers consider when designing for reliability and optimal power conversion.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | Tj = 25 °C | 1200 V |

| Continuous Collector Current | IC | Tc = 80 °C | 220 A |

| Repetitive Peak Collector Current | ICRM | tp = 1 ms | 400 A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 300 A, VGE = 15 V, Tj = 25 °C | 3.0 V (typ.) |

| Gate-Emitter Threshold Voltage | VGE(th) | IC = 8 mA, VGE = VCE | 5.5 V (typ.) |

| Thermal Resistance, Junction-to-Case | Rth(j-c) | per IGBT | 0.075 K/W |

| Thermal Resistance, Junction-to-Case | Rth(j-c)D | per Inverse Diode | 0.13 K/W |

| Isolation Voltage | Visol | AC, 1 minute | 2500 V |

Download the SKM300GA123D datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Power Conversion

The SKM300GA123D is optimally designed for high-power switching circuits where thermal management and long-term reliability are paramount. Its single-switch topology makes it a versatile component for applications such as DC choppers, boost converters, and the brake chopper circuits within larger systems.

A primary engineering challenge in designing a high-power Variable Frequency Drive (VFD) is managing the heat dissipated by the power semiconductors. The SKM300GA123D's integrated isolated copper baseplate directly addresses this. This design eliminates the need for a separate, often fragile, insulating layer between the module and the heatsink. This simplification reduces the number of components, minimizes assembly steps, and, most importantly, creates a more consistent and lower-resistance thermal path. By improving the efficiency of heat transfer, designers can potentially use a smaller heatsink or run the system at a higher power output without exceeding the maximum junction temperature, directly impacting system cost and power density. What is the primary benefit of its construction? Simplified thermal design and enhanced assembly reliability.

