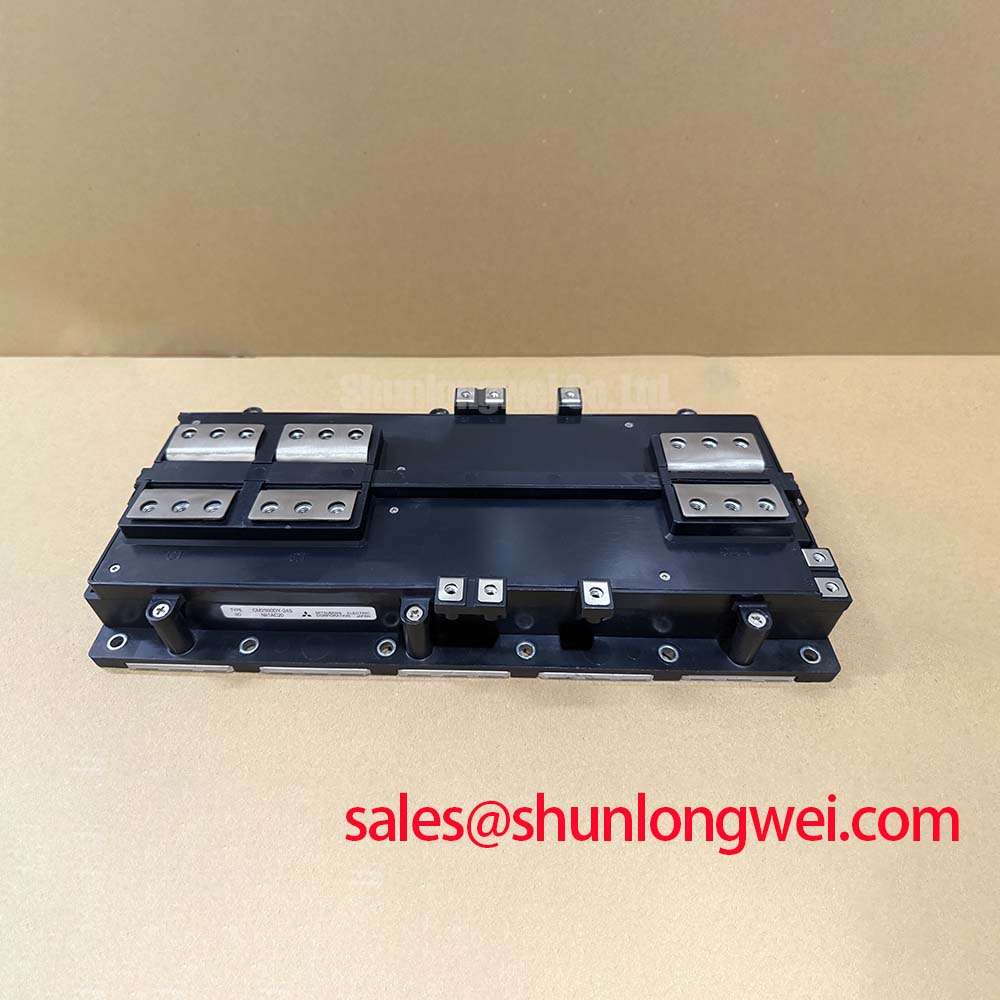

CM2500DY-24S | 1200V 2500A IGBT Module Datasheet Review

Engineered for extreme power density, the Mitsubishi CM2500DY-24S IGBT module delivers unparalleled thermal stability for high-reliability systems. With core specifications of 1200V | 2500A | Rth(j-c) 0.011°C/W, this device ensures minimal power loss and exceptional heat dissipation. Its primary benefits include superior operational longevity and robust short-circuit withstand capabilities. For engineers questioning how to manage thermal cycling in megawatt-scale converters, this module's low thermal impedance and high-integrity build provide a foundational solution for long-term reliability.

In the landscape of high-power electronics, particularly in applications like multi-megawatt wind turbines, large-scale motor drives, and grid infrastructure, the ability to manage immense electrical and thermal loads is fundamental. The Mitsubishi Electric CM2500DY-24S is a high-power switching module designed to address these challenges directly. This component integrates a single IGBT and a free-wheeling diode in a high-current package, providing a robust building block for inverters and converters where performance and dependability are critical operational parameters. Its architecture is specifically tailored to facilitate efficient heat extraction, a cornerstone of system longevity and consistent performance.

