Content last revised on November 21, 2025

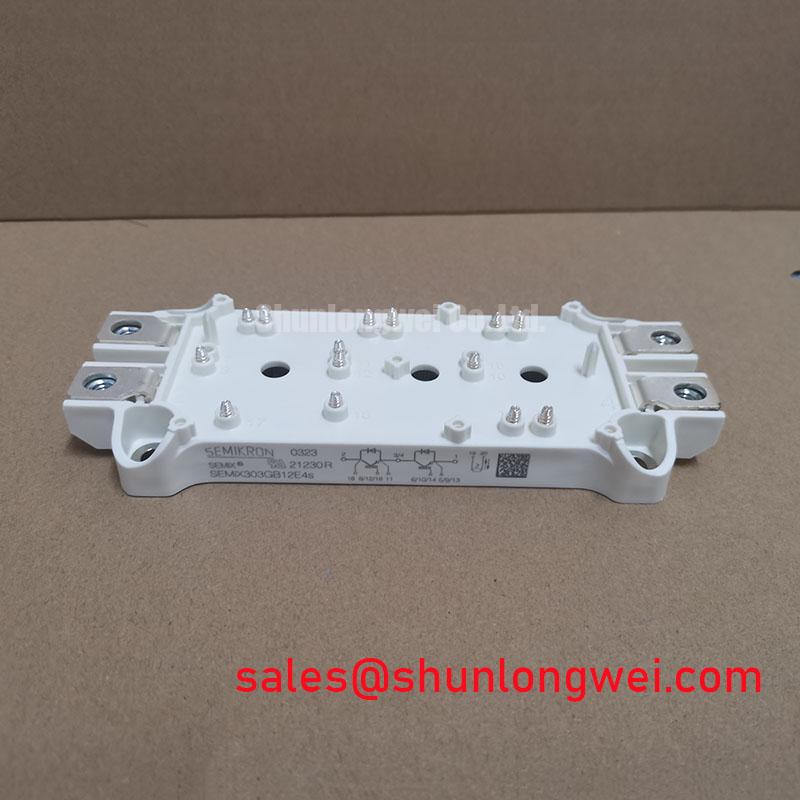

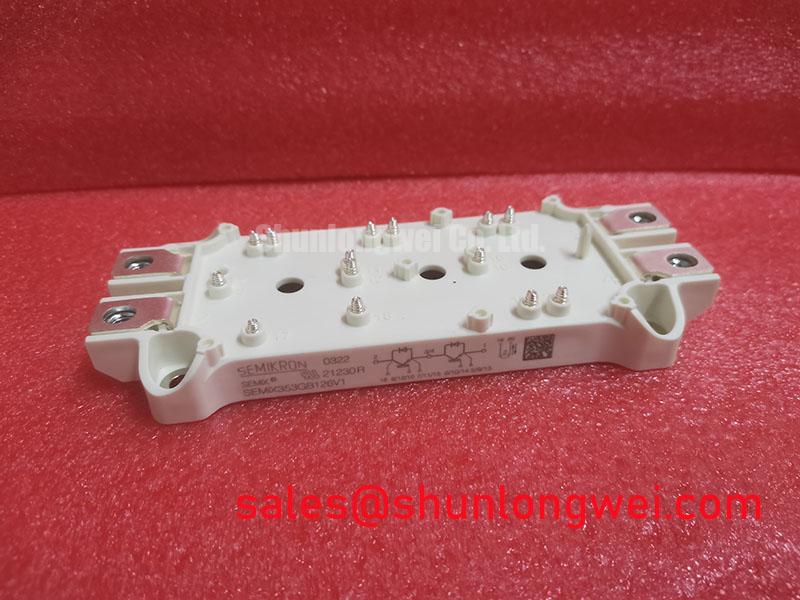

SEMIX303GB12E4S | 1200V 300A IGBT for Reliable Power Inverters

M2. Introduction & Key Highlights

The Semikron SEMIX303GB12E4S is a half-bridge IGBT module that leverages a solder-free spring contact design and advanced Trenchgate technology to deliver exceptional long-term reliability and simplified thermal management for high-power inverter systems. With top specifications of 1200V, a nominal collector current of 300A (410A max), and a low VCE(sat) of 1.7V, this module provides two critical engineering benefits: enhanced operational lifetime and simplified system assembly. What is the primary benefit of its pressure-contact design? It delivers outstanding resilience against thermal cycling fatigue by eliminating solder joints, a common point of failure. For high-reliability motor drives and UPS systems, the SEMIX303GB12E4S's solder-free design offers a decisive advantage in managing power cycling stress.

