Content last revised on January 9, 2026

Mitsubishi CM100DY-24NF IGBT Module | Mastering Efficiency in 1200V Power Conversion

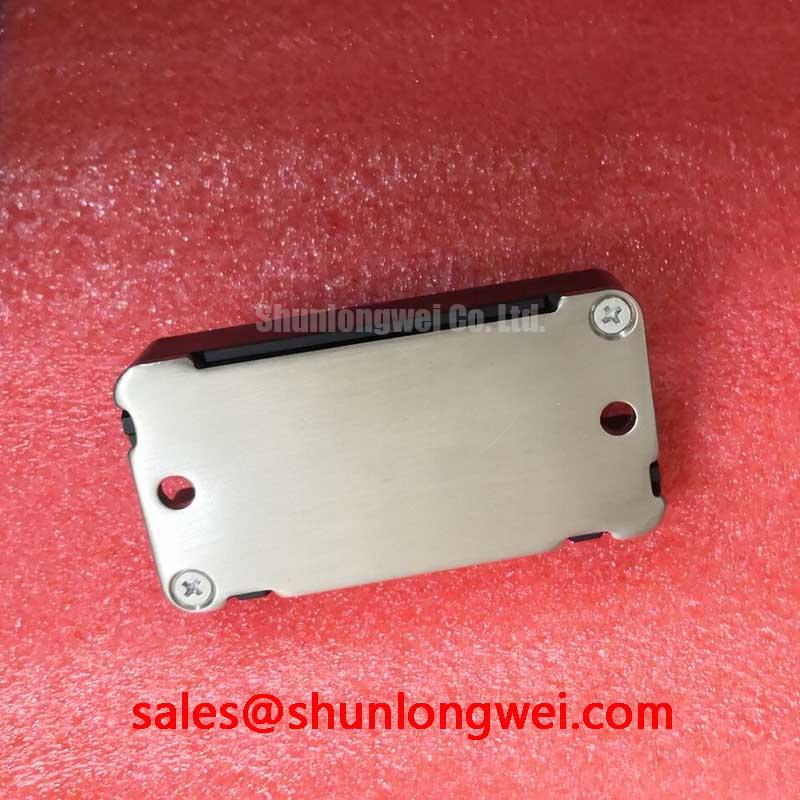

The Mitsubishi CM100DY-24NF is a high-performance dual IGBT module engineered for demanding power conversion systems. As a 1200V, 100A half-bridge module from the renowned NF-Series, it delivers an optimal balance of low power loss, robust reliability, and superior switching characteristics. This module is not just a component; it's a foundational building block for creating highly efficient and durable motor drives, uninterruptible power supplies (UPS), and industrial automation systems.

A Closer Look at the Technology: 6th Generation CSTBT™ and Optimized Diodes

The performance of the CM100DY-24NF is rooted in Mitsubishi's advanced semiconductor technology. Understanding these features reveals why it stands out in crowded power applications.

-

Carrier Stored Trench-gate Bipolar Transistor (CSTBT™)

Technical Principle: This module utilizes Mitsubishi's 6th generation CSTBT™ chip. Unlike standard trench-gate IGBTs, this technology incorporates a unique carrier stored layer beneath the trench gate. This structure significantly enhances conductivity modulation during the on-state.

Application Value: The direct result is a remarkably low collector-emitter saturation voltage (Vce(sat)). For system designers, this means drastically reduced conduction loss, leading to less heat generation. This allows for smaller, more cost-effective heatsinks and improves the overall energy efficiency of the end application, a critical factor in systems that operate continuously.

-

Soft & Fast Recovery Free-Wheeling Diode (FWD)

Technical Principle: Each IGBT is paired with a free-wheeling diode optimized for soft recovery characteristics. This ensures that the reverse recovery current drops off smoothly, rather than abruptly, minimizing voltage spikes and oscillations.

Application Value: This "soft" behavior significantly reduces electromagnetic interference (EMI). Engineers can simplify their snubber circuit designs and may reduce the size and cost of the required EMI filter, accelerating time-to-market and easing the path to EMC compliance.

Solving Real-World Challenges Across Applications

The technical advantages of the Mitsubishi CM100DY-24NF translate into tangible benefits in various high-stakes industrial environments.

- AC Motor Drives & Servo Control: In motor control, efficiency and precision are key. The low Vce(sat) reduces thermal stress on the drive, enhancing system longevity. The fast yet smooth switching enables higher control resolution, resulting in smoother motor operation and more precise positioning in servo applications. For more options, you can Explore More IGBT Modules suitable for your drive design.

- Uninterruptible Power Supplies (UPS): Reliability is non-negotiable in UPS systems. The inherent efficiency of the CM100DY-24NF minimizes energy waste in standby and active modes, lowering the total cost of ownership. Its robust thermal performance ensures the system can handle full load during a critical power outage without failing.

- Welding Equipment: Inverter-based welders subject components to intense current pulses. This module's robust construction and excellent thermal cycling capability allow it to withstand these demanding, repetitive load conditions, ensuring a stable welding arc and a long service life for the equipment.

Critical Technical Parameters at a Glance

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Collector Current (Ic) | 100 A |

| Collector-Emitter Saturation Voltage (Vce(sat)) (Typ. @ Ic=100A, Tj=125°C) | 1.9 V |

| Package Type | Standard 2-in-1 (Half-Bridge) |

| Isolation Voltage (Viso) | 2500 Vrms (1 minute) |

| Built-in Feature | NTC Thermistor for Temperature Monitoring |

Selection Guidance: CM100DY-24NF vs. Integrated CIB Modules

Engineers often weigh the benefits of a modular approach versus a highly integrated one. The Mitsubishi CM100DY-24NF is a dual (half-bridge) module, offering excellent design flexibility. It is the perfect choice for building single-phase H-bridge inverters or as one leg in a three-phase IGBT inverter configuration. This modularity is invaluable for custom power stage layouts or applications that don't require a standard rectifier and brake chopper.

In contrast, a Converter-Inverter-Brake (CIB) module integrates the three-phase input rectifier, the brake chopper, and the three-phase inverter into a single package. While CIBs can simplify assembly for standard motor drives, the CM100DY-24NF provides the freedom and performance necessary for specialized, high-efficiency designs.

Common Questions Answered

- How can I ensure optimal thermal management for this module?

Effective thermal management hinges on three things: using a high-quality thermal interface material (TIM) between the module baseplate and the heatsink, applying the correct mounting torque to ensure minimal thermal resistance, and actively using the built-in NTC thermistor to provide real-time temperature feedback to your controller for overload protection. - Is it possible to parallel these modules for higher current capacity?

Yes, paralleling is possible but requires careful engineering. To ensure balanced current sharing, it is critical to design a symmetrical PCB layout that equalizes stray inductances in the power path for each module. Additionally, using gate resistors with tight tolerances is essential for synchronized switching. For designs requiring higher power, it is advisable to Contact Us for a Quote and expert design support.