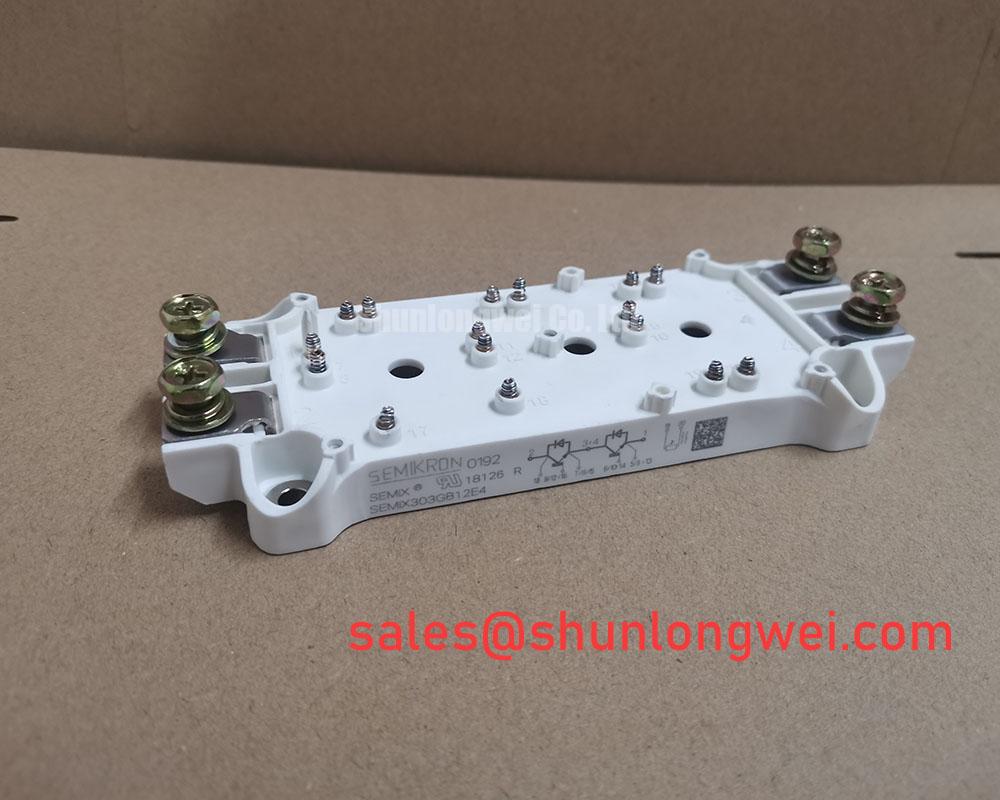

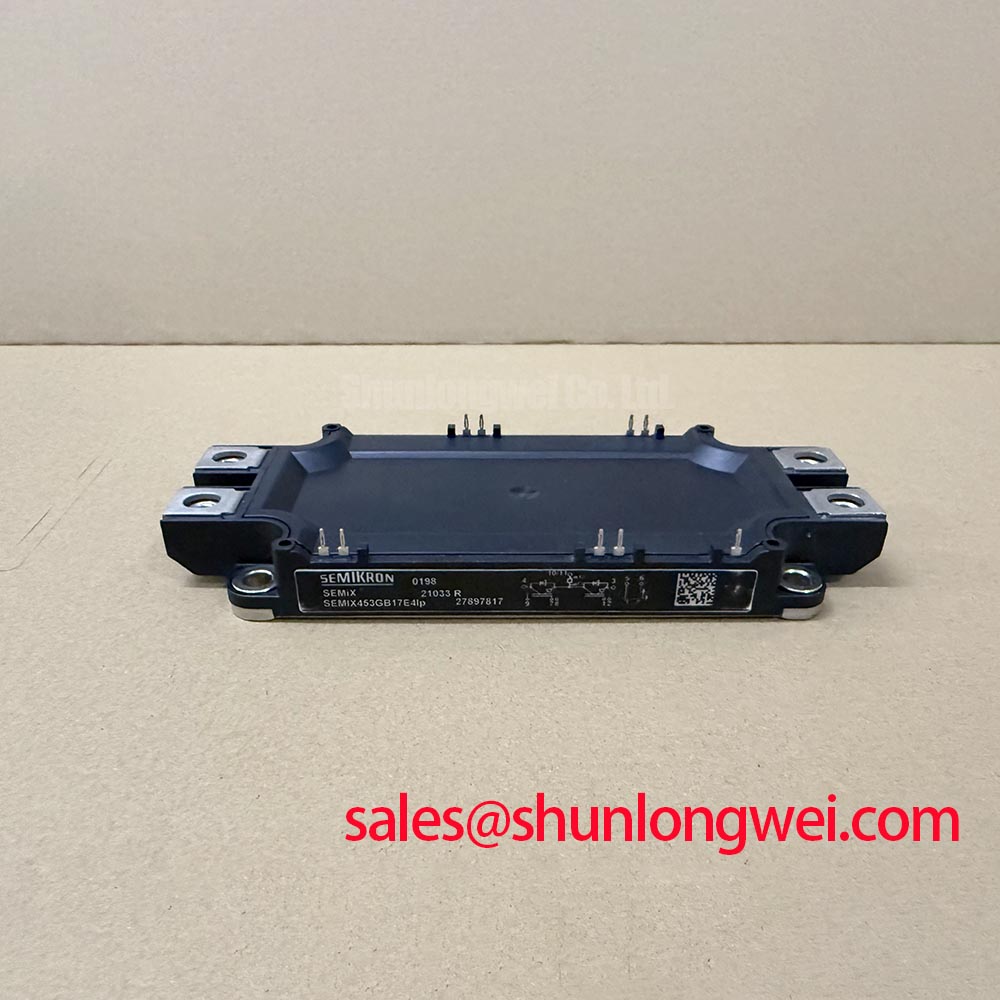

For systems that require higher power handling, the related SKM400GB123D offers increased current capacity within a similar package family, while the SKM200GB128D provides a solution for applications with lower current demands.

Technical Deep Dive

Inside the SEMITRANS® 2: An Analysis of its Construction and Reliability Features

The reliability of a power module is not just a function of the silicon chip but is heavily influenced by its packaging. The SKM300GA123D is housed in the industry-proven SEMITRANS 2 package, which features an isolated copper baseplate utilizing Direct Copper Bonding (DCB) technology. This construction offers several engineering advantages over non-isolated modules. The primary benefit is the elimination of external thermal insulation pads, which can be prone to inconsistencies and degradation over time. This leads to a more predictable and robust thermal interface.