B2. Application Scenarios & Value

System-Level Reliability in Demanding Drive and UPS Applications

The SEMIX303GB12E4S is engineered for high-stakes applications where uptime and longevity are paramount. Its design directly addresses the core challenges found in industrial AC inverter drives, Uninterruptible Power Supplies (UPS), and high-power electronic welding systems.

Consider a variable frequency drive (VFD) controlling a conveyor system in a logistics hub. This system undergoes frequent start, stop, and load change cycles, subjecting its power electronics to constant thermal stress. This repeated expansion and contraction can lead to fatigue and cracking in conventional soldered modules, resulting in premature failure and costly downtime. The SEMIX303GB12E4S masterfully mitigates this risk. Its spring-contact interface provides a flexible, reliable connection that is inherently immune to solder fatigue, significantly extending the operational lifetime of the drive. This makes it an ideal component for systems requiring high Power Cycling Capability.

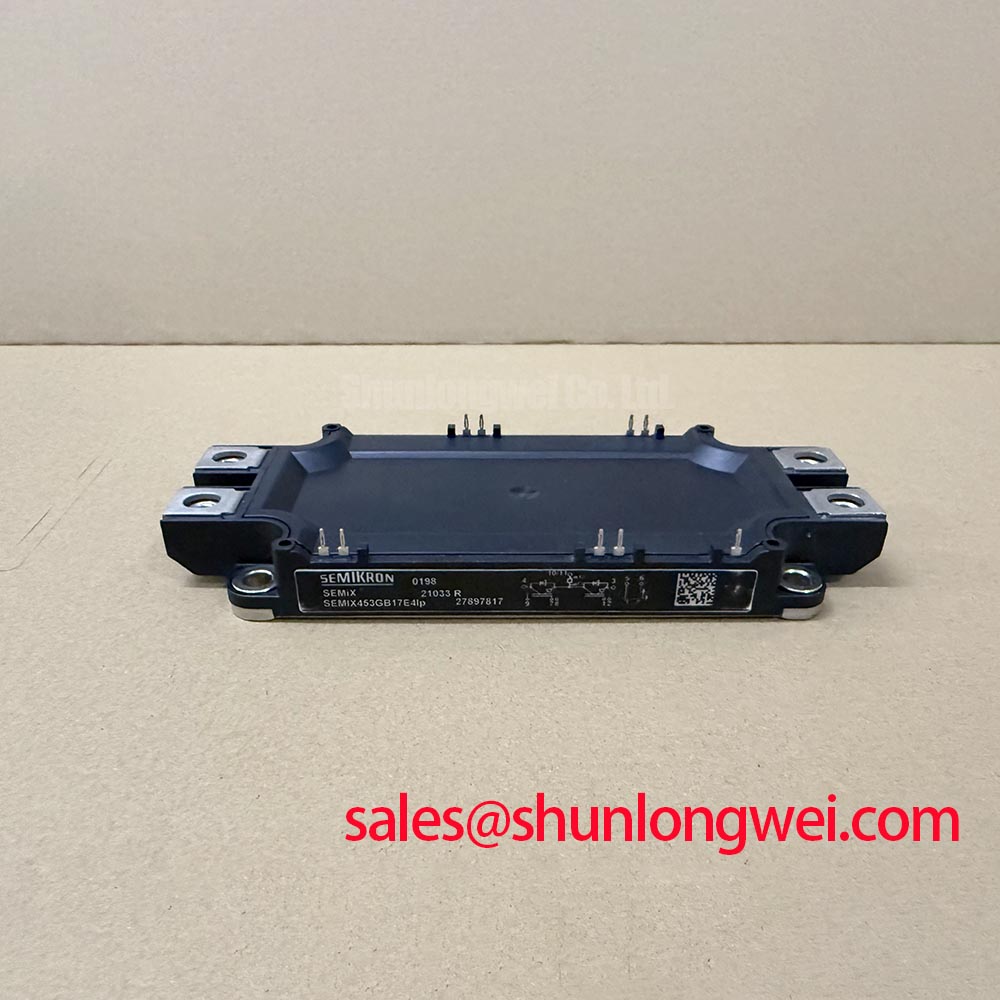

While this model is optimized for robust 300A applications, for systems requiring even greater power throughput within a similar footprint, the related SEMIX453GB12E4S offers a higher current rating in the same package family.

B3. Key Parameter Overview

A Specification Breakdown Focused on Efficiency and Robustness

The performance of the SEMIX303GB12E4S is defined by key electrical and thermal characteristics that directly influence system efficiency and durability. The parameters below have been selected from the official datasheet to aid in engineering evaluation.

| Parameter | Value | Conditions |

| Collector-Emitter Voltage (Vces) | 1200 V | Tj = 25 °C |

| Continuous Collector Current (Ic,nom) | 300 A | Tc = 80 °C |

| Maximum Collector Current (Ic) | 410 A | Tc = 25 °C |

| Collector-Emitter Saturation Voltage (VCE(sat)) | 1.7 V (typ.) / 2.15 V (max) | IC = 300 A, Tj = 25 °C |

| Short Circuit Withstand Time (tsc) | 10 µs | VCC = 800 V, VGE ≤ 15 V, Tj = 150 °C |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.085 K/W (per IGBT) |

Download the SEMIX303GB12E4S datasheet for detailed specifications and performance curves.

B1. Technical Deep Dive

Unpacking the Solder-Free Spring Contact and Trenchgate Design

