Content last revised on January 11, 2026

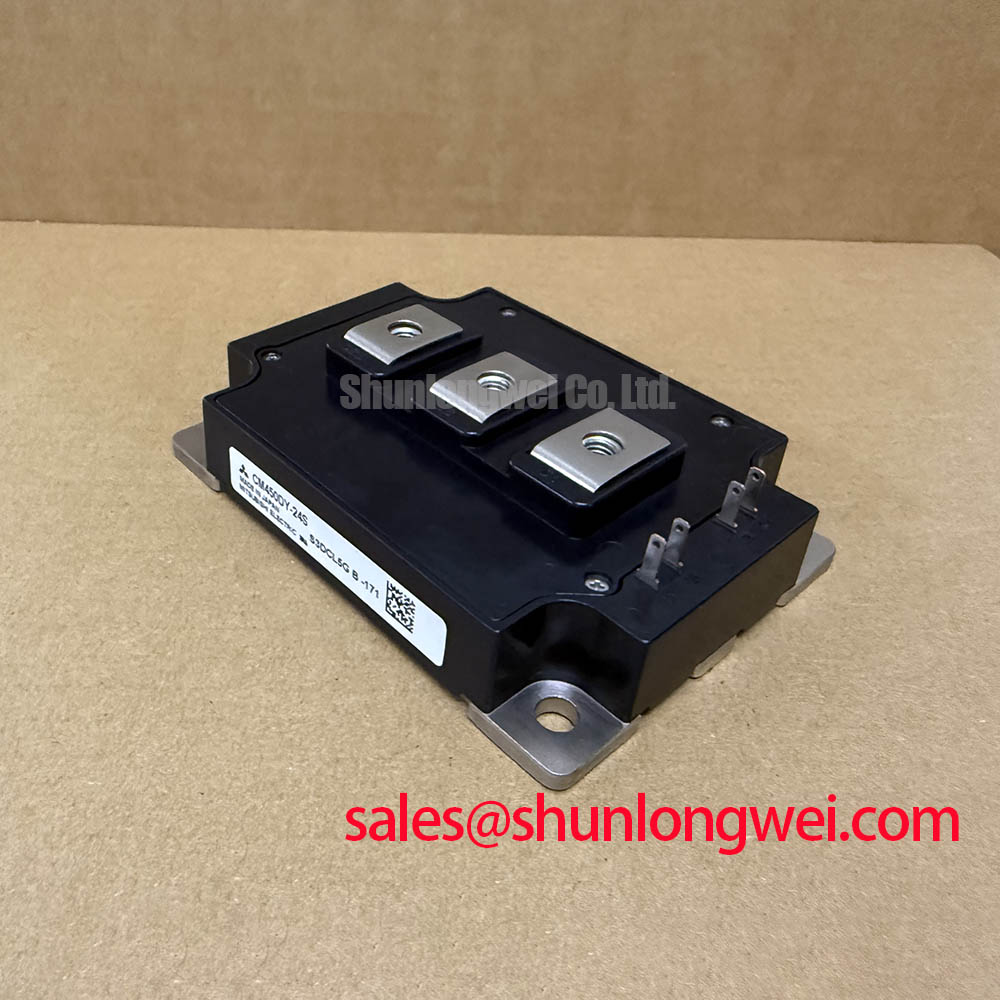

Mitsubishi CM450DY-24S: A 1200V 450A Dual IGBT Module Engineered for Thermal Reliability

An In-Depth Technical Review for High-Power Systems

The Mitsubishi CM450DY-24S is a dual IGBT module from the S-Series, engineered for superior thermal management and operational reliability in high-current power conversion systems. With core specifications of 1200V | 450A | Rth(j-c) 0.056°C/W, this device delivers two critical engineering benefits: enhanced thermal performance and robust short-circuit protection. It directly addresses the challenge of designing efficient and durable cooling systems for high-power density applications. For industrial motor drives over 150kW requiring robust thermal headroom, this module's low thermal resistance makes it a definitive choice.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Management

The technical specifications of the CM450DY-24S are optimized for demanding applications where thermal performance and electrical ruggedness are paramount. The parameters below highlight its capacity for high-current handling and its efficiency in managing heat dissipation, a critical factor for long-term system reliability.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Absolute Maximum Ratings (Tj = 25°C) | |||

| Collector-Emitter Voltage | VCES | - | 1200V |

| Collector Current (DC) | IC | TC = 25°C | 450A |

| Collector Current (Pulse) | ICP | 1ms pulse | 900A |

| Collector Power Dissipation | PC | TC = 25°C, per arm | 2200W |

| Electrical Characteristics (Tj = 25°C) | |||

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 450A, VGE = 15V | 2.7V (Max) |

| Gate-Emitter Threshold Voltage | VGE(th) | IC = 45mA, VCE = 10V | 5.5V (Typ) |

| Short-Circuit Withstand Time | tsc | VCC = 600V, VGE = 15V, Tj = 125°C | 10µs |

| Thermal Characteristics | |||

| Thermal Resistance (Junction-to-Case) | Rth(j-c) | IGBT per arm | 0.056°C/W |

| Thermal Resistance (Junction-to-Case) | Rth(j-c) | FWD per arm | 0.083°C/W |

Download the CM450DY-24S datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Drives and Renewable Energy Inverters

