Content last revised on January 18, 2026

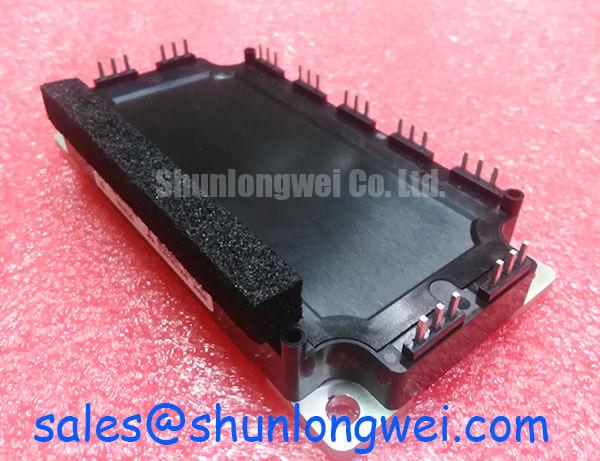

Mitsubishi CM100TJ-24F | A Workhorse 1200V/100A Six-Pack IGBT for Industrial Power Conversion

The Mitsubishi CM100TJ-24F is an industry-proven IGBT module engineered for reliability and efficiency in demanding medium-power applications. As a member of Mitsubishi's F-Series, this module integrates a full three-phase inverter bridge into a single, compact package, offering designers a robust solution for motor control, power supplies, and other switched-mode power conversion systems. Its core design philosophy balances low conduction losses with durable switching performance, making it a go-to component for systems requiring long-term operational stability.

Key Performance Characteristics

Engineers specifying power stages require precise data for thermal and electrical modeling. The CM100TJ-24F delivers a well-balanced profile suitable for a wide range of industrial frequency applications. For detailed specifications and application notes, you can download the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 1200V |

| Continuous Collector Current (IC) | 100A (Tc = 80°C) |

| Collector-Emitter Saturation Voltage (VCE(sat)) | 2.7V (Typ.) @ IC = 100A, Tj = 25°C |

| Configuration | Six-Pack (Three-Phase Bridge) |

| Maximum Junction Temperature (Tj max) | 150°C |

| Isolation Voltage (Viso) | 2500Vrms (1 min) |

Application Scenarios and Engineering Value

The true value of an IGBT module is realized in its target applications. The integrated and robust nature of the CM100TJ-24F provides distinct advantages across several key industrial sectors.

- Variable Frequency Drives (VFDs): In motor drives for systems up to 45kW, the six-pack topology of the CM100TJ-24F dramatically simplifies the power stage design. It minimizes stray inductance, reduces component count, and streamlines the assembly process compared to using discrete IGBTs, leading to a more reliable and compact inverter design.

- Uninterruptible Power Supplies (UPS): The module's high 1200V breakdown voltage provides a significant safety margin in mains-connected UPS systems. Its low VCE(sat) ensures high efficiency during normal operation, reducing cooling requirements and operational costs over the system's lifetime.

- Welding Power Supplies: Welding applications demand components that can withstand high pulse currents and thermal cycling. The robust thermal interface and proven silicon of the CM100TJ-24F provide the durability needed to manage the demanding load profiles inherent in advanced welding equipment.

Technical Deep Dive: The Trench Gate Advantage

At the heart of the CM100TJ-24F's performance is its use of Trench Gate Field Stop IGBT technology. Unlike older planar gate structures, the trench gate design creates a vertical channel for current flow. This architecture significantly increases the cell density of the silicon, which directly results in a lower on-state resistance and, consequently, a lower collector-emitter saturation voltage (VCE(sat)). For the design engineer, this fundamental technological advantage translates into lower conduction losses, which is the primary source of heat generation in low-to-medium frequency applications. This enhanced efficiency simplifies thermal management, potentially allowing for smaller heatsinks and a more compact overall system design.

Design and Selection Considerations

The CM100TJ-24F is an excellent choice for new designs and as a drop-in replacement in many existing systems due to its standard industrial package. Its electrical characteristics are well-suited for switching frequencies up to approximately 15 kHz. For applications requiring higher power output within a similar package footprint, designers might consider a module like the CM200DY-24H, which offers a 200A current rating. However, for systems in the 75-100A range, the CM100TJ-24F provides an optimal balance of cost, performance, and proven reliability. Understanding the nuances of IGBT datasheets is crucial for making the correct selection for your specific application's load profile and efficiency targets.

Frequently Asked Questions (FAQ)

- What are the recommended gate drive conditions for the CM100TJ-24F? For optimal performance and to prevent parasitic turn-on, a gate drive voltage of +15V for turn-on and a negative voltage between -5V and -10V for turn-off is recommended. This provides a robust noise margin against dV/dt induced switching.

- Is this module suitable for paralleling? While paralleling is technically possible, it requires careful circuit layout to ensure symmetrical current sharing, particularly through gate drive circuitry and power bus bars. For applications requiring more than 100A, it is often more reliable and cost-effective to select a single, higher-current rated IGBT module.

- How does the isolated baseplate benefit the design? The module features a baseplate that is electrically isolated from the power terminals. This allows multiple modules to be mounted on a single, non-isolated heatsink, simplifying mechanical assembly and improving the overall thermal efficiency of the power conversion unit.

For further design support or to discuss your specific power requirements, please contact our technical team to explore our full range of IGBT modules.