Two core design choices distinguish the SEMIX303GB12E4S: its mechanical interface and its silicon technology. The SEMiX 3s housing utilizes spring contacts for all electrical connections, a fundamental departure from traditional solder-in modules. This solder-free approach is a strategic decision for improving long-term operational life. Think of the spring contact as a suspension system for the electrical connection, constantly adapting to the micro-expansions and contractions of materials during heat-up and cool-down. A rigid solder joint, by contrast, is like a solid bridge that can develop micro-cracks under the same repetitive stress, eventually leading to failure. This is one of the key benefits of spring contact IGBT module design.

On the silicon level, the module incorporates 4th generation Trenchgate IGBTs. This technology creates a vertical gate structure within the silicon, which optimizes the electric field distribution. If the collector-emitter saturation voltage (VCE(sat)) is the 'toll' that current pays to pass through the switch, Trenchgate technology effectively lowers that toll. This results in a typical VCE(sat) of just 1.7V at its nominal current, directly reducing conduction losses, increasing overall inverter efficiency, and simplifying the requirements for thermal management.

B5. Industry Insights & Strategic Advantage

Aligning with Industry Demands for Total Cost of Ownership and Uptime

In sectors like industrial automation and critical power infrastructure, the focus has shifted from initial component cost to the Total Cost of Ownership (TCO). Unplanned downtime is a significant financial drain, and the reliability of power conversion systems is a cornerstone of operational continuity. The SEMIX303GB12E4S directly supports this strategic priority. Its enhanced reliability, born from the solder-free design, translates into longer service intervals and a lower probability of failure in critical systems like Motor Drives and UPS.

Furthermore, the module's positive temperature coefficient for VCE(sat) is a critical feature for scalable system design. As the device heats up, its on-state resistance increases slightly, which naturally discourages excessive current hogging. This self-balancing behavior simplifies the process to parallel IGBT modules for higher power output, ensuring stable and reliable current sharing without complex, external balancing circuits. This synergy of efficiency and robustness makes the module a strategic asset for designing next-generation, high-availability power systems.