The CM450DY-24S is engineered for high-power, high-reliability applications where efficient power switching is critical. Its robust design and thermal characteristics make it an excellent component for the core of many power conversion systems.

- Industrial Motor Drives: In high-power Variable Frequency Drives (VFDs), the module's 450A continuous current rating and 900A peak capability are essential for controlling large induction motors. In a demanding scenario like a heavy-duty conveyor system, the module's ability to handle high inrush currents during motor startup and its robust Short Circuit Safe Operating Area (SCSOA) ensure operational reliability and prevent costly downtime.

- Solar and Wind Inverters: The efficiency of a renewable energy system is paramount. The low VCE(sat) of the CM450DY-24S minimizes conduction losses during the DC-AC inversion process. This translates directly to more deliverable energy and a better return on investment for large-scale solar farms or wind turbine installations.

- Uninterruptible Power Supplies (UPS): For data centers and critical industrial processes, the reliability offered by the 10µs short-circuit withstand time and low thermal impedance is a key advantage. It ensures the UPS can handle severe load faults without failure, safeguarding critical infrastructure.

The dual-switch configuration simplifies the design of half-bridge topologies, which are foundational for these applications. While the CM450DY-24S is a strong fit for this power range, for systems requiring even greater current capacity, the related CM600DX-24T offers a 600A rating within a similar voltage class.

Frequently Asked Questions (FAQ)

How does the low collector-emitter saturation voltage (VCE(sat)) of the CM450DY-24S contribute to overall system efficiency?

A lower VCE(sat) (2.7V max at 450A) means less voltage drops across the IGBT when it is fully turned on. This reduces the power lost as heat (conduction loss), directly improving the inverter's or converter's wall-plug efficiency. What is the primary benefit of the CM450DY-24S's low thermal resistance? It allows for smaller heatsinks and higher power density.

What is the practical engineering benefit of the module's low thermal resistance (Rth(j-c)) of 0.056°C/W when designing a cooling system?

This extremely low thermal resistance signifies highly efficient heat transfer from the IGBT silicon chip to the module's baseplate. For a design engineer, this means that for a given power dissipation, the chip's junction temperature will be significantly lower. This provides greater thermal margin, enhances long-term reliability, and can allow for the use of a smaller, more cost-effective heatsink, thereby increasing the system's overall power density.

What is the significance of the 10µs short-circuit withstand time rating for this module?

This rating is a critical reliability metric. It guarantees that the IGBT can survive a direct short-circuit condition—such as a motor phase-to-phase fault—for up to 10 microseconds. This provides a crucial time window for the system's protection circuitry to detect the fault and safely shut down the gate drive, preventing catastrophic failure of the module and protecting the entire system.

Technical Deep Dive

A Closer Look at Thermal Design for Long-Term Reliability

The performance of a high-power IGBT module is inextricably linked to its thermal management. The CM450DY-24S excels in this area due to its low thermal resistance, a key parameter that dictates reliability and power density. The Rth(j-c) value of 0.056°C/W for the IGBT is a direct measure of how effectively heat generated at the semiconductor junction can be transferred to the case. Think of thermal resistance like the width of a highway. This low value is like a wide, multi-lane superhighway, allowing the 'traffic' of heat to flow away from the silicon chip quickly and efficiently. A higher thermal resistance would be a narrow country lane, causing heat to back up and leading to a rapid rise in junction temperature.

This efficiency is complemented by the module's low conduction losses, governed by its VCE(sat). This parameter acts like a tollbooth for the electrical current. The lower the toll (the VCE(sat) value, here a maximum of 2.7V at rated current), the less energy the current loses as it passes through the switch. This directly translates to less wasted heat being generated in the first place. When combined, a low VCE(sat) and a low Rth(j-c) create a virtuous cycle: less heat is generated, and the heat that is generated is removed more effectively. This synergy is fundamental to designing compact and reliable power electronics, such as those discussed in guides to IGBT thermal performance. This allows engineers to push operational limits safely or to design systems with greater longevity and lower field failure rates.

To further explore and specify the Mitsubishi CM450DY-24S for your power conversion project, or to discuss its integration with your system's thermal and gate drive design, please reach out to our technical support team for detailed assistance and procurement information.