Content last revised on January 29, 2026

VUB145-16NO1: High-Reliability Three-Phase Rectifier Bridge with Integrated Brake Chopper

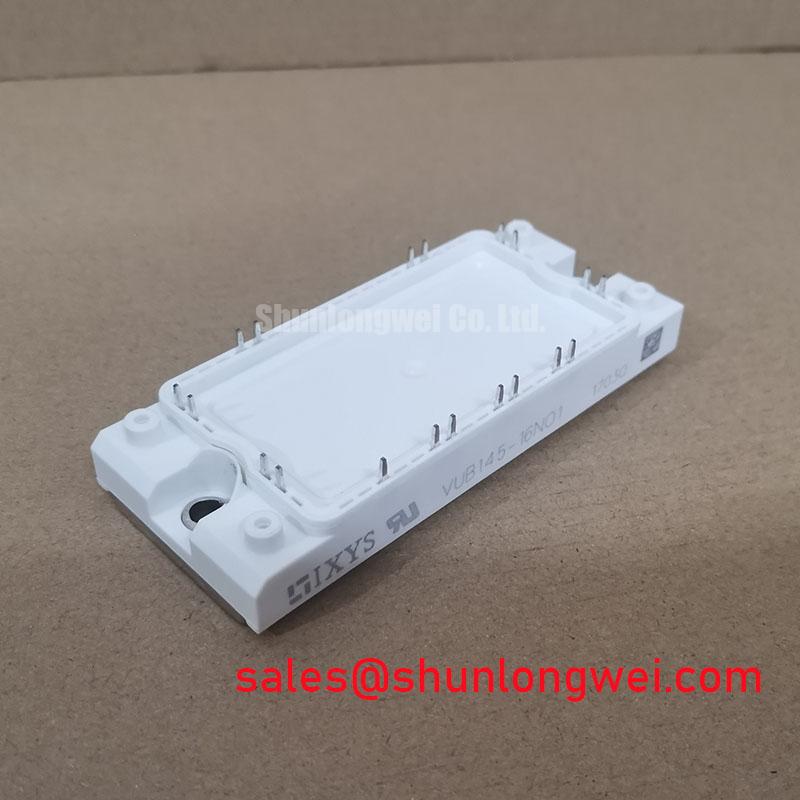

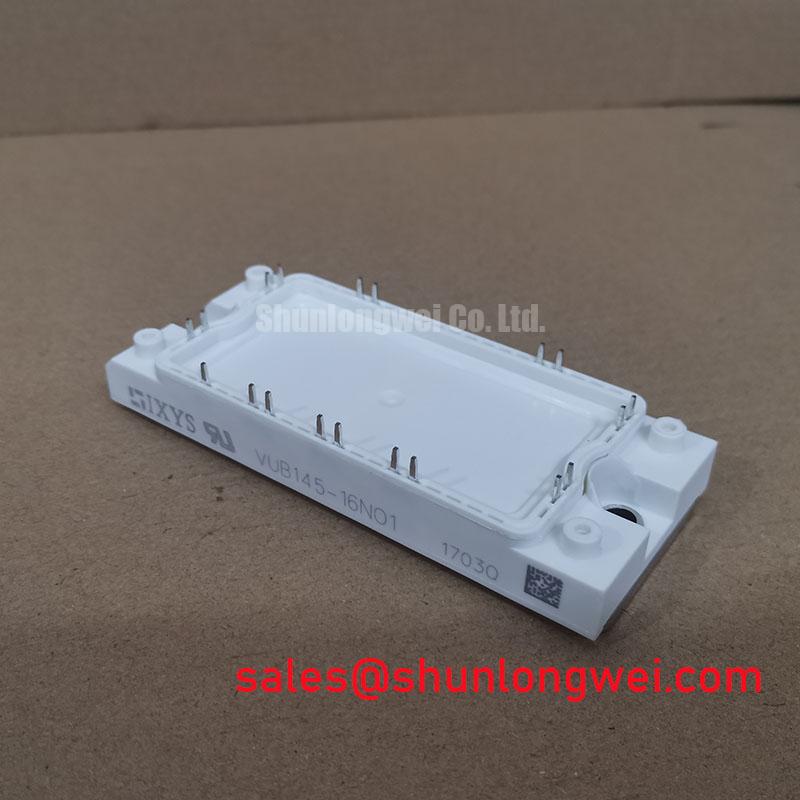

Introduction to the VUB145-16NO1 Power Module

The IXYS VUB145-16NO1 is an integrated power module engineered for high-reliability AC-DC power conversion, combining a three-phase rectifier bridge with a brake chopper IGBT and a fast recovery diode. This module delivers a robust solution for motor drives and power supply applications, featuring core specifications of 1600V rectifier blocking voltage, 145A forward current, and a 1200V IGBT for the braking circuit. Key engineering benefits include simplified system assembly and enhanced thermal efficiency due to its integrated design. It directly addresses the need for compact and reliable power stages in modern variable frequency drives. For applications requiring different current or voltage ratings, the related VUB72-16NO1 provides an alternative within the same product family.

