Content last revised on November 20, 2025

SKM200GB128D IGBT Module: Engineering Analysis for High-Efficiency Power Conversion

An In-Depth Look at the SEMITRANS 2 Half-Bridge Module

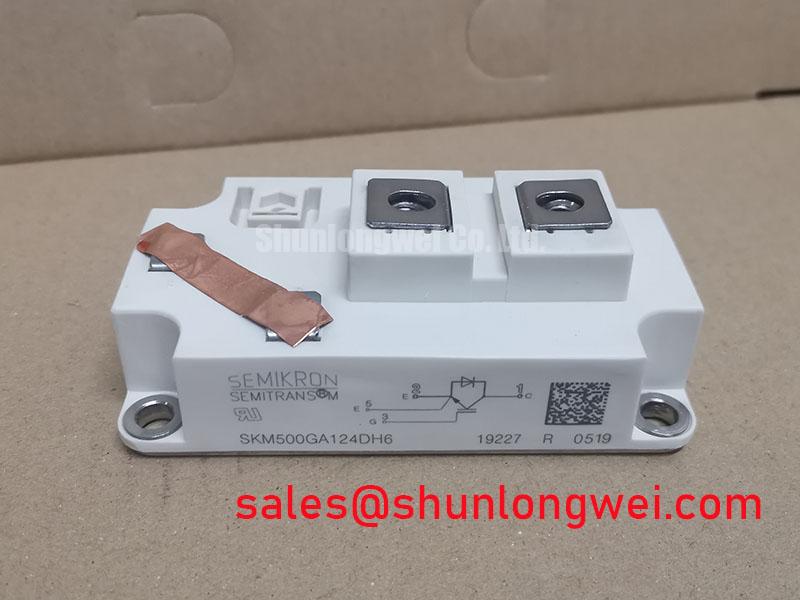

The SKM200GB128D is a high-reliability half-bridge IGBT module engineered for superior thermal performance and system robustness in demanding industrial applications, leveraging a low VCE(sat) and advanced CAL freewheeling diode technology. This SEMITRANS 2 module provides a robust foundation for power converters with key specifications of 1200V | 200A | VCE(sat) 2.5V (at 125°C). Its core benefits include a significantly reduced thermal load and enhanced switching reliability. For engineers designing high-frequency motor drives or power supplies, this module offers a dependable solution for managing both performance and long-term operational stability. With its excellent short-circuit withstand time, the SKM200GB128D is best suited for industrial drive systems where fault tolerance is a critical design requirement.

Application Scenarios & Value

System-Level Benefits in Industrial Motor Drives and Power Supplies

The SKM200GB128D is engineered to address core challenges in medium-power industrial applications. Its primary value is realized in systems like Variable Frequency Drives (VFDs), uninterruptible power supplies (UPS), and high-power switch-mode power supplies (SMPS). In a typical VFD application, the constant switching of the motor's inductive load generates significant thermal stress. The SKM200GB128D's low collector-emitter saturation voltage (VCE(sat)) of just 2.5V at a junction temperature of 125°C directly tackles this challenge. This low VCE(sat) minimizes conduction losses, which means less waste heat is generated for every amp of current delivered to the motor. The engineering outcome is a smaller, less expensive heatsink and potentially a more compact overall VFD enclosure, directly impacting system cost and power density.

Furthermore, the integrated CAL (Controlled Axial Lifetime) freewheeling diode exhibits soft recovery characteristics. This is critical for reducing voltage overshoots during IGBT turn-on, a common source of electromagnetic interference (EMI) and component stress. By mitigating these transients at the source, designers can simplify snubber circuits and EMI filtering, accelerating compliance with standards such as IEC 61800-3. While this module is optimized for 200A applications, for systems demanding higher current capacity within the same voltage class, the related SKM300GB128D offers a direct path for scaling power output.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the SKM200GB128D are tailored for performance and durability. The parameters listed below are critical for thermal modeling, gate drive design, and reliability assessment. Highlighting these values allows engineers to quickly ascertain the module's fit within their system architecture.

| Parameter | Symbol | Condition | Value |

|---|---|---|---|

| Collector-Emitter Voltage | Vces | Tj = 25 °C | 1200 V |

| Continuous DC Collector Current | Ic | Tc = 25 °C / 80 °C | 290 A / 200 A |

| Collector-Emitter Saturation Voltage | VCE(sat) | Ic = 200 A, Tj = 125 °C | Typ. 2.5 V |

| Short Circuit Withstand Time | tsc | Vcc = 800 V, Tj = 125 °C | 10 µs |

| Thermal Resistance, Junction to Case | Rth(j-c) | Per IGBT | 0.16 K/W |

| Isolation Voltage | Visol | AC, 1 minute | 2500 V |

Download the SKM200GB128D datasheet for detailed specifications and performance curves.

Technical Deep Dive

Engineering Impact of the CAL Freewheeling Diode

A standout feature of the SKM200GB128D is its use of a CAL (Controlled Axial Lifetime) freewheeling diode. This is not simply a standard diode; it's a piece of silicon technology specifically engineered for soft recovery. What is the primary benefit of its soft recovery? It significantly reduces voltage overshoots and high-frequency oscillations. Think of it like a vehicle's suspension system. A stiff, basic suspension transfers every bump in the road directly to the chassis, causing a jarring ride. A well-engineered suspension, however, absorbs the impact smoothly. The CAL diode acts like the advanced suspension, "smoothing" the electrical behavior as the current rapidly commutates from the diode to the IGBT. This softness directly lowers the turn-on switching losses in the IGBT and dramatically reduces radiated and conducted EMI, helping systems achieve EMC compliance with less external filtering.

Frequently Asked Questions (FAQ)

How does the low VCE(sat) of 2.5V at 125°C benefit my design?

This parameter is a direct measure of the module's efficiency during conduction. A lower VCE(sat) means lower power loss in the form of heat. This allows for the use of a smaller thermal management system, saving space, weight, and cost, while also improving the overall reliability by operating at a lower junction temperature.

What is the practical advantage of the 10 µs short-circuit withstand time?

This specification provides a critical safety buffer. In the event of a catastrophic load short-circuit, the module can survive for 10 microseconds before failing. This window is crucial for the system's protection circuitry (e.g., the gate driver with desaturation detection) to sense the fault and safely shut down the IGBT, preventing module destruction and protecting downstream equipment.

What does the "CAL" diode designation signify for system reliability?

"CAL" stands for Controlled Axial Lifetime, a Semikron-Danfoss technology that creates a freewheeling diode with "soft" recovery characteristics. This reduces destructive voltage spikes and ringing during switching, which not only improves EMI performance but also lowers stress on the IGBT and surrounding components, contributing to a longer operational lifetime for the entire power converter.

Is the SEMITRANS 2 package suitable for high-vibration industrial environments?

Yes, the SEMITRANS 2 housing is an industry-standard package known for its mechanical robustness. It features an isolated baseplate and screw terminals, ensuring secure electrical and mechanical connections that are well-suited for demanding applications like industrial motor drives, conveyor systems, and welding power supplies where vibration and mechanical stress are common.

Strategic Design Implications

Integrating the SKM200GB128D into a power system is a strategic decision that prioritizes long-term reliability and efficiency over minimal upfront component cost. The combination of low conduction losses, robust short-circuit tolerance, and controlled switching behavior provided by the CAL diode offers a compelling engineering advantage. It enables designers to build more compact, efficient, and durable power converters that meet increasingly stringent industry standards for performance and operational uptime.