Content last revised on November 7, 2025

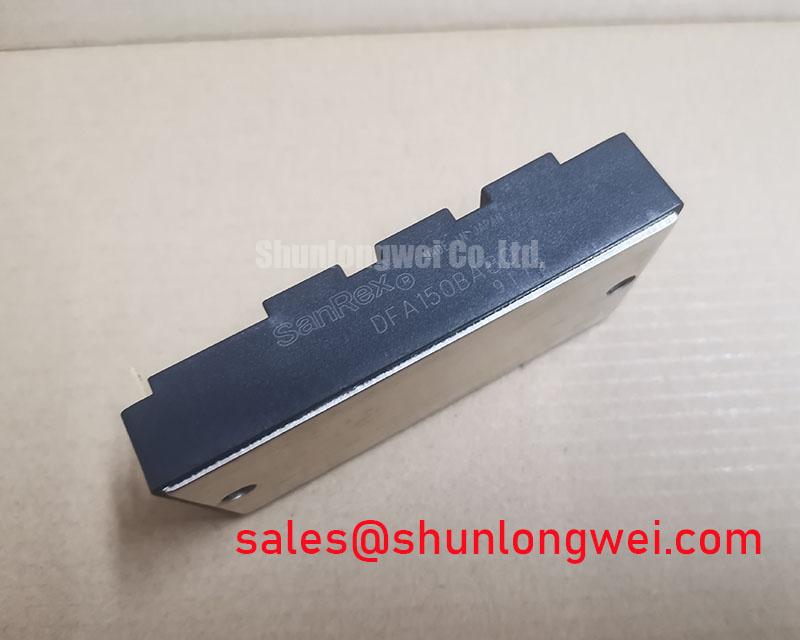

DFA150BA80: High-Reliability 800V, 150A Three-Phase Diode Rectifier Module

Engineering a Thermally Stable Power Core

An Expert Review of the DFA150BA80 Diode Module for Demanding Industrial Applications

The DFA150BA80 is a high-current, three-phase diode bridge rectifier engineered for superior thermal performance and operational longevity in high-stress power conversion systems. Its core value proposition lies in a design that prioritizes efficient heat dissipation, enabling robust and reliable performance under continuous heavy loads. With key specifications of 800V | 150A | Rth(j-c) 0.16 K/W, this module provides two critical engineering benefits: enhanced system reliability and simplified thermal management. It directly addresses the challenge of maintaining stable operation in equipment like industrial motor drives and power supplies where thermal runaway is a primary failure mode. For systems requiring robust front-end rectification up to 800V with a focus on thermal margin, the DFA150BA80 is an excellent engineering choice.

Key Parameter Overview

Decoding the Specs for Thermal Management and Electrical Robustness

The specifications of the DFA150BA80 are tailored for high-power industrial environments. The parameters below highlight its capacity for robust electrical performance and, critically, its excellent thermal transfer characteristics, which form the foundation of its reliability.

| Parameter | Symbol | Value | Conditions |

| Repetitive Peak Reverse Voltage | VRRM | 800 V | - |

| Average Forward Current | IF(AV) | 150 A | Three Phase, TC = 105°C |

| Peak Forward Surge Current | IFSM | 1500 A | 50Hz, 1 cycle, non-repetitive |

| Forward Voltage Drop | VFM | 1.35 V | IFM = 150A, Tj = 25°C |

| Thermal Resistance (Junction to Case) | Rth(j-c) | 0.16 K/W | Per Diode |

| Isolation Voltage | Viso | 2500 V | Terminals to Base, AC 1 min. |

| Operating Junction Temperature | Tj | -40 to +150 °C | - |

Download the DFA150BA80 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in High-Power Industrial Rectification

The DFA150BA80 is engineered for the input stages of high-power conversion systems where reliability and thermal stability are non-negotiable. Its primary applications include the front-end rectifiers for Variable Frequency Drives (VFDs), industrial power supplies, battery charging infrastructure, and Uninterruptible Power Supply (UPS) systems.

What is the main benefit of the DFA150BA80's low thermal resistance? It ensures superior heat transfer, leading to higher system reliability.

Consider the engineering challenge of designing the front-end for a 75 kW industrial motor drive. The rectifier stage must handle not only the continuous nominal current but also withstand inrush currents and load fluctuations without overheating. The DFA150BA80's low Thermal Resistance of 0.16 K/W provides a highly efficient path for waste heat to move from the semiconductor junction to the heatsink. This allows engineers to design a more compact and cost-effective cooling system, improve power density, and significantly enhance the long-term reliability of the entire drive by keeping the diode junction temperature well within its safe operating limits.

For systems requiring higher current handling, the related DF200BA80 offers a 200A capability in a similar package. For applications connected to higher voltage lines, such as 690V industrial grids, the DF150AE160 provides a blocking voltage of 1600V.

Technical Deep Dive

A Closer Look at the Thermal Path for Enhanced System Longevity

The long-term reliability of a power module is fundamentally tied to its thermal management strategy. The DFA150BA80's design reflects a deep understanding of this principle. The module incorporates a high-conductivity copper baseplate, which serves as the primary interface to the external heatsink. This construction minimizes the thermal boundary resistance, ensuring that heat generated within the six diodes is spread effectively and transferred efficiently to the cooling apparatus.

The key specification here is the junction-to-case Thermal Resistance (Rth(j-c)). A low Rth(j-c) value of 0.16 K/W per diode is analogous to having a wide, unobstructed pipeline for heat to flow out of the silicon. A higher thermal resistance would be like a narrow, constricted pipe, causing a "backup" of heat and a rapid rise in junction temperature under load. By providing this low-resistance thermal path, the DFA150BA80 allows designers to maintain a lower operating junction temperature for a given power dissipation, which directly correlates to a longer component lifetime and improved resilience to power cycling stress.

Frequently Asked Questions (FAQ)

How does the 0.16 K/W thermal resistance impact heatsink selection?A lower thermal resistance like 0.16 K/W means the module transfers heat more efficiently from the internal diode junction to the module case. This efficiency allows engineers to potentially use a smaller, lighter, and less costly heatsink to maintain the same target junction temperature, or achieve a lower operating temperature with a standard heatsink, thereby increasing the system's reliability and power density.

What is the significance of the 2500V isolation voltage?The 2500V isolation rating ensures a high degree of electrical safety by preventing current from leaking between the electrically live terminals and the metal baseplate, which is typically mounted to a grounded chassis or heatsink. This is a critical safety feature in industrial equipment, protecting against electric shock and preventing ground faults that could damage the system.

Is this module suitable for applications with high inrush currents?Yes, it is well-suited for such applications. The DFA150BA80 features a high Peak Forward Surge Current (IFSM) rating of 1500A for a single 50Hz cycle. This high surge capability allows it to safely handle the large, brief inrush currents typically encountered during the startup of motors or the charging of large capacitor banks in power supplies and UPS systems, preventing rectifier failure.

This module's robust design and excellent thermal characteristics provide a solid foundation for building reliable, long-lasting power conversion systems. Its specifications are not just numbers, but direct enablers of more efficient, compact, and resilient industrial electronics.