Engineered for Uptime: Where Thermal Stability is Paramount

The CM2500DY-24S is specified for systems where thermal management is a primary design constraint and operational uptime is directly linked to component robustness. Its high current capacity combined with low thermal resistance makes it a suitable candidate for demanding power conversion cycles.

- Industrial Motor Drives: In large-scale variable frequency drives (VFDs) for applications like mining excavators, steel rolling mills, and marine propulsion, the module's ability to handle 2500A enables precise control over high-power motors while its thermal efficiency prevents overheating during prolonged operation.

- Renewable Energy Inverters: For utility-scale solar and wind power inverters, converting DC to high-quality AC requires components that can withstand constant thermal cycling. The CM2500DY-24S's robust construction ensures reliable energy feed into the grid, maximizing generation uptime. For systems demanding high efficiency and reliability, understanding the core principles of IGBTs in wind-to-grid conversion is essential.

- Power Grid & FACTS: In applications such as Static VAR Compensators (SVC) or HVDC transmission systems, this IGBT module provides the high-current switching capability necessary for stabilizing the power grid and ensuring efficient power flow.

What is the primary benefit of its low Rth(j-c) value? It ensures a highly efficient thermal path, minimizing junction temperature rise under load. For systems where continuous operation at over 2000A is standard, the CM2500DY-24S's thermal impedance of 0.011°C/W makes it the optimal choice for ensuring long-term operational stability.

Comparative Insights for Informed Decisions

When evaluating high-power IGBT modules, design engineers must assess key parameters to ensure the selected component aligns with system requirements. The following table provides a factual comparison based on publicly available datasheet information to support this decision-making process. This is not a recommendation but a data-centric overview to empower your design analysis. For a deeper understanding of how different manufacturers approach module design, resources like the IGBT Showdown: Semikron vs. Infineon can provide valuable context.

| Parameter | Mitsubishi CM2500DY-24S | Alternative High-Power Module (Typical) | Engineering Consideration |

|---|---|---|---|

| Collector Emitter Voltage (Vces) | 1200V | 1200V / 1700V | Ensures sufficient voltage blocking capability for standard industrial bus voltages with safety margin. |

| Continuous Collector Current (Ic) @ Tc=80°C | 2500A | 2000A - 2400A | A higher continuous current rating allows for greater power throughput or increased thermal headroom in a given design. |

| Collector-Emitter Saturation Voltage (Vce(sat)) typ. @ Ic | 1.80V @ 2500A | 1.9V - 2.2V | Lower Vce(sat) directly translates to lower conduction losses, reducing the overall heat generated by the module and improving system efficiency. |

| Thermal Resistance, Junction to Case (Rth(j-c)) per IGBT | 0.011 °C/W | 0.012 - 0.015 °C/W | This critical parameter indicates how effectively heat is transferred from the semiconductor junction to the module's baseplate. A lower value signifies superior thermal performance. |

Key Technical Specifications at a Glance

The performance of the CM2500DY-24S is defined by its electrical and thermal characteristics. The following parameters are crucial for system design, simulation, and validation. For a comprehensive list of specifications, please download the official datasheet.

| Parameter | Value | Engineering Significance |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 1200V | Provides the necessary voltage rating for applications on 480V to 690V AC lines, offering a robust safety margin against transient overvoltages. |

| Collector Current (DC) (Ic) | 2500A (Tc = 80°C) | This high current rating is a primary feature, enabling the module to be used in power conversion systems well into the megawatt class. |

| Collector-Emitter Saturation Voltage (Vce(sat)) | 1.80V (typ) / 2.40V (max) at 2500A | Indicates the voltage drop across the IGBT when fully on. The low typical value minimizes conduction losses, directly impacting overall system efficiency and reducing cooling requirements. |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) | 0.011 °C/W (IGBT), 0.022 °C/W (Diode) | This parameter is analogous to the narrowness of a pipeline for heat flow. The extremely low value for the IGBT signifies a highly efficient path for heat to escape from the silicon chip to the heatsink, crucial for reliability at 2500A. |

| Short-Circuit Withstand Time (tsc) | 10µs (at Vcc=600V, Vge=15V, Tj=125°C) | Defines the module's ability to survive a catastrophic short-circuit event, allowing protective circuitry time to react and prevent failure. This is a key indicator of device ruggedness. |

Strategic Advantages in Power Conversion

Integrating a module like the CM2500DY-24S offers a distinct strategic edge in the development of next-generation power systems. As industries push towards higher efficiency and greater power density, the reliance on components with superior thermal performance intensifies. The low Vce(sat) of this device, a hallmark of Mitsubishi's advanced IGBT chip technology, directly supports initiatives aimed at reducing operational energy costs and meeting stringent efficiency standards. Furthermore, its robust thermal design allows for more compact system layouts or operation in more demanding ambient conditions, providing greater design flexibility and potentially lowering the total cost of ownership through simplified cooling system requirements.