Application Scenarios & Value

System-Level Benefits in AC Motor Drive Integration

The VUB145-16NO1 is purpose-built for the input stage of AC motor drives, uninterruptible power supplies (UPS), and other switched-mode power supplies. A primary engineering challenge in these systems is managing both the main power rectification and the regenerative energy from the motor during deceleration. This module provides a best-fit solution by co-packaging the six-diode rectifier bridge for converting three-phase AC input to a DC bus, and an IGBT with an anti-parallel freewheeling diode (FWD) to manage braking energy. This integration significantly reduces component count, simplifies PCB layout and assembly, and minimizes parasitic inductance compared to a discrete solution. The result is a more compact, reliable, and cost-effective power conversion stage, crucial for competitive Variable Frequency Drive (VFD) and servo drive designs.

Key Parameter Overview

Decoding Specs for Integrated Power Conversion

The technical specifications of the VUB145-16NO1 are tailored for robust industrial power applications. The parameters below highlight its capacity to handle demanding electrical and thermal loads within a single, convenient package.

| Parameter | Value | Engineering Significance |

|---|---|---|

| VRRM (Rectifier Diode) | 1600 V | Provides a substantial safety margin for operation on 400V, 480V, and even 575V three-phase AC lines, ensuring high reliability against voltage transients. |

| IdAVM (Average Forward Current) | 145 A (TC = 80°C) | Indicates a high current handling capability, suitable for powering motors and systems in the 45-75 kW range, depending on cooling efficiency. |

| VCES (Brake IGBT) | 1200 V | The IGBT's voltage rating is well-matched to typical DC bus voltages found in 400V/480V AC drive systems, ensuring robust performance during dynamic or regenerative braking events. |

| IC25 (Brake IGBT) | 141 A (TC = 25°C) | Defines the nominal current capacity of the brake chopper, allowing for rapid dissipation of regenerative energy into a braking resistor. |

| Package | E2 Package | An industry-standard, low-profile package with screw terminals that simplifies mechanical mounting to a heatsink and ensures reliable electrical connections. |

Download the VUB145-16NO1 datasheet for detailed specifications and performance curves.

Frequently Asked Questions (FAQ)

What is the primary benefit of integrating the rectifier and brake chopper in the VUB145-16NO1?

The main advantage is system simplification. By combining these two functions into a single module, engineers can reduce assembly time, lower component count, minimize connection inductance, and improve overall thermal management, leading to a more compact and reliable final product.

How does the 1600V rating of the rectifier diodes benefit a 480V AC system?

A 480V AC line produces a peak voltage of approximately 679V, and the DC bus voltage is typically around 1.4 times the AC RMS voltage. The 1600V rating provides a significant safety margin (over 2x) against line surges and transients, which is critical for ensuring long-term reliability in harsh industrial environments.

Is the brake chopper IGBT in this module designed for continuous operation?

No, the brake chopper is designed for intermittent duty, managing the regenerative energy generated during motor deceleration. Its thermal and electrical ratings are specified for dynamic braking cycles, not for continuous power dissipation. System design must ensure the external braking resistor and control strategy adhere to these operational limits.

What does the "fast recovery diode" paired with the brake IGBT do?

The fast recovery freewheeling diode (FWD) provides a path for the current when the IGBT turns off. Its "fast recovery" characteristic is crucial for minimizing switching losses and protecting the IGBT from voltage spikes during the high-frequency switching common in braking applications. What is the benefit of its fast recovery diode? It enables efficient high-frequency switching in the brake circuit.

Strategic Advantage

A Forward-Looking Perspective on Power Module Integration

The VUB145-16NO1 exemplifies a critical trend in power electronics: functional integration to boost power density and reliability. As industrial automation and energy efficiency standards become more stringent, designers are under pressure to create smaller, more robust motor drives and power converters. Modules like this provide a strategic advantage by offering a pre-validated, optimized subsystem. This approach allows engineering teams to focus on higher-level system design and control software, rather than the complexities of discrete power stage layout and thermal management. By leveraging the integrated rectifier and brake chopper, manufacturers can accelerate their time-to-market and deliver more competitive solutions for a wide array of industrial applications.