A critical parameter for thermal design is the thermal resistance from junction to case, or Rth(j-c). For the SKM300GA123D, this value is an impressively low 0.075 K/W. This can be understood using an analogy: think of Rth(j-c) as the narrowness of a pipe designed to drain heat away from the silicon chip. A lower number signifies a wider, less restrictive pipe, allowing heat to be evacuated more efficiently to the heatsink. This efficiency is crucial for preventing the IGBT from overheating under heavy loads, a key factor in ensuring the long operational life of a power conversion system.

Industry Insights & Strategic Advantage

Meeting the Demands for Higher Efficiency and Durability in Industrial Automation

In the context of industrial automation and renewable energy, system uptime and total cost of ownership (TCO) are major drivers of component selection. The SKM300GA123D's design directly supports these objectives. Its robust construction, featuring an isolated baseplate and fast, soft inverse CAL (Controlled Axial Lifetime) diodes, contributes to higher system reliability and fewer field failures. The CAL diode technology is specifically engineered to have soft recovery characteristics, which reduces voltage overshoots and electromagnetic interference (EMI), simplifying the design of snubber circuits and helping the overall system meet stringent standards like IEC 61800-5-1.

Furthermore, the module's low collector-emitter saturation voltage (VCE(sat)) is a direct contributor to operational efficiency. VCE(sat) can be thought of as the "voltage toll" the current pays to pass through the IGBT when it is switched on. A lower toll means less energy is wasted as heat. This reduction in conduction losses not only improves the overall energy efficiency of the end application, such as a solar inverter or an industrial motor, but also lessens the burden on the cooling system, further reinforcing the design's thermal integrity and contributing to a lower TCO.

Frequently Asked Questions

Engineering Inquiries on Performance and Integration

What is the primary engineering advantage of the SKM300GA123D's isolated copper baseplate?

Its main advantage is the simplification of the thermal and mechanical assembly. By providing built-in electrical isolation, it eliminates the need for external insulating materials, which reduces assembly complexity, lowers the overall thermal resistance, and improves the long-term reliability of the thermal interface between the module and the heatsink.

How does the VCE(sat) of 3.0V (typ. at 300A, 25°C) impact the thermal design for a high-current application?

A lower VCE(sat) translates directly to lower conduction power loss (Power Loss = VCE(sat) x IC). This means less heat is generated within the IGBT chip for a given current. For a thermal designer, this reduced heat load provides more operating margin, potentially allowing for a more compact heatsink design or enabling higher current operation under challenging ambient conditions. For a deep dive into this topic, see our guide on unlocking IGBT thermal performance.

The datasheet mentions a "fast & soft inverse CAL diode." What does this mean for the module's performance?

CAL (Controlled Axial Lifetime) is a Semikron technology for freewheeling diodes. "Fast" refers to its ability to turn off quickly, which is essential for reducing switching losses in high-frequency applications. "Soft" refers to its recovery characteristic, meaning it turns off smoothly without causing large voltage spikes and oscillations. This reduces EMI and improves the reliability of the entire power circuit.

Is this module suitable for parallel operation to achieve higher current ratings?

While paralleling IGBT modules is a common technique, it requires careful design considerations. The SKM300GA123D features a positive temperature coefficient for its VCE(sat), which is beneficial for thermal stability and helps to balance current sharing between parallel modules. However, designers must ensure symmetrical busbar layout and use individual gate resistors to prevent oscillations and ensure proper dynamic current sharing. Consulting the manufacturer's application notes on paralleling is highly recommended.

Strategic Design Considerations

Aligning Component Selection with Long-Term System Goals

Selecting the SKM300GA123D is a strategic decision that prioritizes thermal robustness and manufacturing efficiency. Its design, centered around the isolated SEMITRANS 2 package, offers a clear path to simplifying system mechanics and enhancing thermal predictability. For engineering teams developing high-power industrial equipment, this module provides a solid foundation built for longevity and performance, aligning with long-term objectives of reducing system complexity and improving field reliability.