Deployment Spotlight: Upgrading a 1.5MW Wind Turbine Inverter

Consider a scenario where an existing 1.5MW wind turbine inverter experiences frequent thermal trips during peak summer generation, limiting its annual energy production. A retrofit using CM2500DY-24S modules could resolve this bottleneck. The module's higher current rating (2500A) provides significant operational margin compared to older 2000A or 2200A components. More critically, its lower thermal resistance (Rth(j-c)) means that for the same amount of dissipated power, the internal chip temperature remains lower. This enhanced thermal efficiency allows the inverter to operate reliably at full capacity even on the hottest days, boosting energy output and improving the operator's return on investment without requiring a costly overhaul of the entire cooling infrastructure.

A Deeper Look into Thermal Architecture

The exceptional thermal performance of the CM2500DY-24S is not accidental; it is the result of deliberate design choices in its construction. The module utilizes an AlN (Aluminum Nitride) ceramic isolation layer. Why is an AlN substrate critical for high-power modules? It offers significantly higher thermal conductivity compared to conventional Al2O3 (Alumina), creating a more effective bridge for heat to travel from the IGBT chip to the copper baseplate. This superior material choice is fundamental to achieving the device's low Rth(j-c) value. This focus on the thermal path ensures that the heat generated during high-current switching and conduction phases is efficiently removed, keeping the junction temperature within safe operating limits and drastically improving the module's power cycling capability and overall lifespan.

Technical FAQ

1. What is the significance of the 2.4V maximum Vce(sat) rating for the CM2500DY-24S?The maximum Vce(sat) of 2.4V at 2500A and Tj=125°C is a critical worst-case parameter for thermal design. Engineers must use this value, not the typical 1.80V, to calculate the maximum possible conduction losses. This ensures the cooling system is adequately sized to prevent thermal runaway under all specified operating conditions.

2. How does the thermal resistance (Rth(j-c)) of the CM2500DY-24S impact system reliability?Its very low thermal resistance of 0.011 °C/W for the IGBT means that heat is evacuated from the semiconductor chip very efficiently. In practical terms, this reduces the peak temperature the chip experiences during power pulses and lowers the amplitude of thermal cycles, which is a primary factor in mitigating material fatigue and extending the operational lifetime of the module.

3. Can the CM2500DY-24S be paralleled for higher current applications?Yes, high-power modules like this are designed for paralleling. However, successful implementation requires careful attention to busbar layout to ensure symmetrical current sharing, and the gate drive circuit must be designed to provide simultaneous and identical turn-on/turn-off signals to each module. Mismatched Vce(sat) and gate threshold voltages can lead to imbalanced currents, so it is important to consult application notes on IGBT Paralleling for best practices.

4. What are the key considerations for the gate drive design for this 2500A module?Driving a high-current IGBT like the CM2500DY-24S requires a powerful gate driver capable of sourcing and sinking high peak currents to charge and discharge the gate capacitance quickly. A Kelvin emitter connection is provided and should be used to minimize the effect of stray inductance in the emitter path, ensuring cleaner switching and preventing parasitic turn-on. A gate voltage of +15V for turn-on and -10V to -15V for turn-off is typically recommended to ensure full enhancement and a robust off-state.

5. What is the impact of the internal stray inductance specified in the datasheet?The internal stray inductance (Ls), specified as approximately 15 nH, is a critical parameter for high-current, fast-switching applications. This inductance can cause voltage overshoots (Vce_peak = Vcc + Ls * di/dt) during turn-off. Designers must account for this by implementing low-inductance busbars and potentially using snubber circuits to clamp this overshoot and keep it within the module's safe operating area (SOA).

Design and Integration Guidance

The successful deployment of the CM2500DY-24S hinges on a holistic approach to system design that prioritizes thermal management from the outset. Engineers should focus on minimizing the thermal resistance of the interface between the module baseplate and the heatsink by selecting a high-performance thermal interface material (TIM) and ensuring proper mounting pressure for uniform contact. Furthermore, the layout of the DC link busbars should be carefully designed to minimize stray inductance, which is crucial for mitigating voltage overshoots during the rapid turn-off of 2500A currents. For a detailed exploration of these concepts, reviewing advanced resources on unlocking IGBT thermal performance can provide engineers with actionable insights to optimize their next high-power design.