B7. FAQ

Engineering Questions on Performance and Integration

How does the positive temperature coefficient of VCE(sat) benefit designs using parallel modules?

A positive temperature coefficient is crucial for stable current sharing. If one module starts to carry more current and heats up, its VCE(sat) (on-state voltage drop) increases. This slightly higher 'resistance' naturally diverts current to the other, cooler modules, creating a self-balancing system that prevents thermal runaway in a single device. This feature, explained in resources from manufacturers like Infineon, is essential for building reliable high-current inverters by paralleling modules.

What is the engineering significance of the 10µs short-circuit withstand time?

The 10µs short-circuit rating provides a critical safety window for the system's protection circuitry to act. In the event of a fault, such as a motor winding short, the module can survive a direct short across the DC bus for 10 microseconds at a junction temperature of 150°C. This robustness allows the gate drive and control system time to detect the fault and safely shut down the IGBTs, preventing catastrophic module failure and protecting the rest of the system.

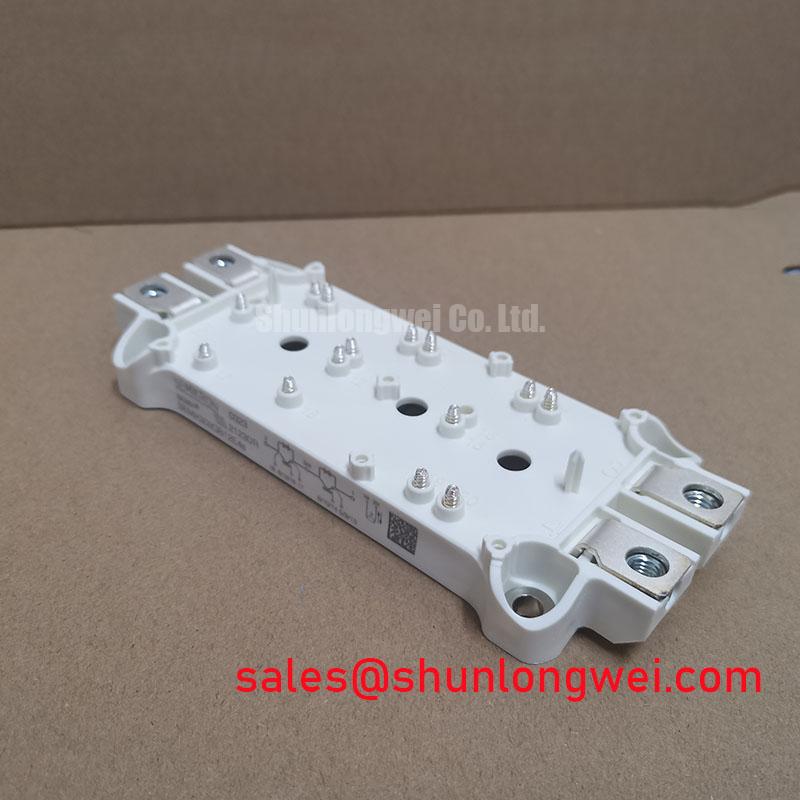

Is any special tooling required for mounting a SEMiX spring-contact module?

Mounting is simplified as it eliminates soldering, but it does require correct mechanical procedure. The module is typically pressed onto the driver board and heatsink using a defined pressure plate and screw-tightening sequence specified by the manufacturer, Semikron. This ensures that all spring contacts make a uniform, low-resistance connection to the PCB pads. While no soldering irons are needed, a torque wrench is essential to apply the correct and even mounting pressure.

A Strategic View on Component Selection

Opting for the SEMIX303GB12E4S is a decision that prioritizes long-term system value over initial component price. Its design intrinsically addresses the mechanical wear-out mechanisms that affect conventional power modules. For engineers and system architects developing power solutions for industrial automation, renewable energy, and critical power backup, this module represents a strategic investment in reliability, uptime, and a lower total cost of ownership over the product's entire lifecycle.